Thread material cutting device

一种切断装置、线材的技术,应用在层压装置、包装、包装食品等方向,能够解决通水过滤性片破裂等问题,达到消除破裂、紧凑装置结构、削减运行成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

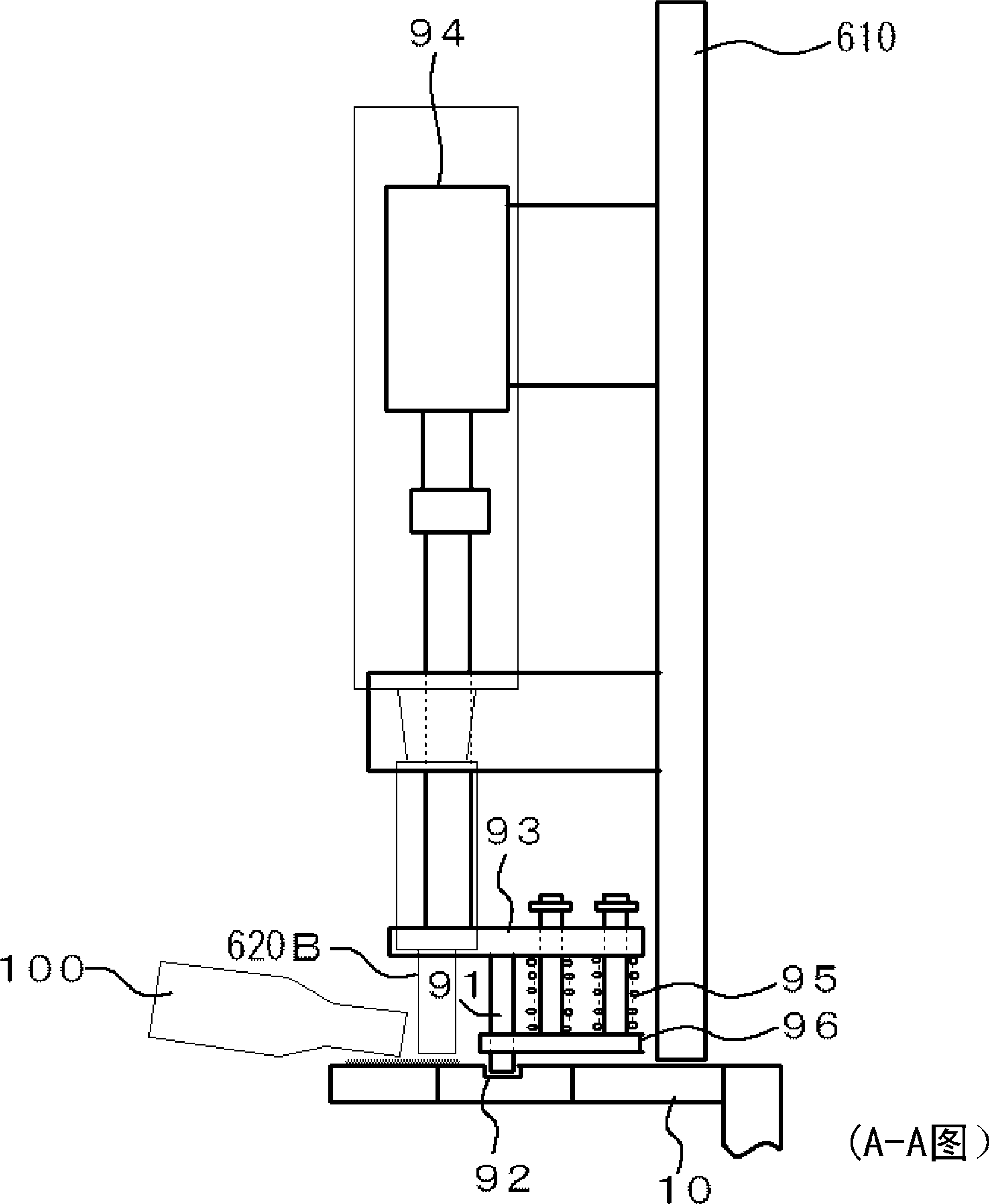

[0033] Below, while referring to the attached Figure 1 The present invention will be described in detail. In addition, in each figure, the same code|symbol represents the same or equivalent structural element.

