Step face door pocket automatic combination machine with veneer as standard and combination method thereof

A combination machine and veneer technology, applied in wood processing equipment, manufacturing tools, etc., can solve the problems of low combination success rate, bending, and affecting process quality, so as to improve the combination efficiency, reduce height error, and reduce the bending of finished products. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

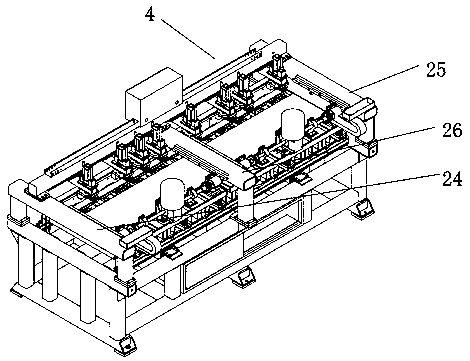

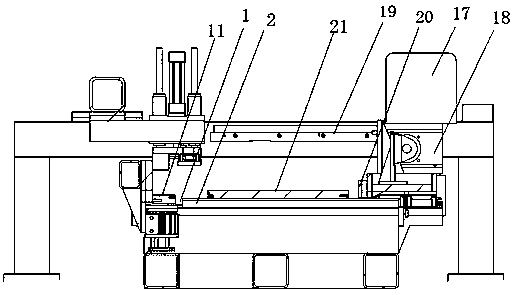

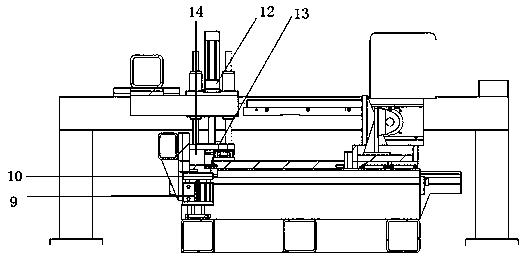

[0039] Such as Figure 1 to Figure 6 As shown, a step face door cover automatic assembly machine based on the finish includes a machine base 4, and also includes a machine seat installed on the top of the machine base 4,

[0040] The first workpiece groove 1, the main sleeve 11 is placed in the first workpiece groove 1;

[0041] The second workpiece platform 2, the second workpiece platform 2 is located at the side of the first workpiece groove 1, and is equal to the length of the first workpiece groove 1, and a secondary sleeve 21 is placed on the second workpiece platform 2;

[0042] The pushing module is located on the opposite side of the second workpiece platform 2 and the first workpiece groove 1, and is used to push the secondary sleeve 21 to the main sleeve 11, so that the secondary sleeve 21 and the main sleeve 11 are pressed together;

[0043]The pressing module is installed above the first workpiece groove 1, and includes a movable pressing piece that can extend to...

Embodiment 2

[0053] Such as figure 2 , image 3 with Figure 4 As shown, a combination method of an automatic combination machine for stepped door casings based on the finish, including the following steps:

[0054] Step 1, adjust the height of the feed roller 5 to make it higher than the support platform 3, and adjust the height of the ruler to make it higher than the height of the feed roller 5, put the main sleeve 11 into the first workpiece groove 1, and the upper surface of the main sleeve 11 As a decorative surface, the main cover 11 is in conflict with the ruler through the feed roller 5, and the secondary cover 21 is placed on the second workpiece platform 2, and the upper surface of the secondary cover 21 is a decorative surface, and the secondary cover 21 is made by the feed roller 5. Contradicting with the ruler, after completing the positioning of the main sleeve 11 and the auxiliary sleeve 21, the feed roller 5 is lowered to a height lower than the lifting plate 10. At this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com