High polymer quaternary phosphonium salt antibacterial material and preparation method thereof

A technology of antibacterial materials and quaternary phosphonium salts, which is applied in the field of polymer antibacterial materials and its preparation, can solve the problems of limited application fields, poor heat resistance of antibacterial polymer materials, easy migration and loss of antibacterial agents, and achieve broad application fields , long-lasting antibacterial function, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

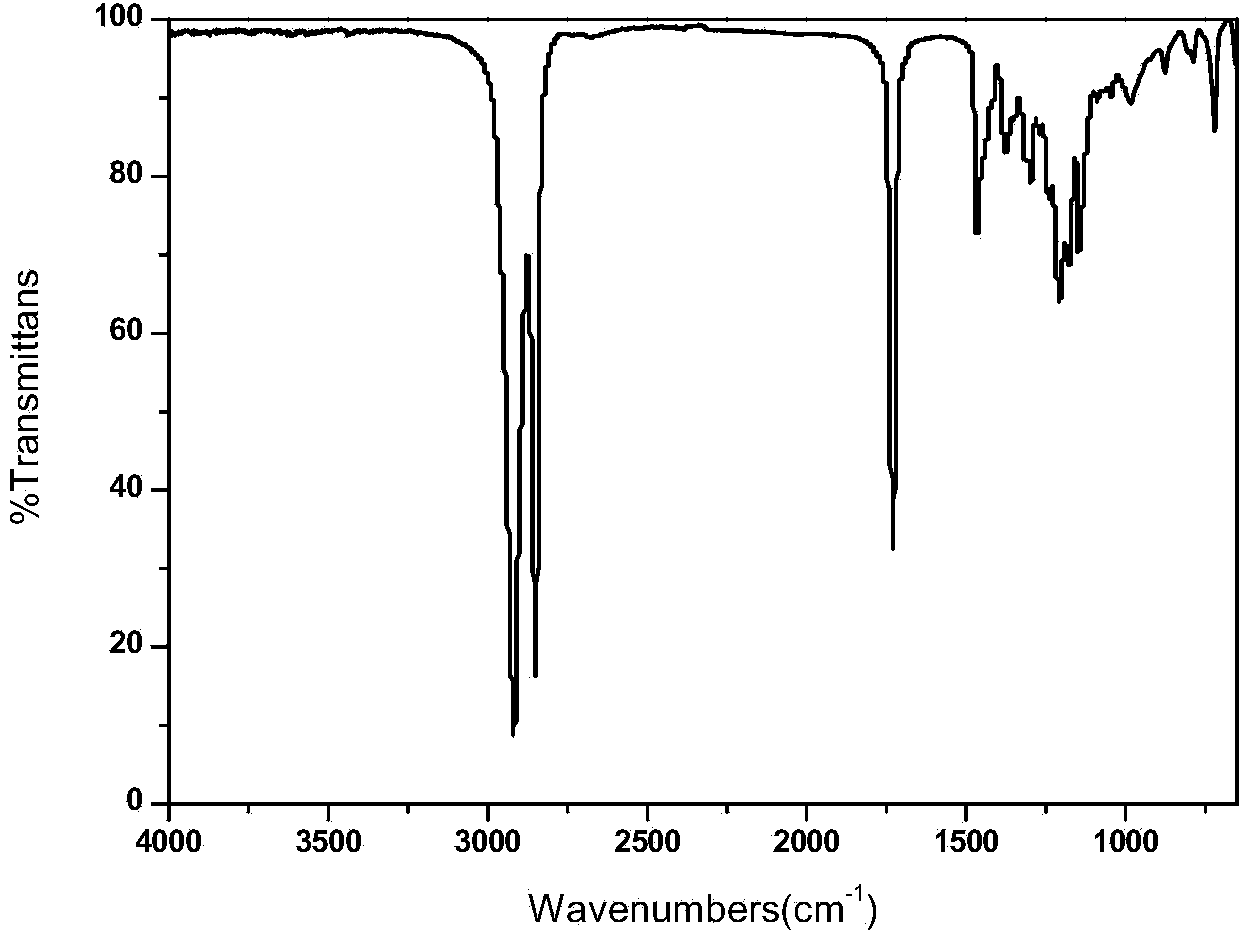

Embodiment 1

[0031] Polymer quaternary phosphonium salt antibacterial material of the present invention, its specific structural formula is:

[0032]

[0033]The preparation method of above-mentioned polymer quaternary phosphonium salt antibacterial material of the present invention, its detailed steps are as follows:

[0034] a. Using ethylene-vinyl alcohol copolymer EVOH (the mass fraction of vinyl alcohol is 16.6%) and 4-chlorobutyryl chloride as basic raw materials, first add 53.0g EVOH into a 500mL four-necked flask, then add 320mL xylene to dissolve, Stir and raise the temperature to 85°C. After the EVOH is completely dissolved, add 28.2g of 4-chlorobutyryl chloride dropwise. After the dropwise addition, react at a constant temperature of 85°C for 9 hours; after the reaction is completed, slowly pour the reaction solution into acetone for precipitation , the volume of acetone used is 5 times the volume of the reaction solution, and the obtained precipitated solution is placed at 2...

