Lego hollow brick forming machine and production method

A forming machine and hollow technology, applied in the direction of forming indenters, etc., can solve the problem of high milling and cutting cost, and achieve the effect of reducing labor input, good product consistency, and increasing height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

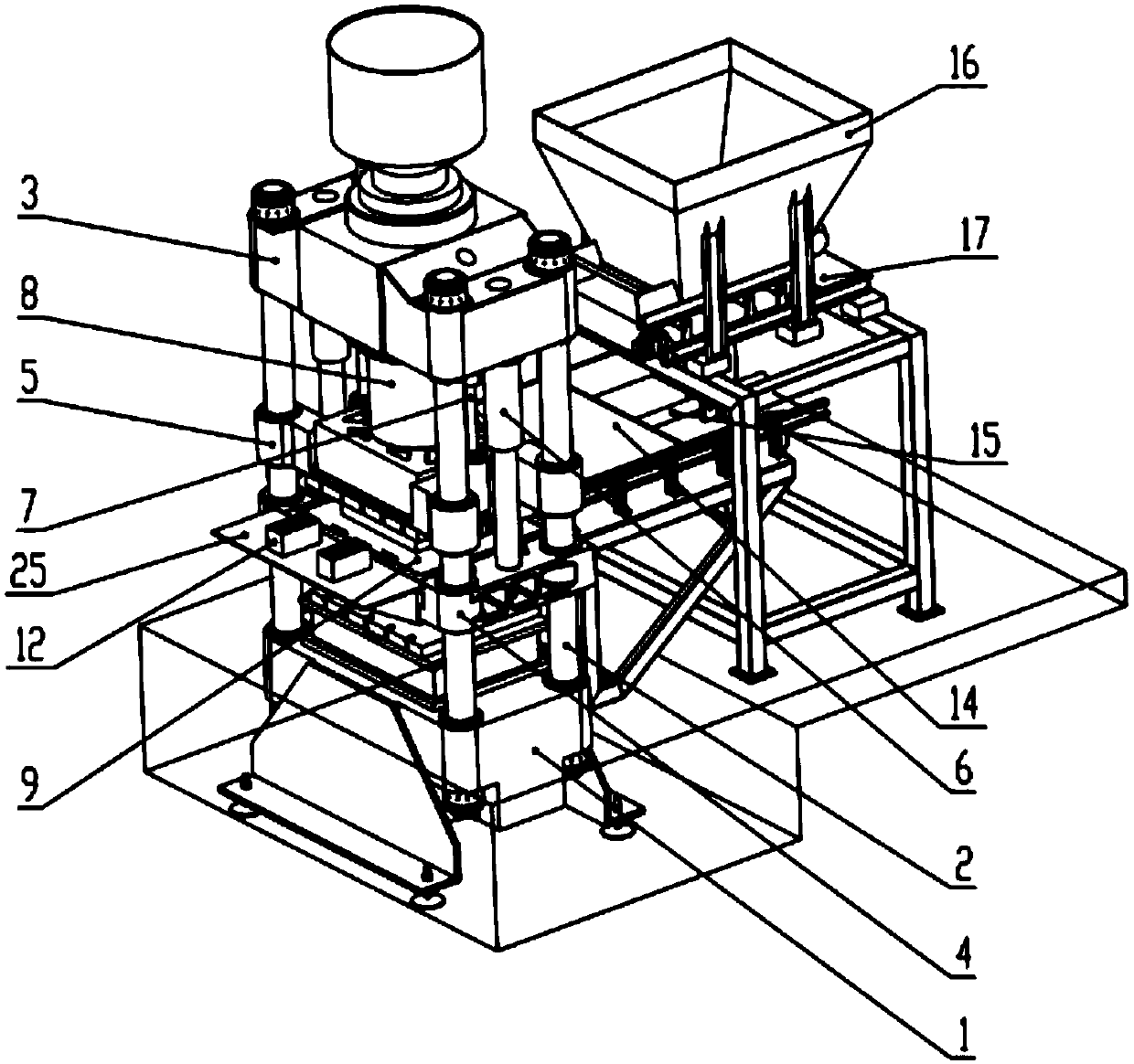

[0021] As shown in the figure, a Lego hollow brick molding machine includes a base platform 1, a hopper 16, a feeding conveyor belt 17, an upper beam 3, a movable beam I5, a movable beam II4, a machine column 2, a main hydraulic cylinder 8, and an upper punch 10 , lower punch 11, groove 9, hydraulic cylinder Ⅳ 20, core tool 18, metal sheet 13, stacking platform 25; the machine column 2 is provided with four mounted on the base platform 1; the movable beam Ⅱ 4 , movable crossbeam I5, upper crossbeam 3 are installed on the described machine column 2 successively from bottom to top; Described upper crossbeam 3 is fixed crossbeam; Described main hydraulic cylinder 8 is installed on the described upper crossbeam 3; Said movable crossbeam I5 is connected with the push rod of the main hydraulic cylinder 8, and can move up and down along the machine c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com