Method for preparing interior wall putty powder from semi-dry desulfurization ash

A semi-dry method of desulfurization and interior wall putty powder technology, which is applied in the direction of filling slurry, etc., can solve the problems of low utilization rate of desulfurization ash, lower product competitiveness, complicated processing procedures, etc., and achieve good construction performance, low cost, The effect of shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Screen the semi-dry desulfurization ash with a 50-mesh square hole sieve; 80 parts of the semi-dry desulfurization ash, 20 parts of white cement, 2.8 parts of redispersible latex powder, hydroxypropyl methyl Mix 0.3 parts of base cellulose ether and 0.02 parts of starch ether and stir for 10 minutes to prepare interior wall putty powder. The white cement is white Portland cement, grade PW32.5, whiteness ≥ 90, the fineness of the hydroxypropyl methylcellulose ether is 150 μm square hole sieve balance ≤ 1.5%, the The fineness of starch ether is 500μm square hole sieve balance ≤ 5%.

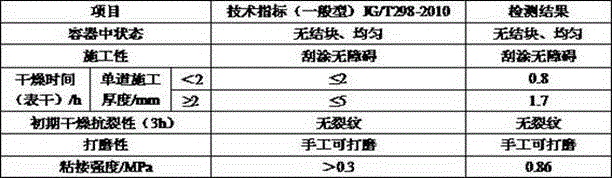

[0025] The interior wall putty powder prepared according to the present invention is formulated into a slurry according to the ratio of putty powder: water = 1:0.5, and tested according to JG / T298-2010 "Putty for Building Interiors", and the results are shown in Table 1.

[0026] Table 1

[0027]

[0028] The results show that the performance of the prepared interior wall putty powder me...

Embodiment 2

[0030] Sieve the semi-dry desulfurization ash with a 200-mesh square hole sieve; 90 parts of semi-dry desulfurization ash, 10 parts of ash calcium powder, 0.8 parts of ethylene / vinyl acetate copolymer, 0.2 parts of polyvinyl alcohol, 0.35 parts of hydroxypropyl methylcellulose ether, and 0.04 parts of starch ether were mixed and stirred for 8 minutes to prepare an interior wall putty powder. The polyvinyl alcohol is polyvinyl alcohol 1788, and the gray Calcium powder fineness is 40 μm square hole sieve balance ≤ 5%, whiteness ≥ 90, said hydroxypropyl methyl cellulose ether fineness is 150 μm square hole sieve balance ≤ 1.5%, said starch Ether fineness is 500μm square hole sieve balance ≤ 5%.

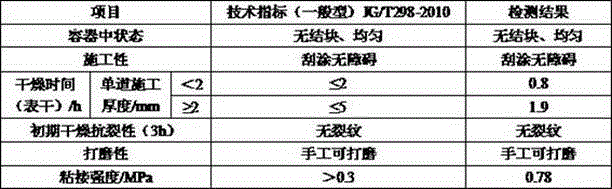

[0031] The interior wall putty powder prepared according to the present invention is formulated into a slurry according to the ratio of putty powder: water = 1:0.5, and tested according to JG / T298-2010 "Putty for Building Interiors", and the results are shown in Table 2.

[0032] Table ...

Embodiment 3

[0036] Sieve the semi-dry desulfurization ash with a 400-mesh square hole sieve; 100 parts of the semi-dry desulfurization ash, 5 parts of redispersible latex powder, 0.1 part of polyvinyl alcohol, hydroxypropyl Mix 0.35 part of methyl cellulose ether and 0.05 part of starch ether and stir for 5 minutes to prepare interior wall putty powder. The polyvinyl alcohol is polyvinyl alcohol 2488.

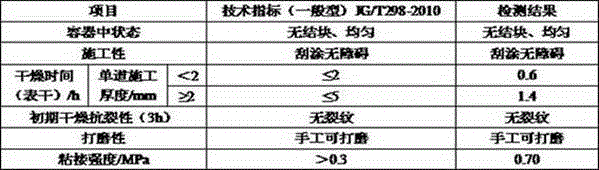

[0037] The interior wall putty powder prepared according to the present invention is made into a slurry according to the ratio of putty powder: water = 1:0.5, and the test is carried out according to JG / T298-2010 "Putty for Building Interior". The results are shown in Table 3.

[0038] table 3

[0039]

[0040] The results show that the performance of the prepared interior wall putty powder meets the general technical indicators of the standard JG / T298-2010.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com