Impact-modified polycarbonate compositions having a good combination of natural color, hydrolytic stability and melt stability

a technology of hydrolytic stability and composition, which is applied in the field of polycarbonate compositions, can solve the problems of undesirable discoloration of molding compositions and impaired processing stability, and achieve the effects of high hydrolytic stability, excellent processing stability, and efficient and advantageous to the environmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

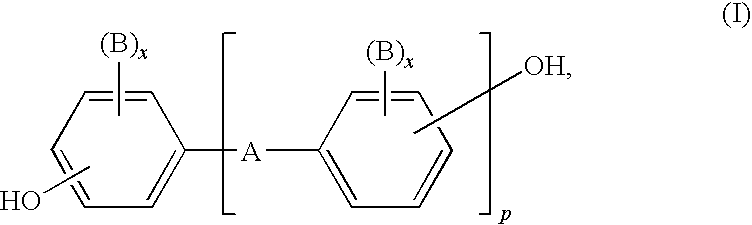

Component A

[0176]A.1: Linear polycarbonate based on bisphenol A having a weight-average molecular weight Mw of 27,500 g / mol (determined by GPC in CH2Cl2 at 25° C.).[0177]A.2: Linear polycarbonate based on bisphenol A having a weight-average molecular weight Mw of 28,500 g / mol (determined by GPC in CH2Cl2 at 25° C.).

Component B

[0178]Emulsion Graft Polymers of Type B

[0179]All parts by weight in the examples of graft polymers below are so standardized that, in each graft polymer indicated hereinbelow, the sum of the parts by weight of the graft base (polybutadiene) and the parts by weight of the graft monomers (styrene and acrylonitrile) is 100 parts by weight. The amounts of water, emulsifiers, initiators and other auxiliary substances are based on this sum of the parts by weight of the graft base and the graft monomers (=100 parts by weight).

[0180]General Procedure (I):

[0181]1st Step: Preparation of the Rubber Base B2:

[0182]The particulate crosslinked rubber base used for the prepara...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wt. % | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com