Delayed coagulation Portland cement for road base layer and production method

A technology of retarded silicate and road base, applied in cement production, etc., can solve problems such as unreasonable proportion of ingredients, inability to be used as road base, and inconspicuous social benefits, so as to achieve obvious social benefits, increase popularity and reputation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

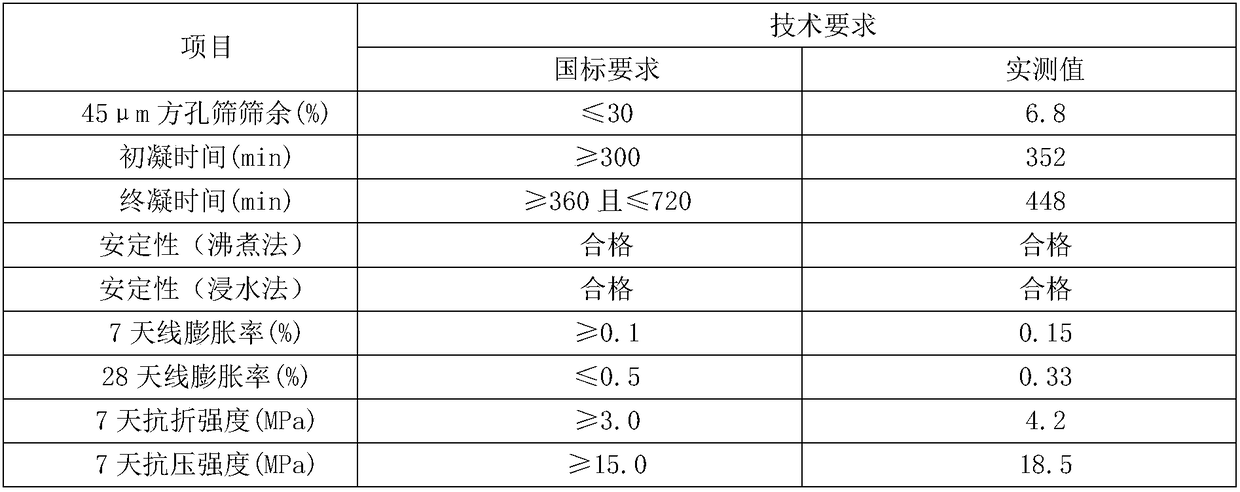

Embodiment 1

[0024] A kind of slow-setting Portland cement for road base, comprising the following raw materials in mass percentage: 45% of clinker, 11% of desulfurized gypsum, 11% of limestone, 8% of slag, 25% of fly ash, grinding aid (retarding type )0.8%.

[0025] Based on the above raw material ratio, a production method of retarded portland cement for road base is provided, comprising the following steps:

[0026] Step 1: Clinker, desulfurized gypsum, limestone, slag and fly ash are crushed and pre-homogenized, and after grinding, traditional methods are used to prepare raw materials;

[0027] Step 2: preheating and partially decomposing the raw meal in the above steps through a cyclone preheater;

[0028] Step 3: After the raw meal is preheated and pre-decomposed in the cyclone preheater, it enters the next process;

[0029] Step 4: Enter the cement rotary kiln to burn the clinker. In the rotary kiln, the carbonate is further decomposed rapidly and sends a series of solid-phase rea...

Embodiment 2

[0032] A kind of slow-setting Portland cement for road base, comprising the following raw materials in mass percentage: 50% of clinker, 7% of desulfurized gypsum, 7% of limestone, 6% of slag, 30% of fly ash, grinding aid (retarding type )0.8%.

[0033] The production method of this embodiment is the same as that of Embodiment 1, so it will not be repeated.

Embodiment 3

[0035] A kind of slow-setting portland cement for road base, comprising the following raw materials in mass percentage: 55% of clinker, 3% of desulfurized gypsum, 3% of limestone, 4% of slag, 35% of fly ash, grinding aid (retarding type )0.8%.

[0036] The production method of this embodiment is the same as that of the above embodiment, so it will not be described in detail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com