Lower multi-layer assembly type heat insulation and energy saving building

A prefabricated and architectural technology, applied in construction, building components, industrial buildings, etc., to achieve the effects of speeding up construction, saving structural earthquake resistance, reducing environmental pollution and material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to facilitate the understanding of the technical solution and operation method of the present invention, the present invention will be further described through the following specific embodiments in conjunction with the accompanying drawings.

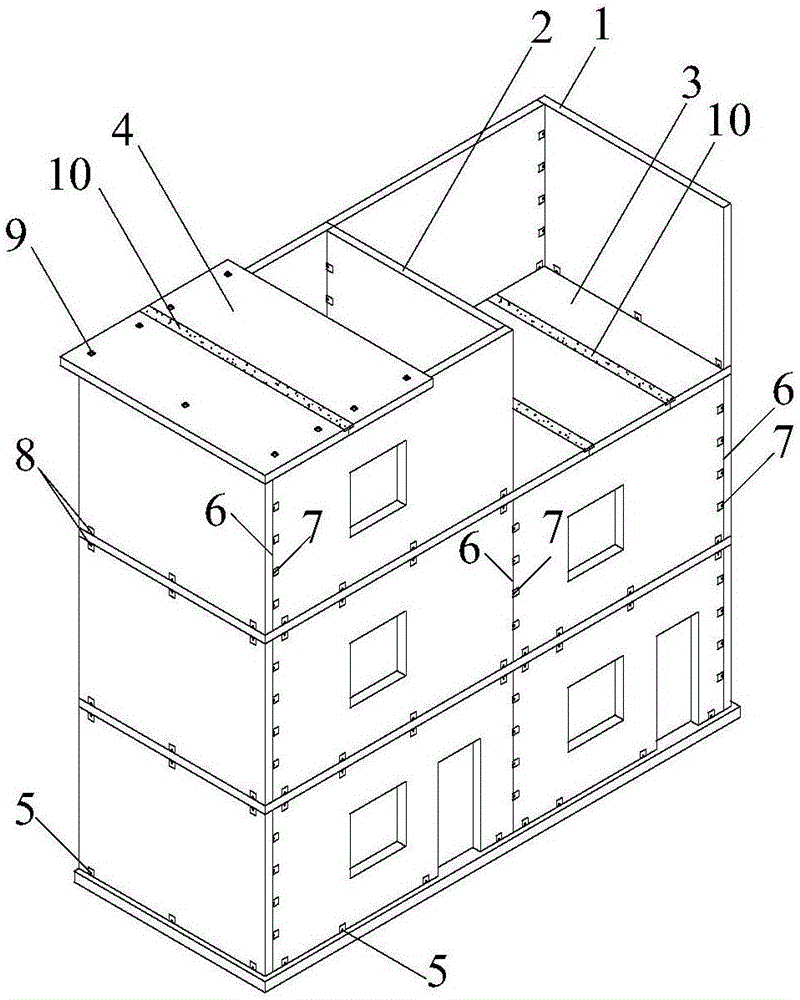

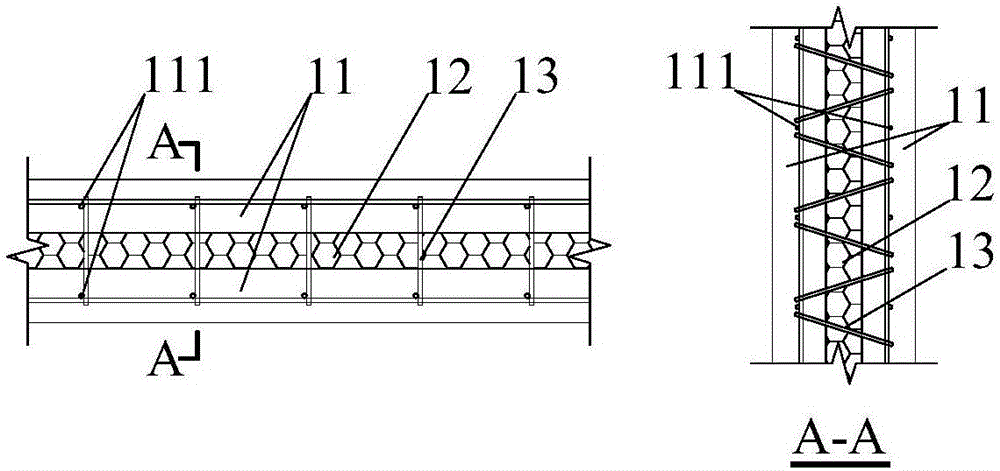

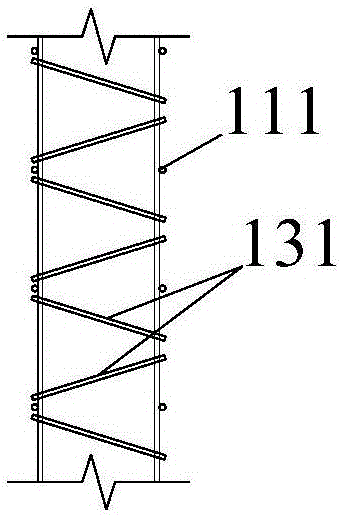

[0028] According to a specific embodiment of the present invention, the main structure of the low-level prefabricated thermal insulation and energy-saving building includes walls, floors and roofs, all of which are prefabricated panels (including prefabricated exterior wall panels 1, prefabricated interior wall panels 2 , prefabricated floor slab 3 and prefabricated roof panel 4). The prefabricated panel adopts a sandwich structure with an insulating layer, and can be designed as a whole large panel or a strip panel according to the production, transportation and construction conditions. The prefabricated wall panels are connected to the foundation through vertical connection devices 5 uniformly arranged along the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com