[0034] figure 1 It is an overall configuration diagram of a sheet manufacturing apparatus 1 for an infusion bag according to an embodiment of the present invention equipped with a wire rod cutting device according to an embodiment of the present invention, and a filling and packaging machine 70 installed continuously therewith.

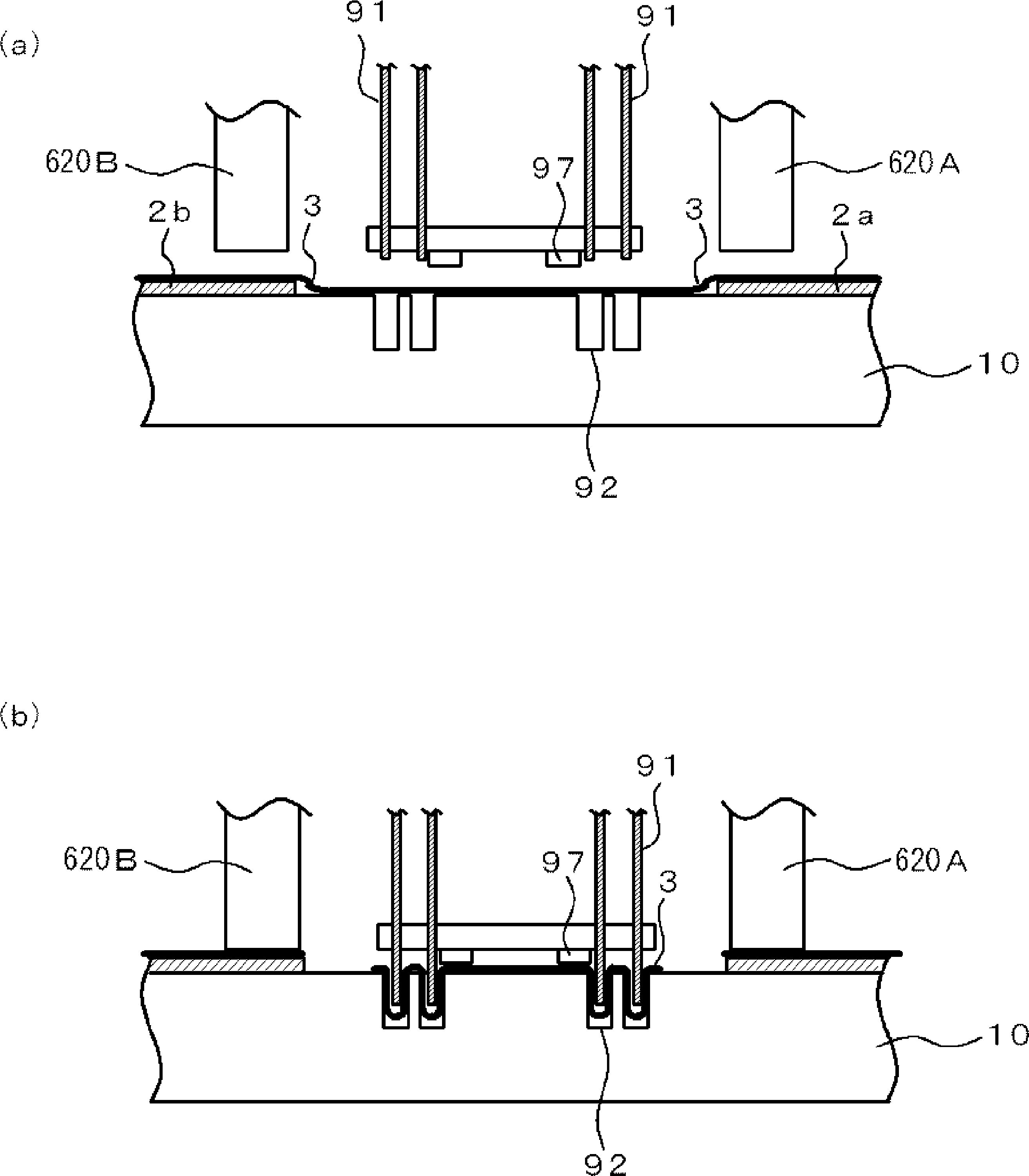

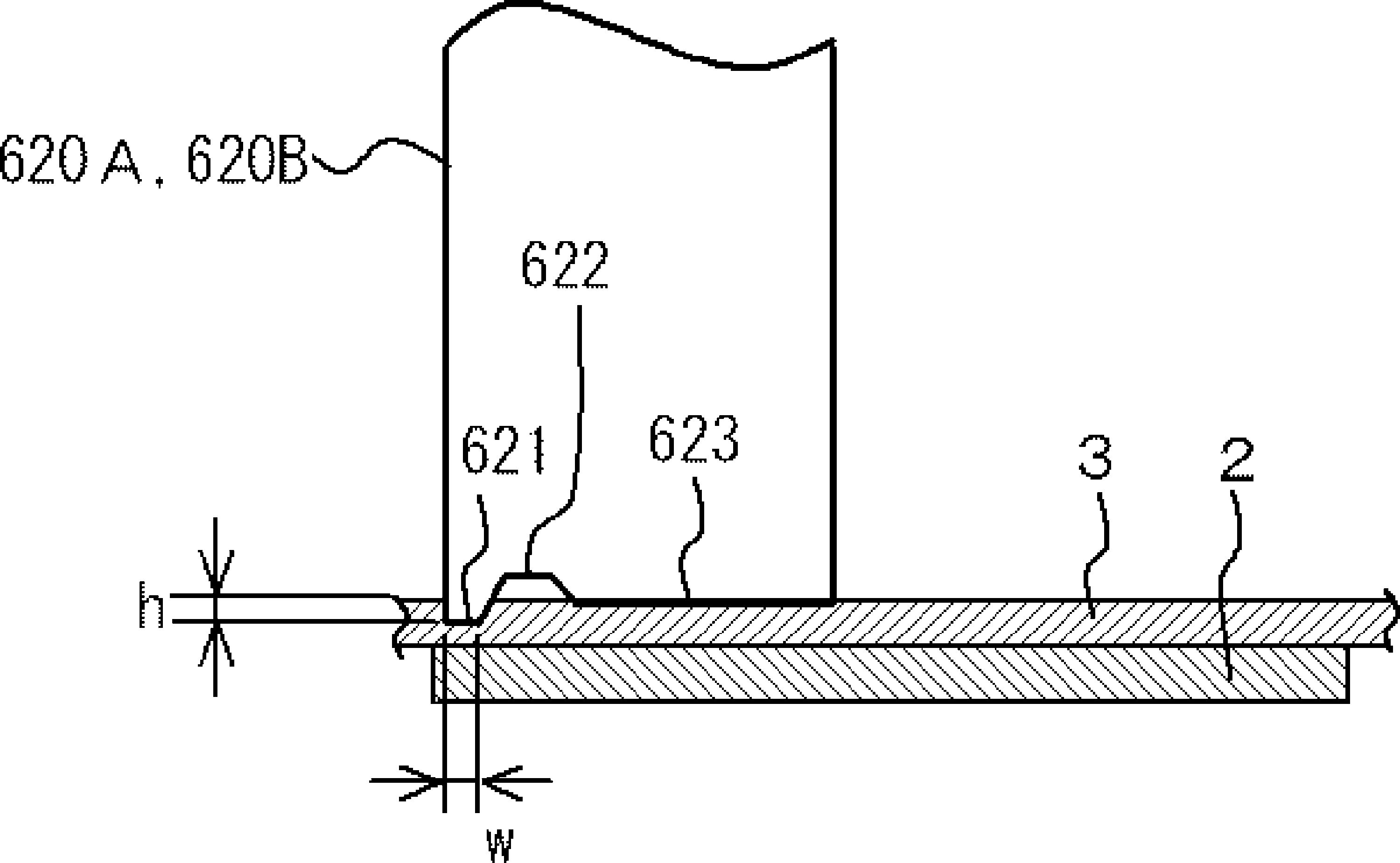

[0035] The sheet manufacturing device 1 for the infusion bag is as figure 2 Shown is an apparatus for manufacturing an infusion bag sheet 5 in which labels 2 welded to wires 3 are arranged at predetermined intervals in the longitudinal direction of a water-permeable filter sheet 4 . In this figure, the dashed-two dotted line represents a portion that is horizontally sealed during manufacture of the infusion bag, and each area demarcated b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com