Texture paint decoration prefabricated coiled material for exterior wall of building and method for preparing same

A technology for building exterior walls and textured paint, which is applied in the direction of architecture, building structure, chemical instruments and methods, etc. It can solve the problems of prolonging the construction period, cracks in the decorative layer, increasing quality, etc., and achieves the improvement of compactness and strength, and impermeability Good waterproof performance and good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

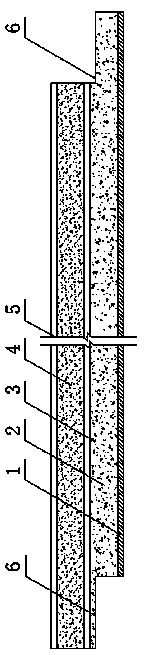

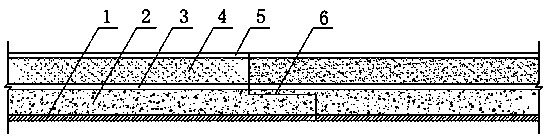

[0024] Such as figure 1 As shown, a prefabricated roll material decorated with texture paint for building exterior walls includes an organic polymer non-woven fabric bearing layer 1, a tough base material layer 2 is arranged on the organic polymer non-woven fabric bearing layer 1, and a tough base material layer is formed on the tough base material layer. 2, a waterproof primer layer 3 is sprayed, a texture paint main paint layer 4 is arranged on the waterproof primer layer 3, and a finish paint layer 5 is arranged on the texture paint main paint layer 4. Such as figure 2 As shown, step surfaces 6 are set on the edges of both sides of the prefabricated coil decorated with texture paint for the exterior wall of the building, wherein the step surface 6 on one side is arranged on the top surface of the prefabricated coil decorated with texture paint for the exterior wall of the building, and the steps on the other side The surface 6 is arranged on the bottom surface of the pref...

Embodiment 2

[0040] The similarities between this example and Example 1 will not be repeated, and the difference is: the preparation of the tough substrate layer: the A emulsion is made of polyvinyl acetate homopolymer emulsion, and the B emulsion is made of styrene-butadiene emulsion. The tough substrate layer includes the following components in parts by weight (the total dry matter is 1000 parts): 265 parts of subnanometer nickel-iron blast furnace slag superfine powder; 452 parts of quartz sand from 80 mesh to 150 mesh; 52.5R silicate 235 parts of cement; 1 part of hydroxypropyl methylcellulose; 130 parts of 30% solid content polyvinyl acetate homopolymer emulsion; 40 parts of 20% solid content styrene-butadiene emulsion; 125 parts of water.

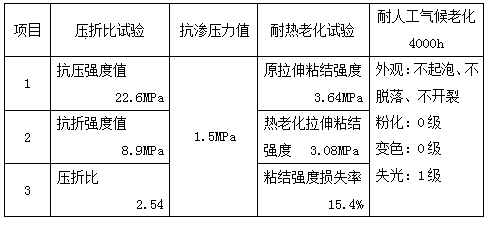

[0041] Table 2 is the relevant performance test data of embodiment 2 tough base material: Table 2

[0042]

[0043] It can meet the requirements of production preparation and end product quality. Part of the softness and impermeability are re...

Embodiment 3

[0045] The similarities between this example and Example 1 will not be repeated, and the difference is: the preparation of the tough substrate layer A emulsion is made of polyurethane emulsion, and B emulsion is made of vinyl acetate and acrylate copolymer emulsion. The tough substrate layer comprises the following components in parts by weight (the total amount of dry matter is 1000 parts):

[0046] 240 parts of sub-nanometer nickel-iron blast furnace slag superfine powder;

[0047] 458 parts of quartz sand from 80 mesh to 150 mesh;

[0048]260 parts of 52.5R Portland cement;

[0049] 1.2 parts of hydroxypropyl methylcellulose;

[0050] 80 parts of 30% solid content polyurethane emulsion;

[0051] 70 parts of 24% solid content vinyl acetate and acrylate copolymer emulsion;

[0052] 137 parts of water.

[0053] Table 3 is the relevant performance test data of embodiment 3 tough base material: Table 3

[0054]

[0055] It can meet the requirements of production prepara...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com