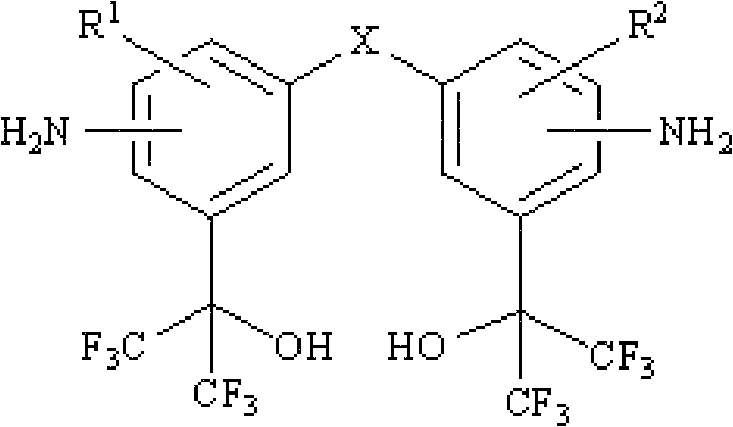

Membrane functional monomer containing hexafluoroisopropanol group and nanofiltration membrane preparation method thereof

A technology of hexafluoroisopropanol and functional monomer, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation and other directions, to achieve the effect of good interception effect, stable performance and strong resistance to the oxidation performance of free chlorine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

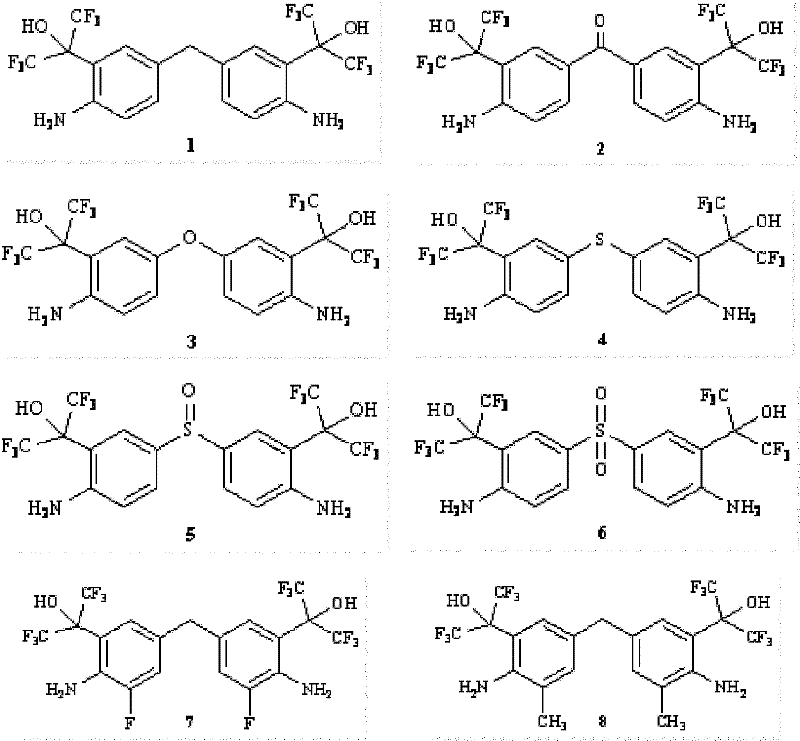

Examples

Embodiment 1

[0031] Monomer 2,2'-bis(1-hydroxy-1-trifluoromethyl-2,2,2-trifluoroethyl)-4,4'-idene containing hexafluoroisopropanol group nanofiltration membrane Synthesis of methyl dianiline:

[0032] To the three-necked flask, add 4,4'-methylene dianiline (1.98g, 10mmol), p-toluenesulfonic acid (0.05g, 0.03mmol) and xylene 8mL, connect a water separator and a condenser, stir and heat up to 100 °C. At 100 °C, hexafluoroacetone trihydrate (3.3 g, 15 mmol) was added dropwise to the three-necked flask with a constant pressure funnel, reacted for 1 hour, then heated to 140 °C, refluxed for 5 hours, and the liquid in the water separator was clarified After the layers are separated, let off the lower liquid. The temperature was lowered to 100°C, and then hexafluoroacetone trihydrate (3.3g, 15mmol) was added dropwise to the three-necked flask for 1 hour; the temperature was raised to 140°C, refluxed for 35h, and after the liquid in the water separator was clarified and layered, let it go The l...

