Concrete for dams and preparation method thereof

A technology for concrete and dam, applied in the field of concrete for dam and its preparation, can solve the problems of alkali content regulation, reduce engineering life, affect concrete durability, etc. The effect of alkali-aggregate reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

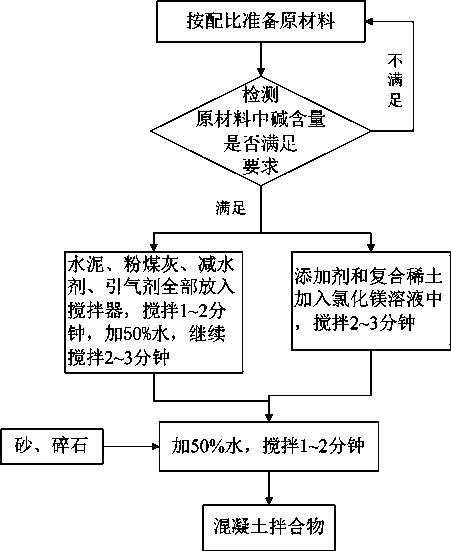

Method used

Image

Examples

Embodiment 1

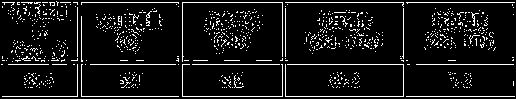

[0030] Example 1: The implementation of the dam concrete, the proportioning of each raw material in the concrete per cubic meter is as follows:

[0031] Sand: 700kg, gravel: 1000kg, water: 90kg, cement: 300kg, fly ash: 100kg, water reducer: 6.0kg, air-entraining agent: 65kg, magnesium chloride solution: 50kg, additive: 3kg, compound rare earth: 30g.

[0032] The mass percentages of the composite rare earth components are: lanthanum: 12%, cerium: 18%, scandium: 19%, yttrium: 9%, samarium: 7%, neodymium: 11%, gadolinium: 7%, praseodymium: 1%, dysprosium : 16%.

[0033] The weight percent components of the additives are: high aluminum powder: 34%, sodium sulfate aqueous solution: 29%, sodium silicate: 37%.

[0034] The sand is medium sand with a fineness modulus Mf3 - The concentration is greater than 250mg / L; the cement is medium-heat Portland cement, the strength grade is not less than 52.5, and the weight content of MgO is 3.0%. It has the characteristics of low alkali con...

Embodiment 2

[0044] Example 2: Concrete for the dam of this embodiment, the proportioning of each raw material in the concrete per cubic meter is as follows: sand: 720kg, crushed stone: 1030kg, water: 100kg, cement: 320kg, fly ash: 110kg, water reducer: 6.3kg, Air-entraining agent: 85kg, magnesium chloride solution: 60kg, additive: 4kg, compound rare earth: 40g.

[0045] The mass percentages of the composite rare earth components are: lanthanum: 15%, cerium: 15%, scandium: 16%, yttrium: 11%, samarium: 8%, neodymium: 13%, gadolinium: 8%, praseodymium: 2%, dysprosium : 12%. The weight percent components of the additives are: high aluminum powder: 37%, sodium sulfate aqueous solution: 27%, sodium silicate: 36%.

[0046] The sand is fine sand with a fineness modulus Mf3 - The concentration is greater than 250mg / L; the cement is medium-heat Portland cement, the strength grade is not less than 52.5, and the weight content of MgO is 3.2%; the fly ash is Class I fly ash, the fineness is less t...

Embodiment 3

[0056] Example 3: Concrete for the dam of this embodiment, the proportioning of each raw material in the concrete per cubic meter is as follows: sand: 750kg, crushed stone: 1050kg, water: 110kg, cement: 350kg, fly ash: 120kg, water reducer: 6.5kg, Air-entraining agent: 95kg, magnesium chloride solution: 70kg, additive: 5kg, compound rare earth: 50g.

[0057] The mass percentages of the composite rare earth components are: lanthanum: 13%, cerium: 16%, scandium: 17%, yttrium: 10%, samarium: 9%, neodymium: 12%, gadolinium: 9%, praseodymium: 3%, dysprosium : 11%.

[0058] The weight percent components of the additives are: high aluminum powder: 34%, sodium sulfate aqueous solution: 27%, sodium silicate: 39%.

[0059] The sand is medium sand with a fineness modulus Mf3 - The concentration is greater than 250mg / L; the cement is medium-heat Portland cement, the strength grade is not less than 52.5, and the weight content of MgO is 3.0%-3.5%; the fly ash is Class I fly ash, the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com