Tag binding machine

A technology of binding machine and tag, applied in the directions of packaging, transportation and packaging, labeling, etc., can solve the problems of low manual efficiency of tag binding machine, etc., and achieve the effect of compact structure, cost saving and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

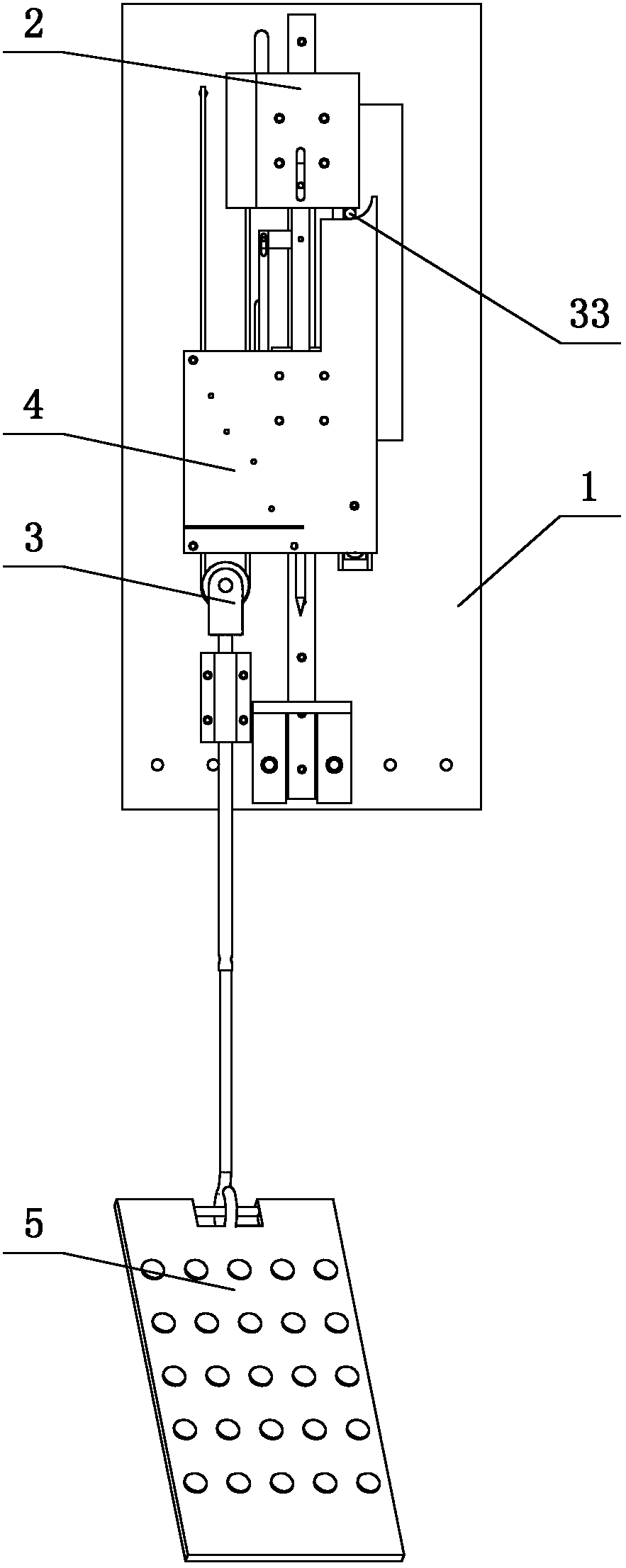

[0025] refer to figure 1 It is an embodiment of a hanging tag binding machine of the present invention, a hanging tag binding machine, including a frame 1, a linkage assembly 2 slidably arranged on the frame 1, a differential power assembly 3 that drives the movement of the linkage assembly 2, and a linkage assembly 2 drives the rubber needle extruding mechanism 4, and the differential power assembly 3 is connected with a foot pedal 5 to drive its movement.

