Fabricated light-weight interior partition wall joint structure and construction method thereof

An internal partition wall, prefabricated technology, applied in building structures, walls, building components, etc., can solve the problems of complex construction procedures, large amount of engineering, long construction period, etc., and achieve a shortened construction period, low cost, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

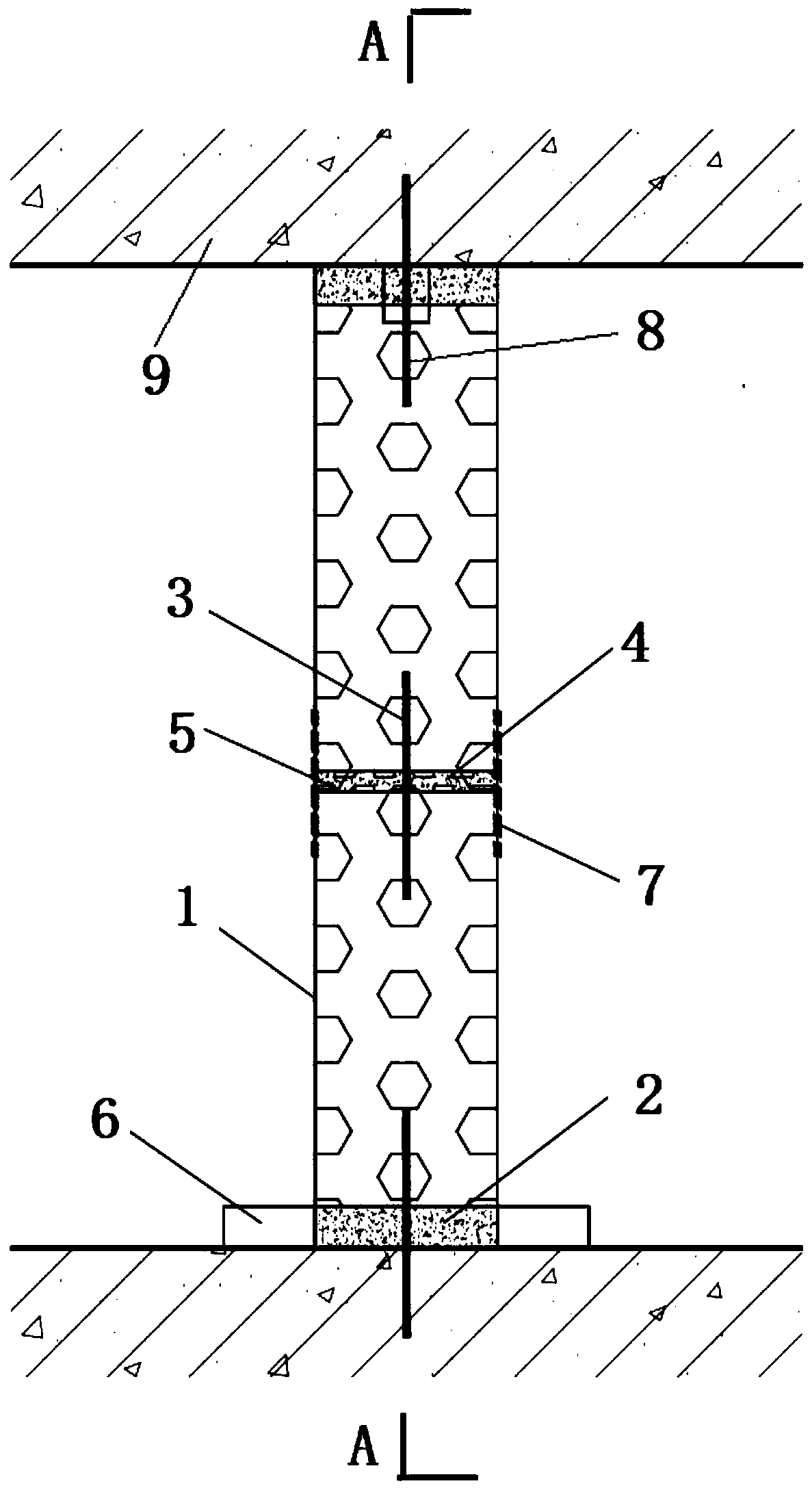

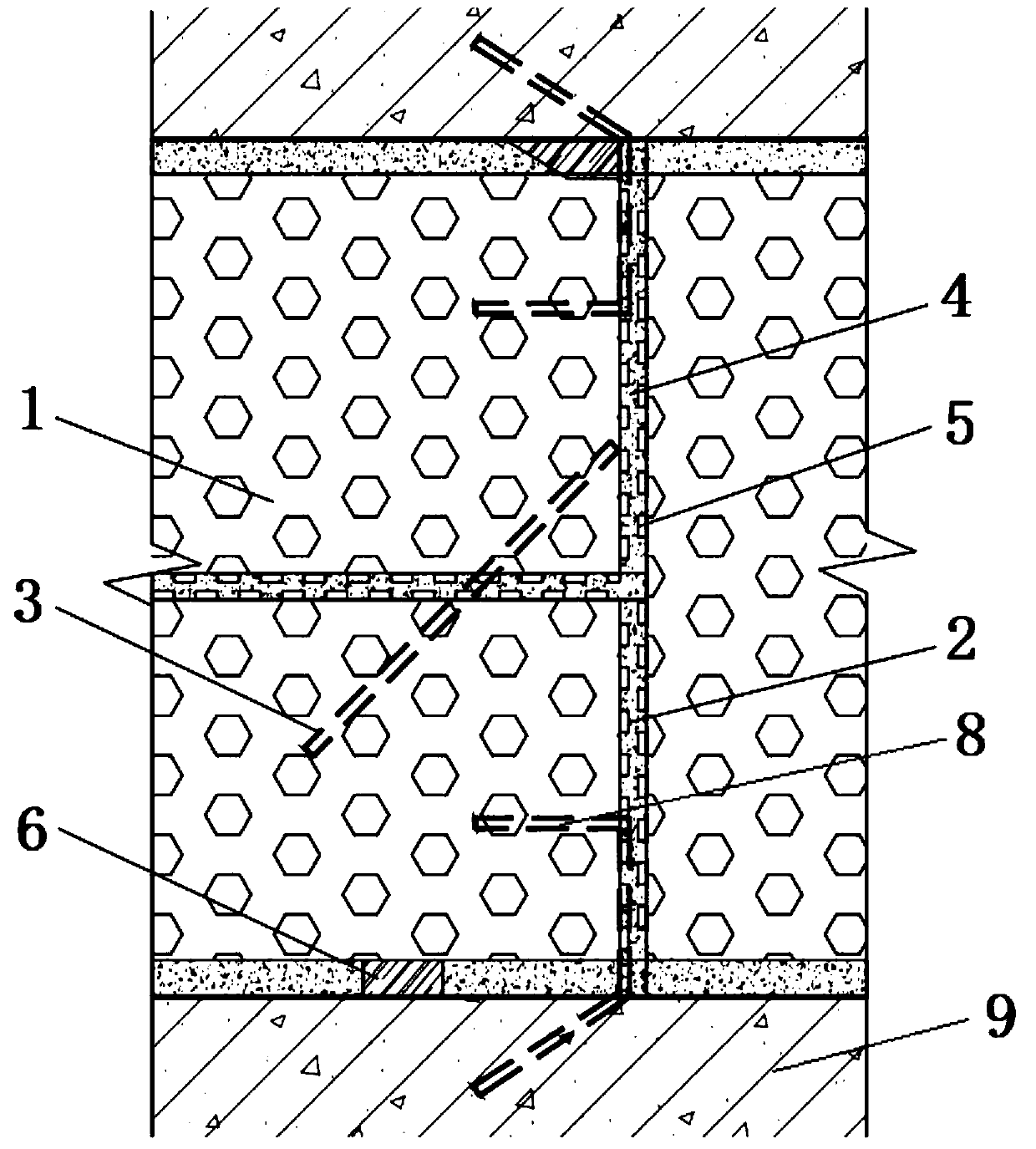

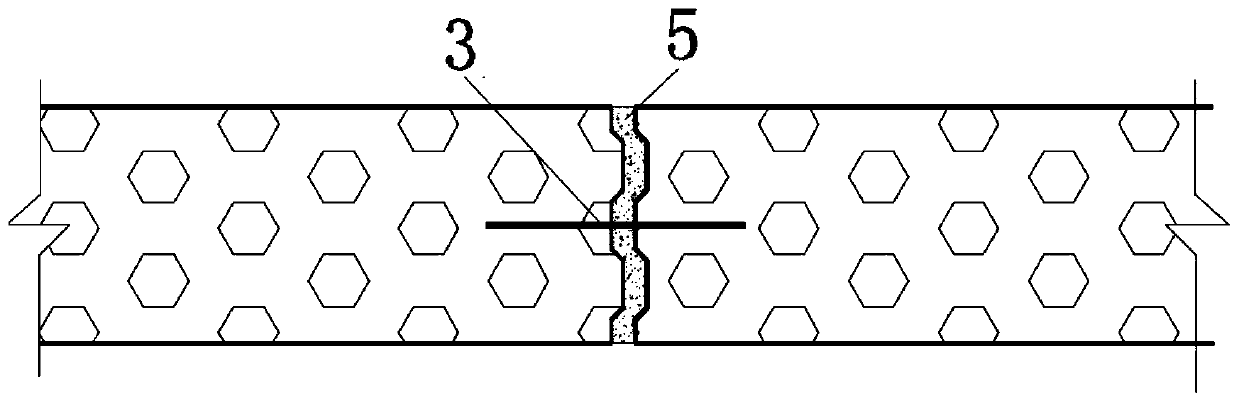

[0018] Embodiments of the invention: see Figure 1~3 , a prefabricated lightweight interior partition wall assembly node structure, including a concrete floor or beam 9 and two or more lightweight interior partition wall prefabricated panels 1, prefabricated between the concrete floor or beam 9 and the lightweight interior partition wall A fiber cement wedge plug 6 is embedded between the slabs 1, and a "7"-shaped anchoring steel bar 8 is implanted between the concrete floor or beam 9 and the lightweight inner partition wall prefabricated slab 1, and between the concrete floor or beam 9 and the light The gaps between the prefabricated panels 1 of the inner partition wall are filled with adhesive mortar 2; the inner partition wall joints 4 between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com