Device for dispensing plastic fasteners

A fastener and firmware technology, used in packaging, fixing labels, transportation and packaging, etc., can solve problems such as inefficiency, ineffective use of energy, and limited use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

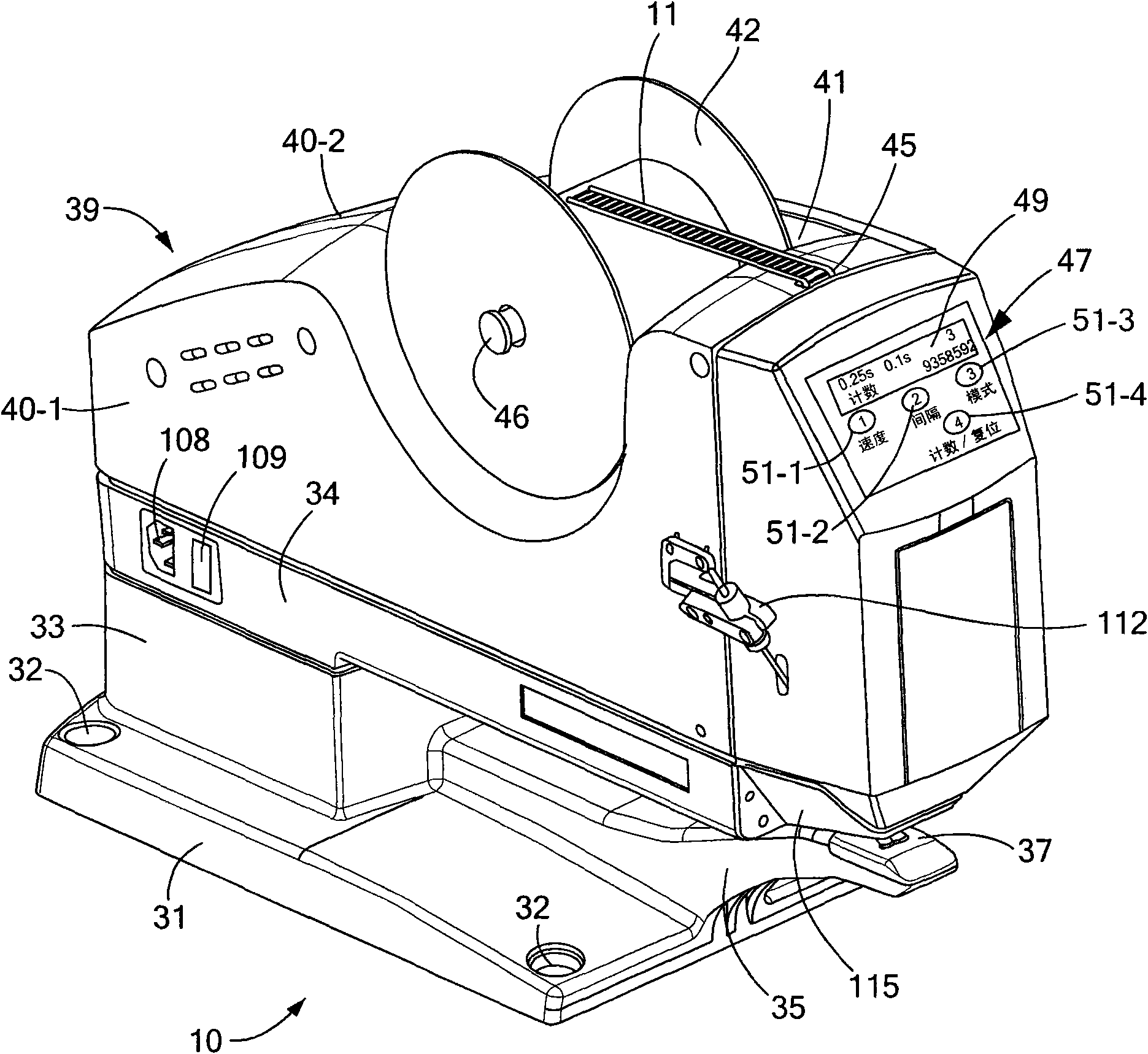

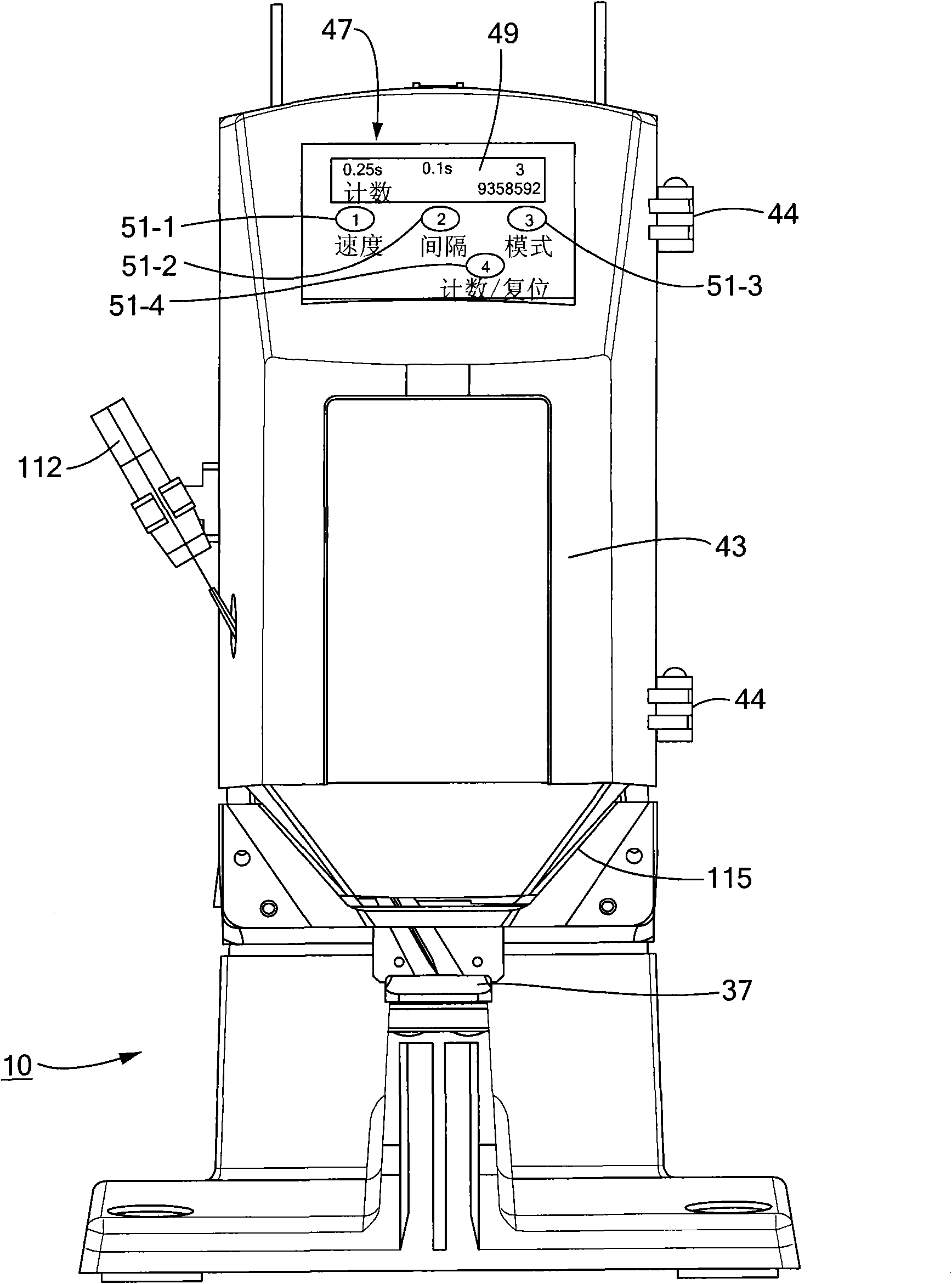

[0043] [0043] Now refer to figure 1 , which shows a device for dispensing individual plastic fasteners from a continuously connected ladder-like supply, manufactured in accordance with the invention and generally designated by the reference numeral 10 . As can be appreciated, the device 10 may be used, for example, in an automated packaging line to secure two or more products together using one or more plastic fasteners from a ladder stock, the two or more products such as socks, gloves, towels or other similar items. For the purpose of simplicity and clarity, components not directly pertaining to the invention are only schematically shown in the figures and will not be described in detail below.