Embodiment 2

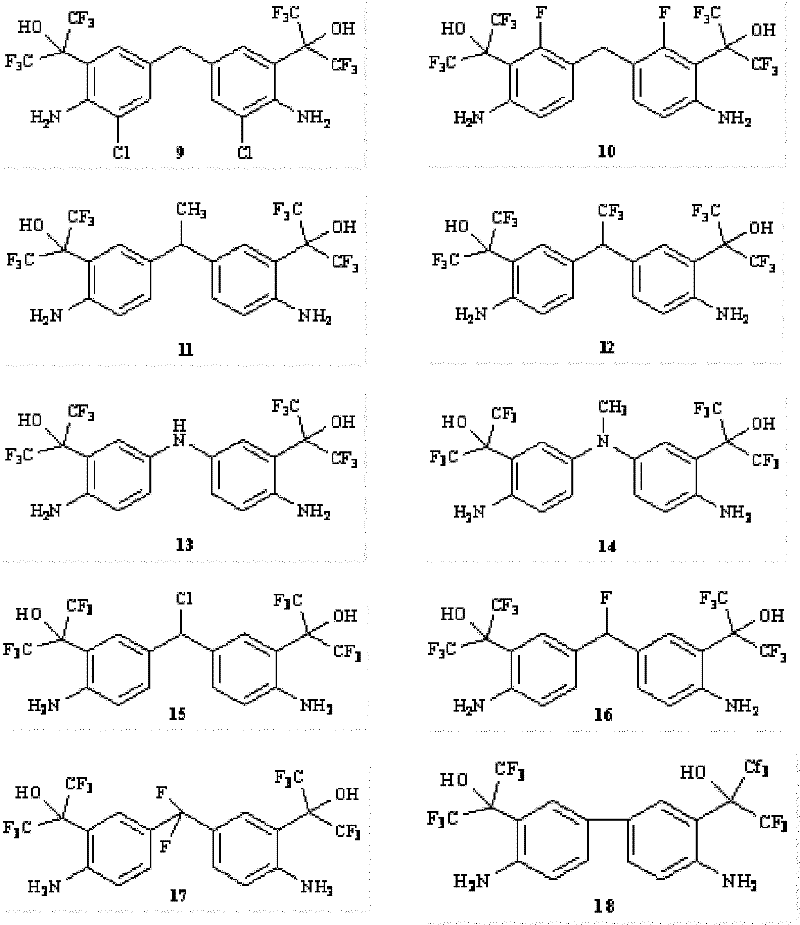

[0035] Preparation of nanofiltration membranes containing hexafluoroisopropanol groups:

[0036] A polyethersulfone flat ultrafiltration membrane with a molecular weight cut-off of 50,000 was used as the base membrane, the base membrane was fixed, and immersed in the aqueous phase solution for 5 minutes; the excess aqueous phase solution on the membrane surface was removed, and a single-sided interfacial polymerization reaction was carried out with the organic phase solution. The reaction time was 10 seconds; dried in air for 3 minutes, and then heat-treated at 80° C. for 5 minutes; rinsed with deionized water for 3 times at room temperature for 20 minutes each to obtain a fluorine-containing nanofiltration membrane.

[0037] The aqueous solution contains 1% fluorine-containing monomer 2,2'-bis(1-hydroxy-1-trifluoromethyl-2,2,2-trifluoroethyl)-4,4'-methylenedianiline (w / v), sodium hydroxide 0.02% (w / v), triethylamine 0.5% (w / v). The oil phase solution solvent was n-hexane and...

Embodiment 3-6

[0039] As in Example 2, as described above, an aqueous solution containing 2,2'-bis(1-hydroxy-1-trifluoromethyl-2,2,2-trifluoroethyl)-4,4'-idene Methyl dianiline 1% (w / v), sodium hydroxide 0.02% (w / v), triethylamine 0.5% (w / v); the organic phase solution contains trimesoyl chloride 0.15% (w / v); Heat treatment at 80°C for 5 minutes; the interfacial polymerization times are 5, 20, 30, and 45 seconds, respectively. The desalination performance was tested under the conditions of 1000 ppm sodium sulfate aqueous solution, operating pressure of 0.6 MPa, and operating temperature of 25 °C.

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com