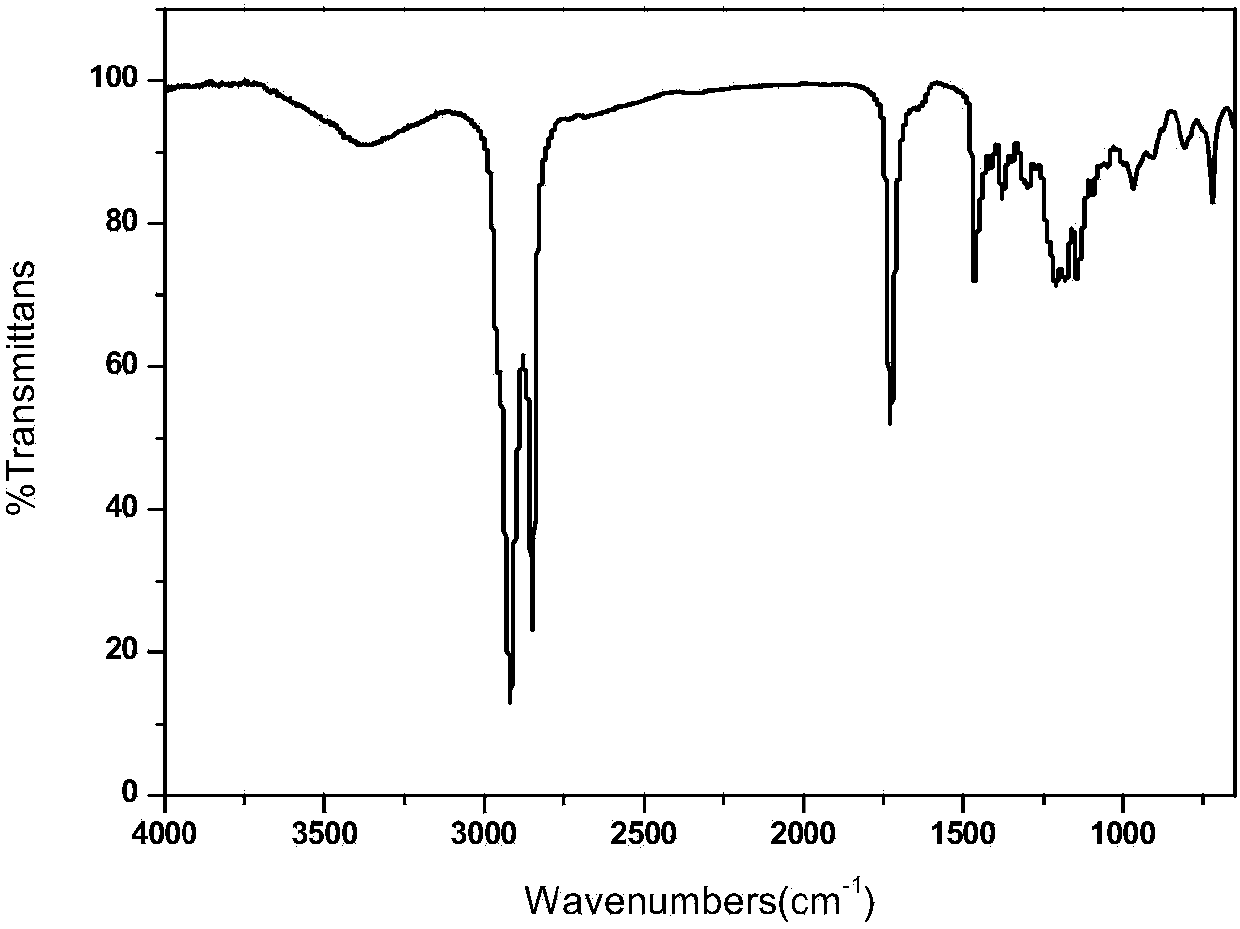

Embodiment 2

[0040] The polymer quaternary phosphonium salt antibacterial material of the present invention has the same specific structural formula as in Example 1.

[0041] The preparation method of above-mentioned polymer quaternary phosphonium salt antibacterial material of the present invention, its detailed steps are as follows:

[0042] a. Using ethylene-vinyl alcohol copolymer EVOH (the mass fraction of vinyl alcohol is 16.6%) and 4-chlorobutyryl chloride as basic raw materials, first add 53.0g EVOH into a 500mL four-necked flask, then add 320mL xylene to dissolve, Stir and raise the temperature to 85°C. After the EVOH is completely dissolved, add 36.7g of 4-chlorobutyryl chloride dropwise. After the dropwise addition, react at a constant temperature at 85°C for 9 hours; after the reaction, slowly pour the reaction solution into acetone for precipitation , the volume of acetone used is 3 times the volume of the reaction solution, and the obtained precipitated solution is placed at ...

