Light foaming TPU shoe sole and manufacturing process thereof

A lightweight and high-tech technology, applied to soles, footwear, footwear, etc., can solve the problems of inconvenient protection of soles, short service life, and displacement of insoles, so as to prevent wrong walking posture, improve service life, and be safe and convenient to use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

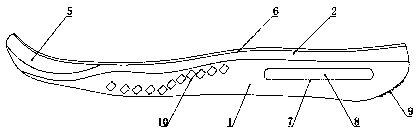

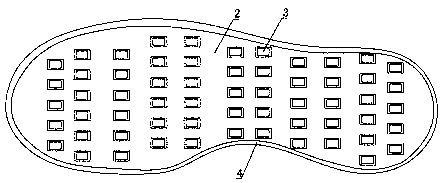

[0041] Such as Figure 1-3 As shown, the present invention provides a technical solution, a lightweight foamed TPU sole, including a TPU sole matrix 1, a foam pad 2 bonded to the top of the TPU sole matrix 1, a number of cavities 3 are provided at the bottom of the foam pad 2, and the foam Adhesive layer 4 is bonded to the edge of pad 2. In order to facilitate normal connection and improve foot feel, cavity 3 is square and arranged around the sole of foam pad 2. The width of adhesive layer 4 is 1.2 cm. The front end of foam pad 2 A resin layer 5 is embedded and bonded, and an insole layer 6 is bonded to the top of the foam pad 2;

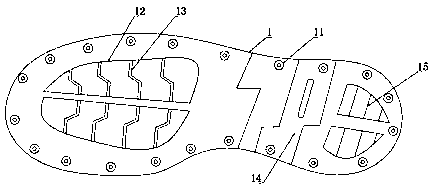

[0042] A shock-absorbing chamber 7 is provided at the rear heel position of the TPU sole matrix 1, and the interior of the shock-absorbing chamber 7 is filled with elastic cotton 8, and a plurality of TPU foamed particles 10 are embedded in the sole of the TPU sole matrix 1;

[0043] The heel of the TPU sole matrix 1 is provided with a wear-resista...

Embodiment 2

[0046] Such as Figure 1-3As shown, the present invention provides a technical solution, a lightweight foamed TPU sole, including a TPU sole matrix 1, a foam pad 2 bonded to the top of the TPU sole matrix 1, a number of cavities 3 are provided at the bottom of the foam pad 2, and the foam Adhesive layer 4 is bonded to the edge of pad 2. In order to facilitate normal connection and improve foot feel, cavity 3 is square and arranged around the sole of foam pad 2. The width of adhesive layer 4 is 1.0 cm. The front end of foam pad 2 A resin layer 5 is embedded and bonded, and an insole layer 6 is bonded to the top of the foam pad 2;

[0047] A shock-absorbing chamber 7 is provided at the rear heel position of the TPU sole matrix 1, and the interior of the shock-absorbing chamber 7 is filled with elastic cotton 8, and a plurality of TPU foamed particles 10 are embedded in the sole of the TPU sole matrix 1;

[0048] The heel of the TPU sole matrix 1 is provided with a wear-resistan...

Embodiment 3

[0051] Such as Figure 1-3 As shown, the present invention provides a technical solution, a lightweight foamed TPU sole, including a TPU sole matrix 1, a foam pad 2 bonded to the top of the TPU sole matrix 1, a number of cavities 3 are provided at the bottom of the foam pad 2, and the foam Adhesive layer 4 is bonded to the edge of pad 2. In order to facilitate normal connection and improve foot feel, cavity 3 is square and arranged around the sole of foam pad 2. The width of adhesive layer 4 is 1.2 cm. The front end of foam pad 2 A resin layer 5 is embedded and bonded, and an insole layer 6 is bonded to the top of the foam pad 2;

[0052] A shock-absorbing chamber 7 is provided at the rear heel position of the TPU sole matrix 1, and the interior of the shock-absorbing chamber 7 is filled with elastic cotton 8, and a plurality of TPU foamed particles 10 are embedded in the sole of the TPU sole matrix 1;

[0053] The heel of the TPU sole matrix 1 is provided with a wear-resista...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com