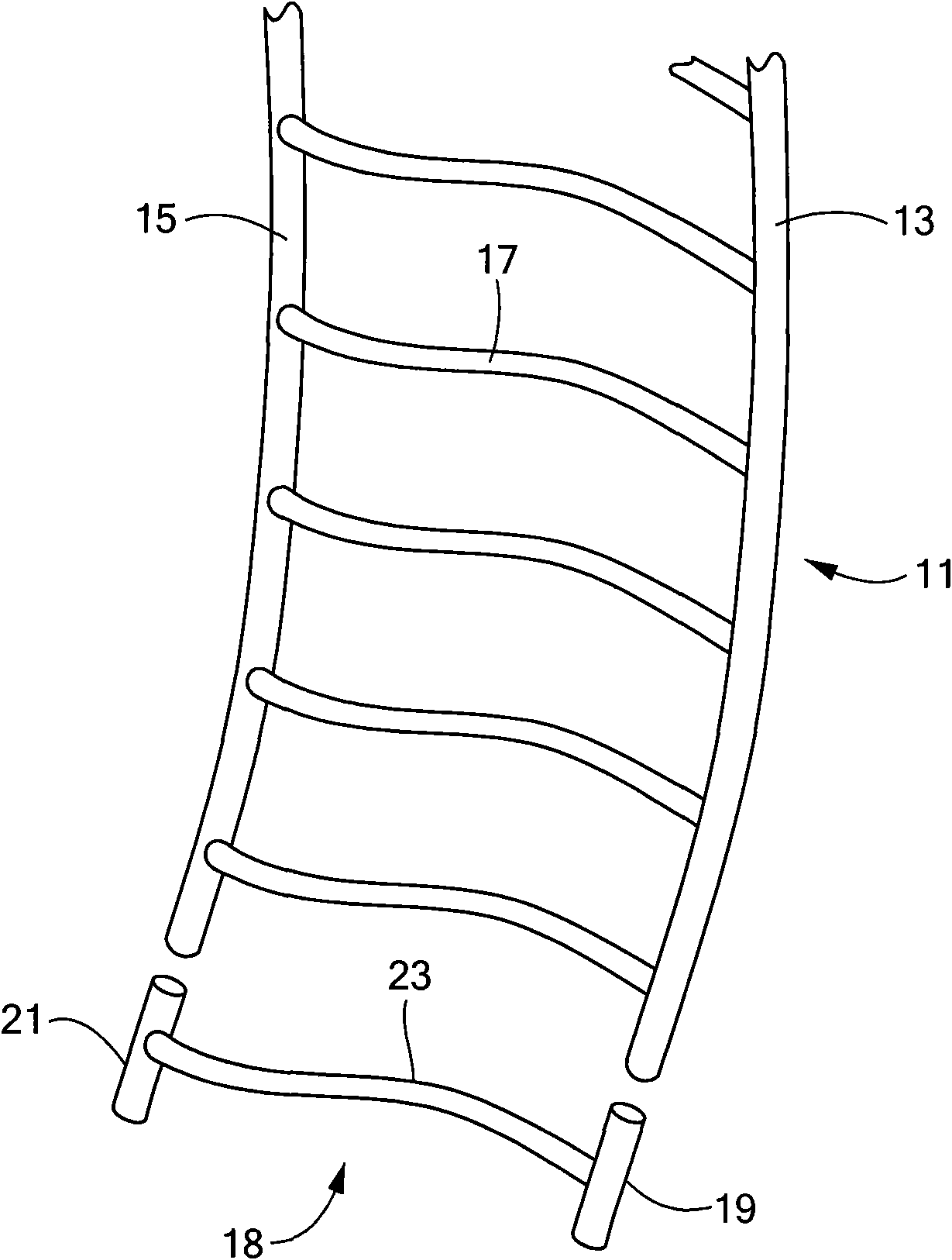

[0044] Continuous supply of ladder goods 11

[0045] [0044] As noted above, the device 10 is designed to dispense individual plastic fasteners from various types of continuously connected ladder stock. For example, the supply of ladder stock (also referred to herein as fastener s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com