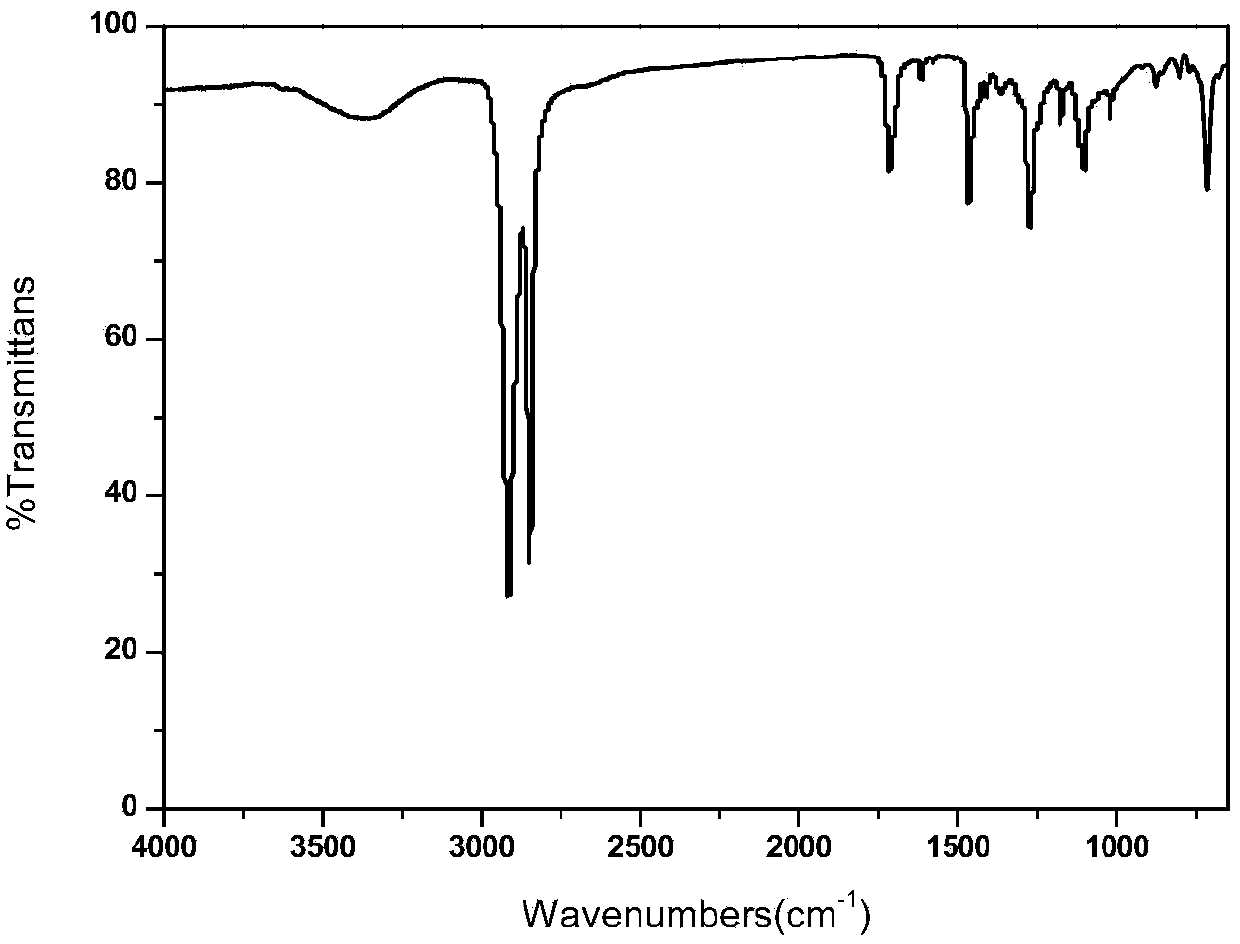

Embodiment 3

[0045] The polymer quaternary phosphonium salt antibacterial material of the present invention has the same specific structural formula as in Example 1.

[0046] The preparation method of above-mentioned polymer quaternary phosphonium salt antibacterial material of the present invention, its detailed steps are as follows:

[0047] a. Using ethylene-vinyl alcohol copolymer EVOH (the mass fraction of vinyl alcohol is 16.6%) and 4-chlorobutyryl chloride as basic raw materials, first add 53.0g EVOH into a 500mL four-necked flask, then add 320mL xylene to dissolve, Stir and raise the temperature to 85°C. After the EVOH is completely dissolved, add 36.7g of 4-chlorobutyryl chloride dropwise. After the dropwise addition, react at a constant temperature at 85°C for 9 hours; after the reaction, slowly pour the reaction solution into acetone for precipitation , the volume of acetone used is 8 times the volume of the reaction solution, and the resulting precipitated solution is placed at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com