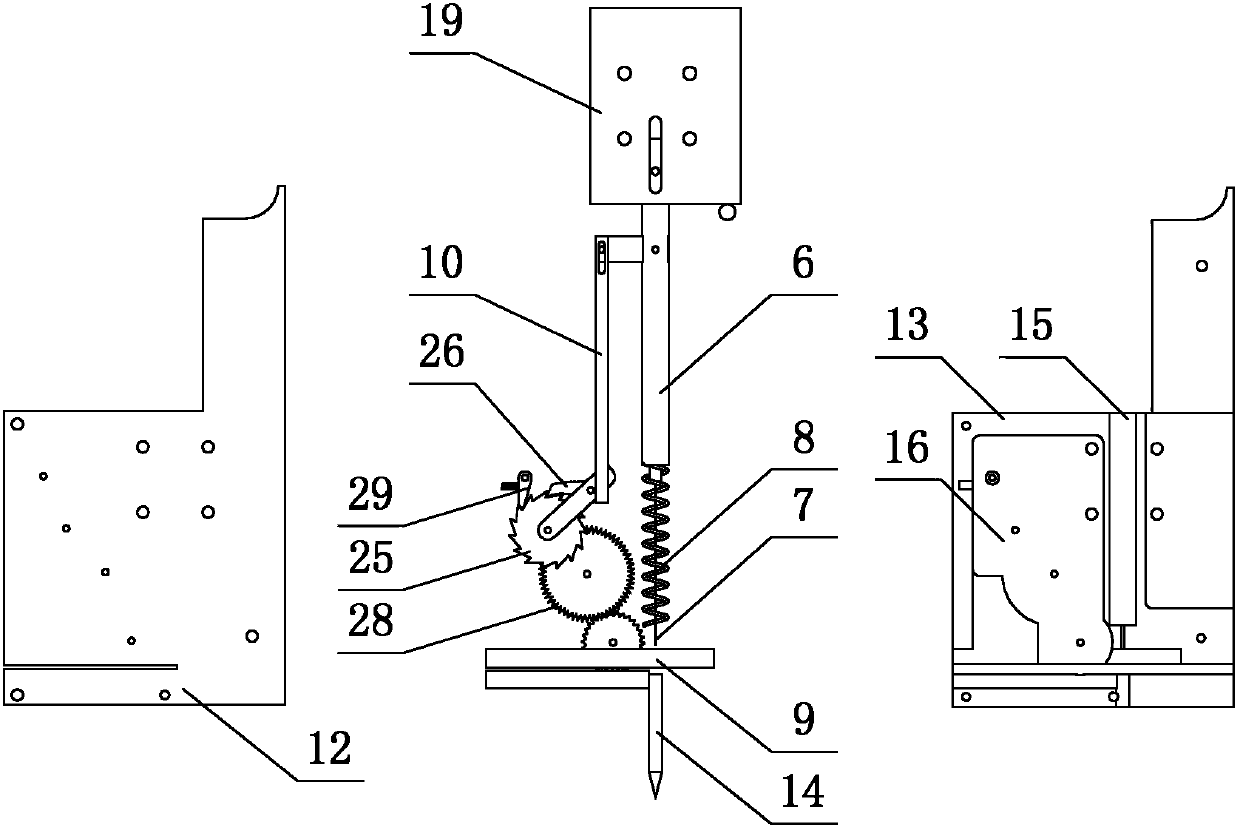

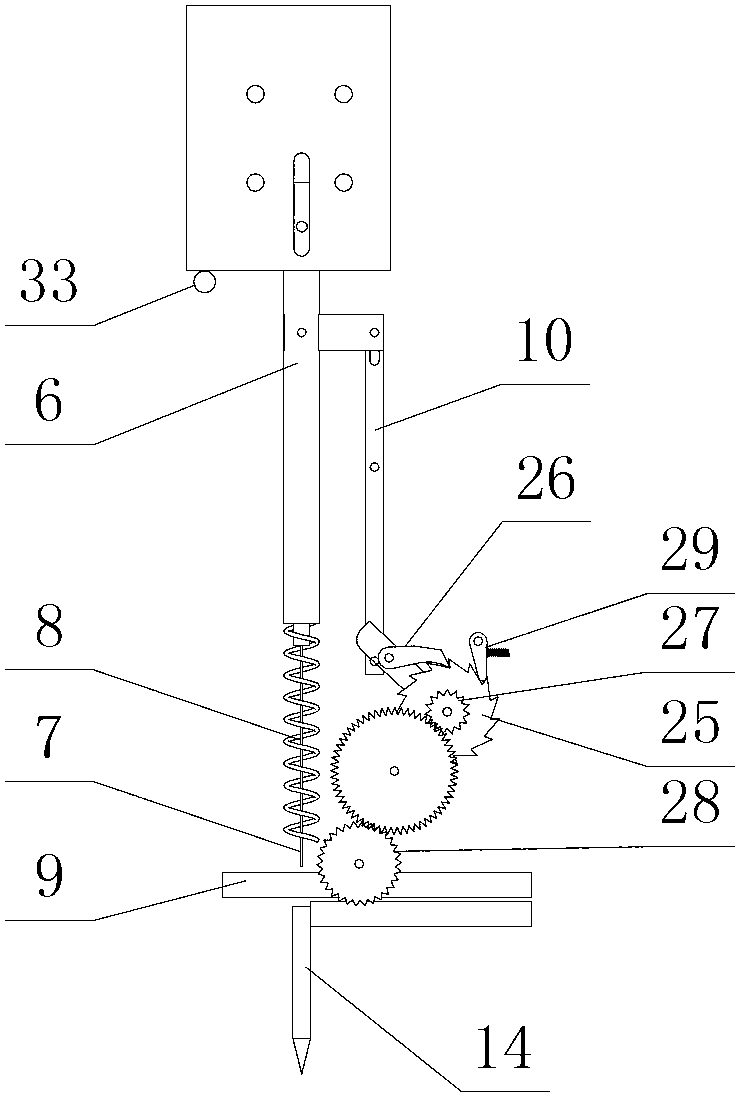

[0026] Such as Figure 2 to Figure 4 As shown, the rubber needle extrusion mechanism 4 includes a rubber needle push rod 6, a rubber needle push head 7 is fixed under the rubber needle push rod 6, and a first pressure spring 8 is covered on the rubber needle push head 7, The top of the first compression spring 8 is pushed against the bottom of the rubber needle push rod 6; it also includes a bullet partition 9 and a push mechanism for pushing the bullet forward, and the rubber needle push rod 6 is provided with a mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com