Fire-resistant fiber-containing article and method of manufacture

a fiber-containing article and fire-resistant technology, applied in the direction of weaving, other domestic articles, transportation and packaging, etc., can solve the problems of health or safety risks that might occur, agricultural fibers are inherently flammable,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

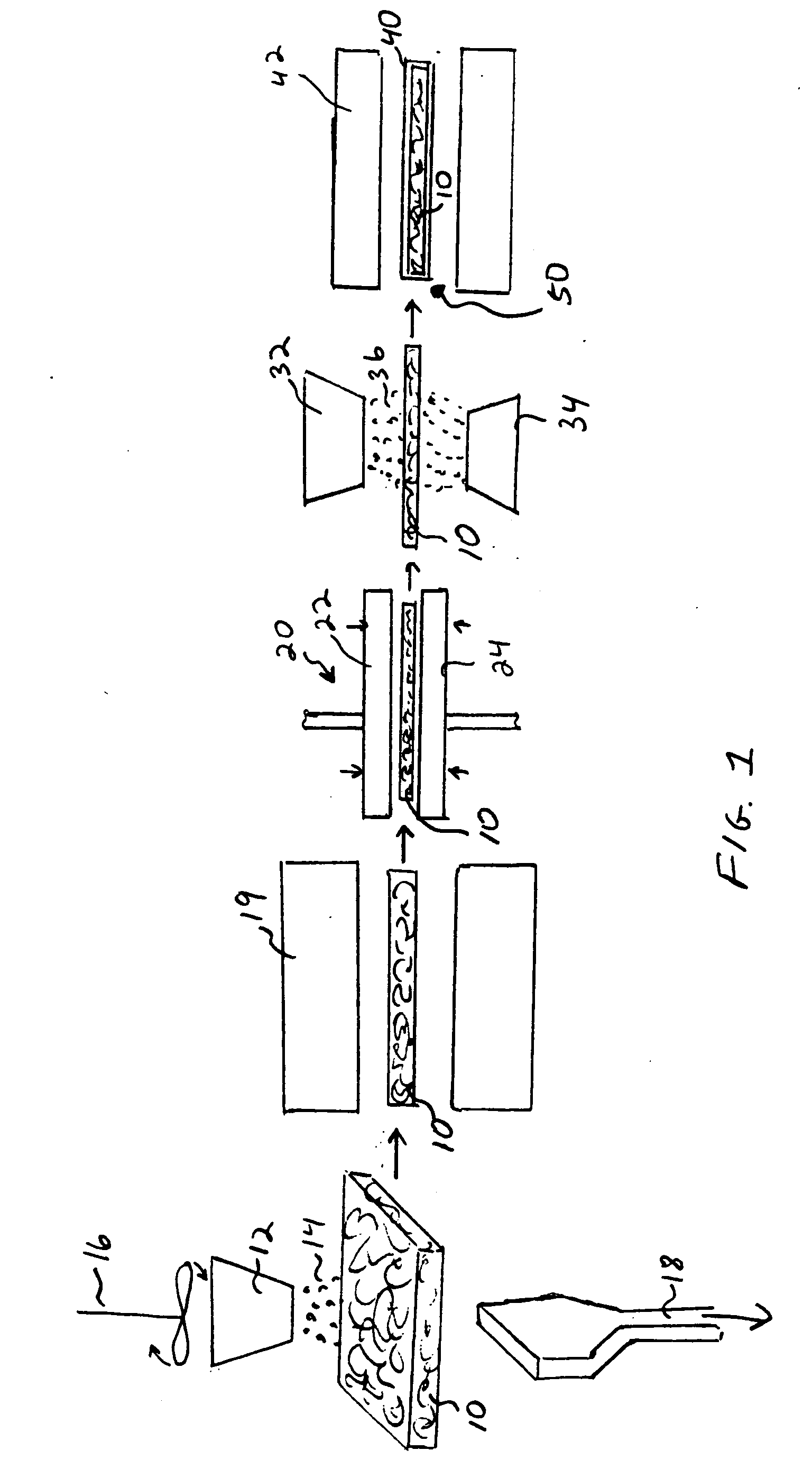

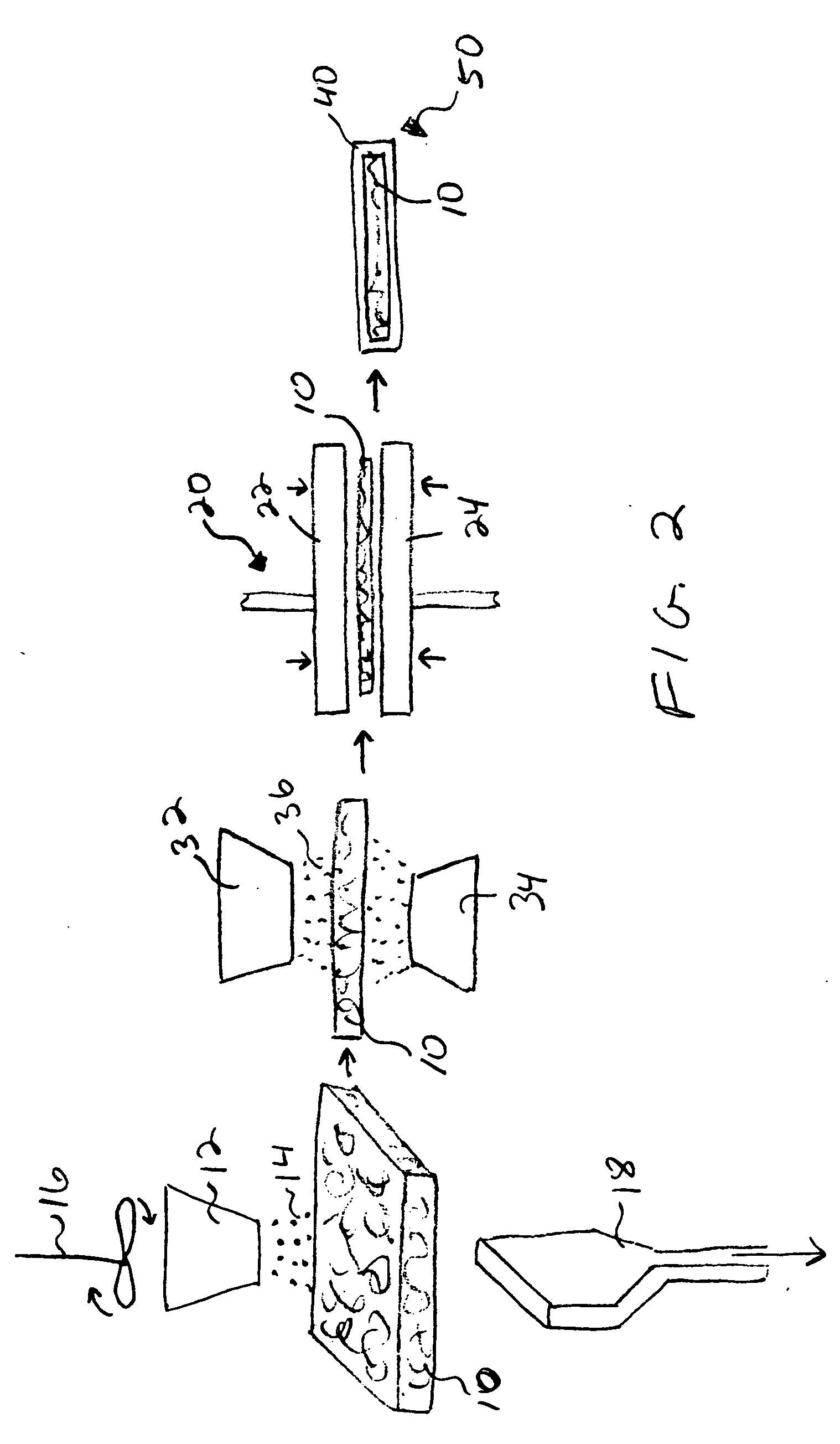

Method used

Image

Examples

example

[0029] A fibrous mass is provided comprising about 20% by weight of polypropylene fibers and about 80% by weight of a natural fiber component, the component containing 50 percent by weight of kenaf fiber and 50 percent by weight of industrial hemp fiber. Sodium polyborate powder is blown through the mass. The mass is heated to a temperature of about 375°-380° F. for about 10-15 minutes in a conventional oven. The mass is compressed to a desired thickness and allowed to cool. The compressed mass is sprayed on all surfaces with a 40% by weight aqueous solution of sodium silicate, at about 1-2 oz. solution per square foot of surface area. The mass is then heated to a temperature of about 390° for about 1-2 minutes to drive off the water and allow the sodium silicate coating to set. The resulting article can be used in the manufacture of a structure having a flame spread index of less than 25 and a smoke generation index of less than 450, which meets the requirement for a Class A rated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight percent | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| thermoplastic | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com