Method and device for knotting the ends of a thread to flat articles

An object and flat technology, which is applied in the field of knotting on flat objects at the wire end, can solve problems such as limited working speed, complicated movement process, and complicated methods, and achieve the effect of improving working speed and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

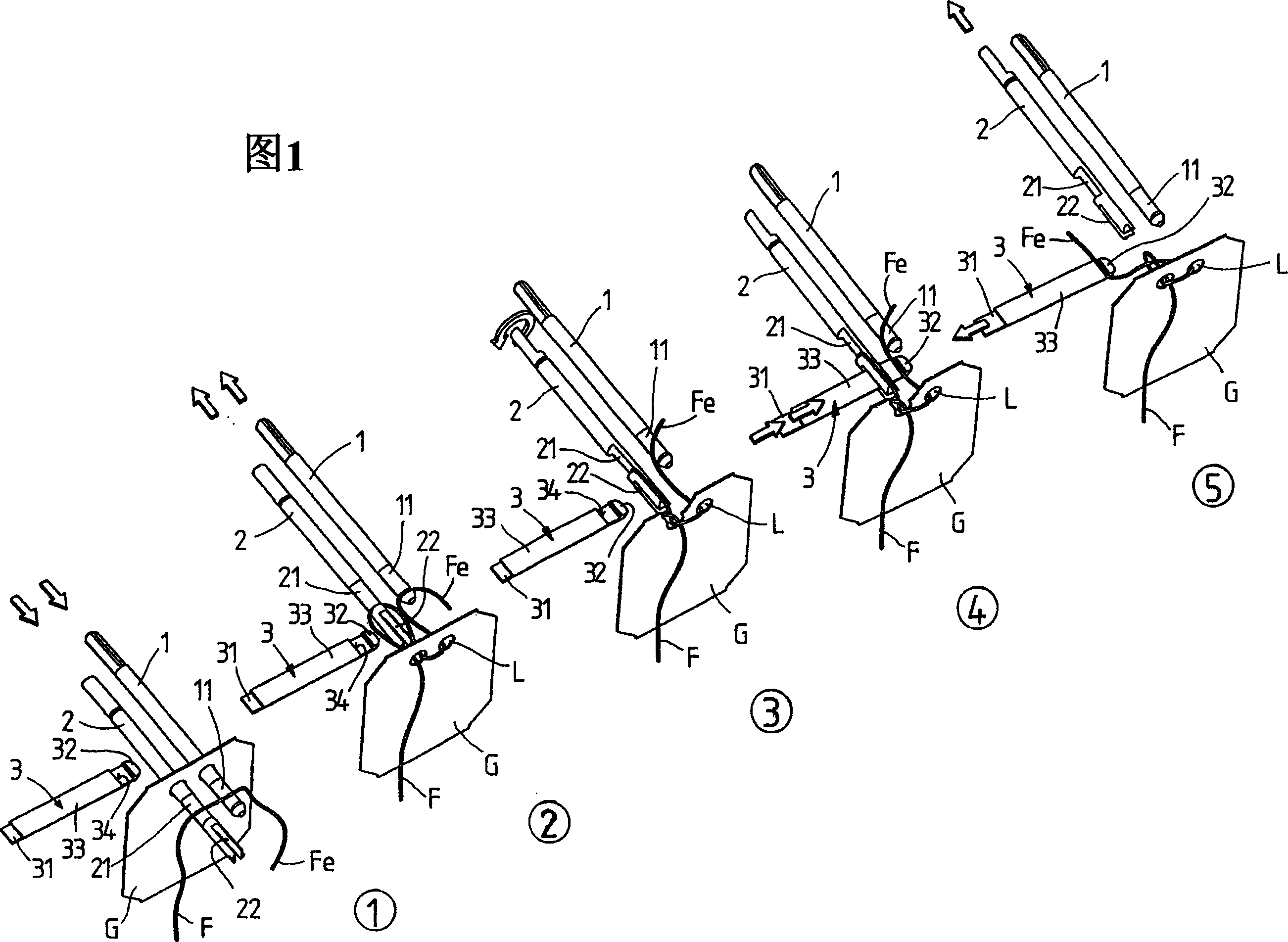

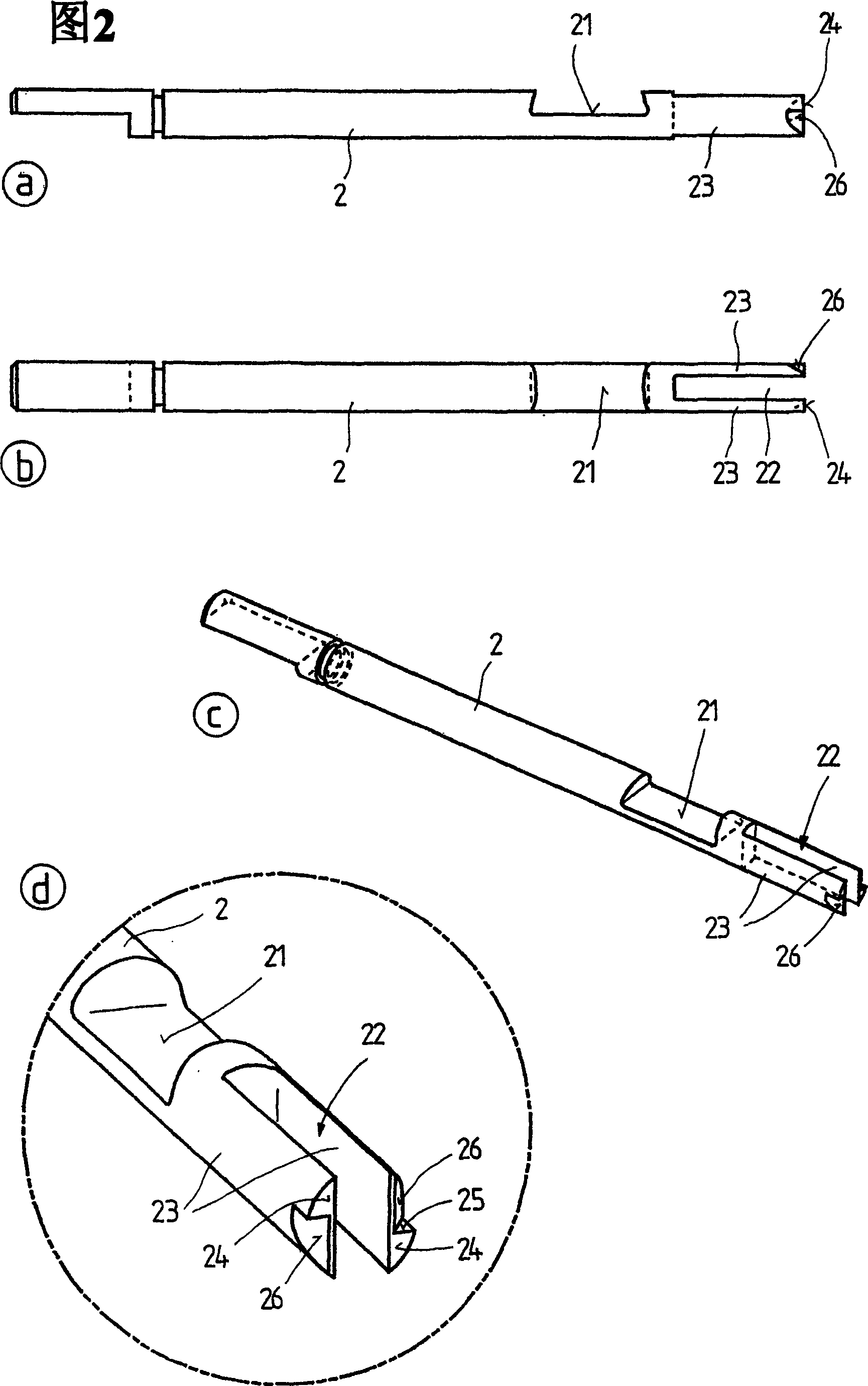

[0020] FIG. 1 shows a device for knotting a thread F end on a flat object G in the form of a label, which comprises three tools, namely a first rod 1 , a second rod 2 and a gripper 3 . These three tools are shown schematically and exploded in five different positions in FIG. 1 . FIG. 2 shows a side view (a), a top view (b), a perspective view (c) of the rod 2 and a detail (d) in relation to its end-side configuration.

[0021] As can be seen from FIG. 1 , the bars 1 and 2 are distributed parallel to and at a distance from each other; the gripper 3 moves at right angles to the plane in which the bars 1 and 2 are located.

[0022] As can be seen from Figure 1, the rod 1 moves between a front end position (see Figure 1.1) and a rear end position (see Figures 1.2-1.5). It has a hook-shaped notch 11 on the front end for receiving the thread F.

[0023] The second rod 2 also has such a notch 21 forming a hook, but the end of the second rod has a perforation formed as an opening 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com