Automatic-control accelerating device for filter rod sending unit

A technology for accelerating device and filter rod emission, which is applied in the directions of comprehensive factory control, electrical program control, and comprehensive factory control. The effect of high system stability and convenient debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

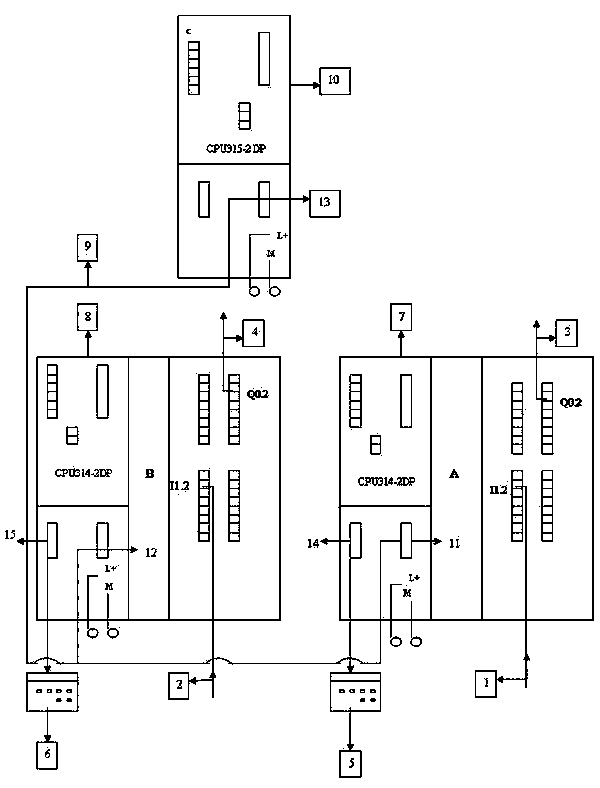

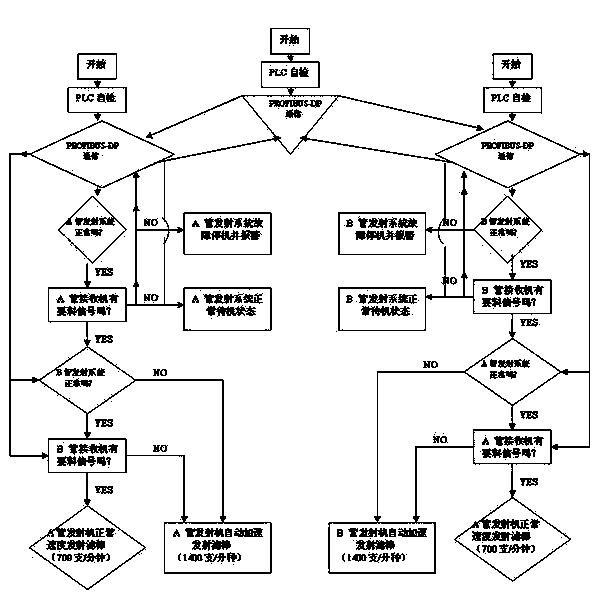

[0023] Attached below figure 1 , 2 The present invention is described in detail:

[0024] An automatic control acceleration device for a filter rod transmitter unit, which includes a tube A receiving signal module 1, a tube B receiving signal module 2, a tube A transmitting system fault signal module 3, and a tube B transmitting system fault signal module 4 , A tube launch system text display 5, B tube launch system text display 6, A tube launch system PLC controller 7, B tube launch system PLC controller 8, network bus PROFIBUS-DP9, master station PLC controller 10, A tube DP communication port 11 of the launch system PLC, DP communication port 12 of the tube B launch system PLC, DP communication port 13 of the main station PLC, MPI communication port 14 of the A tube launch system PLC, and MPI communication port 15 of the B tube launch system PLC ;

[0025] The A pipe receives the required material signal module 1 and connects the I1.1 port of the A pipe launching system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com