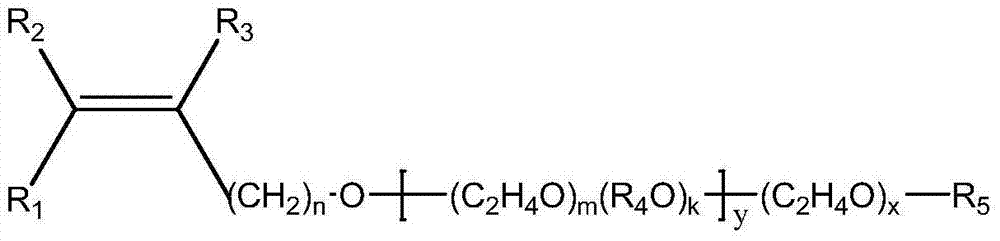

Block polyether, air entrained type polycarboxylate water reducing agent prepared by block polyether and preparation method thereof

A technology of block polyether and water reducer, which is applied in the field of air-entraining polycarboxylate water reducer, which can solve the problems of concrete appearance and performance impact, difficulty in complete polymerization, floating and delamination, etc., to ensure strength and crack resistance The effect of improving performance, improving gas content, and excellent working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

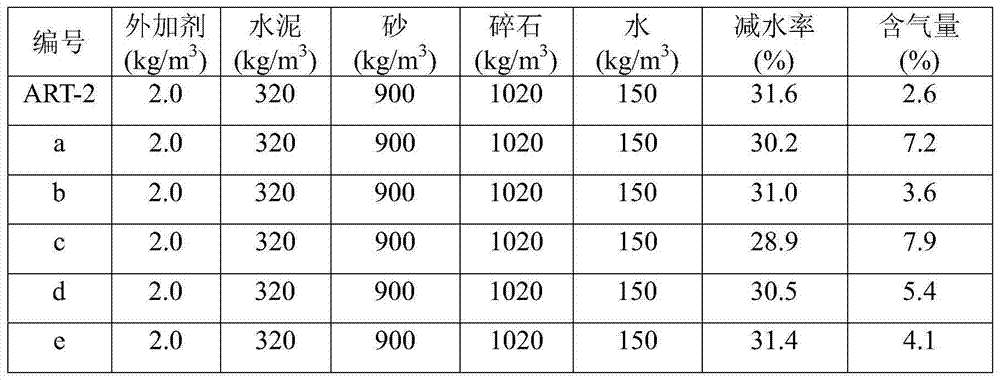

Embodiment 1

[0045] Preparation of block polyethers

[0046] Add 3.0g of methallyl alcohol and 0.02g of basic catalyst KOH into the reactor, replace the inside of the reactor with nitrogen three times, empty the nitrogen in the reactor until the pressure inside the reactor is 0.02-0.05MPa, and raise the temperature in the reactor to to 120°C. Maintain the temperature, add 25.0g EO (ethylene oxide) continuously within 2h (hour), and age for 20-30min. Raise the temperature to 150°C, continuously add 21.6g PO (propylene oxide) within 1.5h, maintain the reaction temperature, and age for 40 to 60 minutes. After cooling down to 120°C, add 12.8g of ethylene oxide continuously within 1h, maintain the reaction temperature, and age for 40-60min. After aging, cool down to 60°C, add acetic acid to neutralize, and discharge. The obtained block polyether has a weight average molecular weight of 1400 and a double bond retention rate of 91.05%. (m+k)y+x=29, y=1, x=7.

[0047] Preparation of air-entrai...

Embodiment 2

[0051] Preparation of block polyethers

[0052] Add 3.45g prenyl alcohol and 0.03g basic catalyst KOH into the reactor, carry out 3 nitrogen replacements in the reactor, empty the nitrogen in the reactor until the pressure in the reactor is 0.02-0.05MPa, and raise the temperature in the reactor to 120°C. Maintain the reaction temperature, add 17.62g EO continuously within 1.0h, and age for 20-30min. Raise the temperature to 150°C, add 11.62g PO continuously within 1h, maintain the reaction temperature, and age for 40-60min. After cooling down to 120°C, 17.62g of EO was continuously added within 1h, and the temperature was raised to 150°C, and 11.62g of PO was continuously added within 1h to maintain the reaction temperature and aged for 40-60min. After aging, cool down to 60°C, add acetic acid to neutralize, and discharge. The obtained block polyether has a weight average molecular weight of 1550 and a double bond retention rate of 89.87%. m+k=15, y=2, x=0.

[0053] Prepa...

Embodiment 3

[0057] Preparation of block polyethers

[0058] Add 2.32g of allyl alcohol and 0.02g of basic catalyst KOH into the reactor, replace the reactor with nitrogen 3 times, empty the nitrogen in the reactor until the pressure in the reactor is 0.02-0.05MPa, and raise the temperature in the reactor to to 120°C. Maintain the reaction temperature, add 21.14g EO continuously within 2h, and age for 20-30min. Raise the temperature to 150°C, add 13.94g PO continuously within 1.5h, maintain the reaction temperature, and age for 40-60min. After cooling down to 120°C, add 21.14g of EO continuously within 2h, maintain the reaction temperature, and age for 40-60min, then raise the temperature to 150°C, add 13.94g PO continuously within 1.5h, maintain the reaction temperature, and age for 40-60min. After cooling down to 120°C, add 21.14g of EO continuously within 2h, maintain the reaction temperature, and age for 40-60min, then raise the temperature to 150°C, add 13.94g PO continuously within...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com