Carbon fiber molding material, molding material, and carbon fiber-strengthening composite material

A carbon fiber and forming blank technology, which is applied in the direction of fiber type, fiber treatment, thin material treatment, etc., can solve the problem of insufficient improvement of the adhesion between carbon fiber and matrix resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

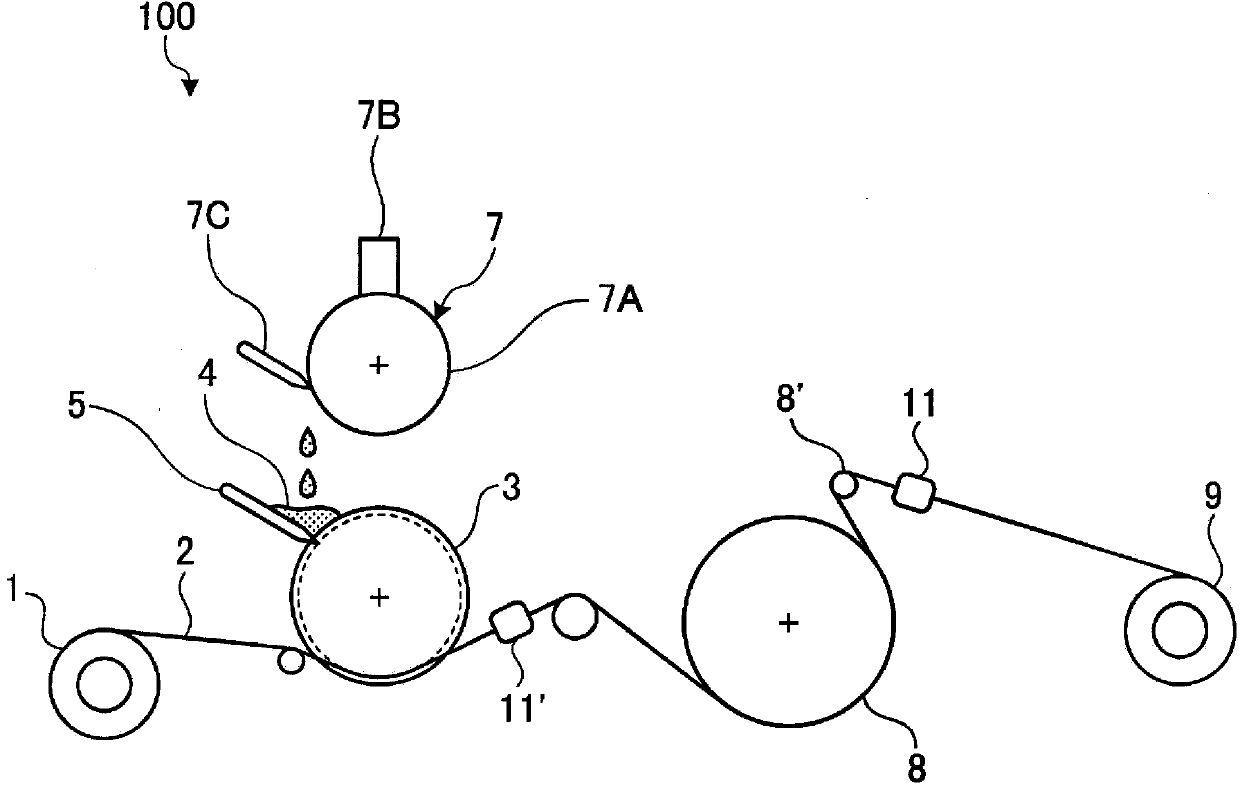

Image

Examples

reference example 1

[0498] (Reference example 1) Manufacturing method of prepreg A

[0499] The epoxy resin compositions in the compounding proportions described in Tables 1 to 4 were coated on a release paper using a reverse roll coater to prepare a resin film.

[0500] The carbon fiber bundles coated with the sizing agent are unidirectionally paralleled, clamped from both sides by the above-mentioned resin film, and heated and pressed to impregnate the resin to obtain a carbon fiber with a weight per unit area of 190g / m 2 A carbon fiber molding material (Z) which is a unidirectional prepreg having a carbon fiber content of 65% by mass.

[0501] The unidirectional prepreg is cut out, laminated with a predetermined configuration, and heated and cured in an autoclave (heating rate 1.5°C / min, pressure of 0.59MPa, molding at a temperature of 180°C for 2 hours) to produce a laminated board .

reference example 2

[0502] (Reference example 2) Manufacturing method of prepreg B

[0503] For the epoxy resin composition in Table 5, mix ingredients other than epoxy-modified polyamide particles to make a matrix resin composition, and use a reverse roll coater to coat it on a release paper to make a weight per unit area of 31 g / m 2 resin film (primary resin film).

[0504] The carbon fiber bundle coated with the sizing agent is unidirectionally paralleled, clamped from both sides by a resin film, heated and pressed to impregnate the resin, and the weight per unit area of the carbon fiber is 190g / m 2 primary prepreg.

[0505] Next, the thermosetting resin composition containing epoxy-modified polyamide particles was coated on the mold release surface using a reverse roll coater so that the composition of the epoxy resin composition in the prepreg was as shown in Table 5. The weight per unit area of resin made on paper is 21g / m 2 resin film (secondary resin film). By laminating the sec...

reference example 3

[0507] (Reference example 3) Manufacturing method of prepreg C

[0508] The epoxy resin composition of the compounding ratio shown in Table 6 was coated on the release paper using the reverse roll coater, and the resin film was produced.

[0509] The carbon fiber bundle coated with the sizing agent is unidirectionally paralleled, clamped by the above resin film from both sides, heated and pressed to impregnate the resin, and the carbon fiber has a weight per unit area of 125g / m 2 A carbon fiber molding material (Z) which is a unidirectional prepreg having a carbon fiber content of 76% by mass.

[0510] The unidirectional prepregs were cut out, laminated with a predetermined configuration, and heated and cured using an autoclave (heating rate 1.5°C / min, pressure of 0.59MPa, molding at a temperature of 135°C for 2 hours) to produce a laminated board.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com