Transverse self-heat-preservation energy-saving concrete block

A technology of self-insulation and concrete blocks, which is applied in the direction of building components, buildings, building structures, etc., and can solve problems such as blind joints, difficulty in timely drainage of rainwater from walls, and non-compliance with code requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0015] The specific implementation, non-limiting examples are as follows:

Embodiment

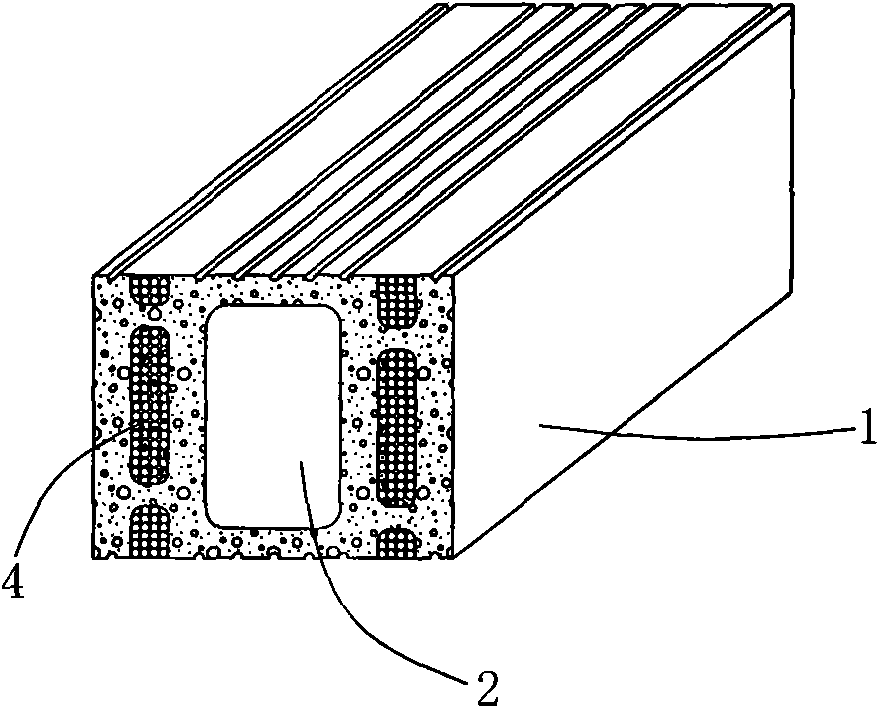

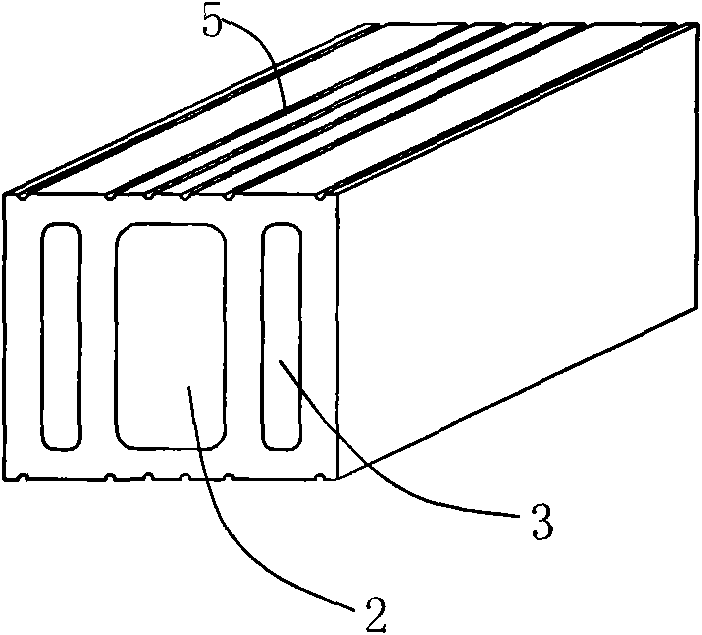

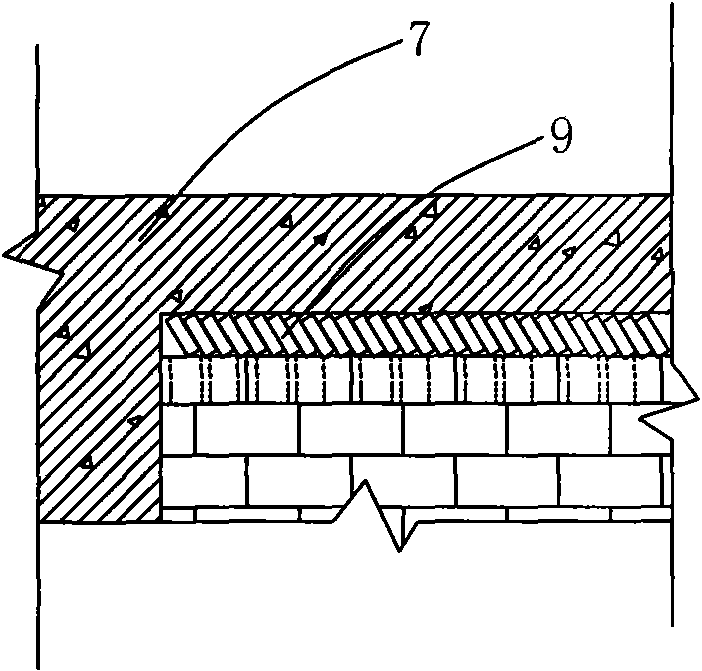

[0016] Example: Combine figure 1 , 2 , the block of the present invention, the length direction of the block body 1 is arranged according to the length direction of the wall, and a through hole 2 passing through the block body is opened in the middle of the block along its length direction, and on both sides of the through hole There are insulation holes 3 for filling the insulation material 4 along the length direction of the block, and a plurality of parallel grouting grooves 5 are arranged on the top and bottom surfaces of the block, and the grouting grooves are arranged along the length direction of the block.

[0017] combine figure 2 , the heat preservation hole 3 is distributed on both sides of the through hole 2, and the heat preservation hole on each side of the through hole is an integral structure; combined figure 1 , the heat preservation holes are distributed on both sides of the through hole, and the heat preservation holes on at least one side of the through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com