Additive for flue gas desulfurization and denitration and flue gas desulfurization and denitration method

A desulfurization, denitrification and additive technology, which is applied in the field of flue gas desulfurization and denitrification additives and flue gas desulfurization and denitrification, can solve the problems of cumbersome preparation process and low removal efficiency of highly active absorbent, and achieves simple preparation method, simplified process, convenient production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the additive is not particularly limited in the present invention, and it can be obtained by mixing a tetravalent cerium compound and a calcium-based absorbent.

[0035] The present invention also provides a method for flue gas desulfurization and denitrification, comprising the following steps:

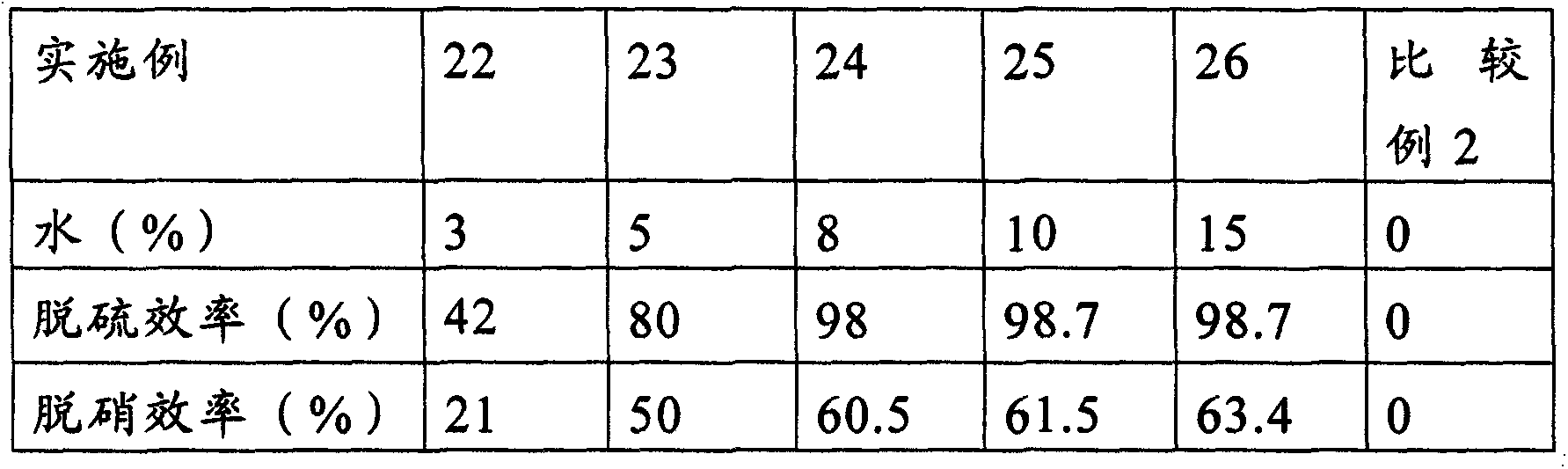

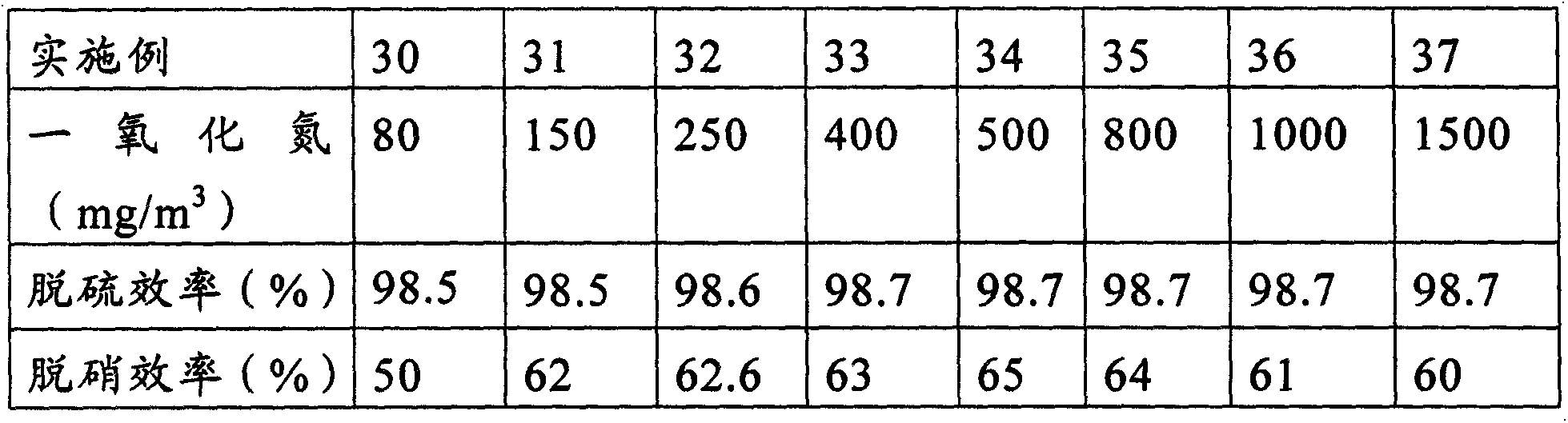

[0036] The raw flue gas, water and the additives described in the above technical scheme are fed into the fluidized bed reactor for reaction to obtain purified flue gas.

[0037] The additive provided by the invention is especially suitable for the current common dry circulating fluidized bed method for desulfurization and denitrification. Specifically, adding the additive described in the invention into a circulating fluidized bed reactor can purify flue gas.

[0038] The present invention has no special limitation on the fluidized bed reactor, and a circulating fluidized bed capable of performing dry desulfurization and denitrification well known to...

Embodiment 1

[0049] Mix 56 g of analytically pure ammonium cerium nitrate with a mass percentage >98.5% and 56 mL of concentrated sulfuric acid with a mass percentage of 98% and a density of 1.84 g / mL, add 100 mL of water and stir well, then dilute the resulting solution to 1 L with water , and fully stirred to prepare a 0.1mol / L cerium source solution. Filter out the insoluble matter in the cerium source solution, add 65 mL of analytically pure ammonia water with a mass concentration of 26% and a density of 0.9 g / mL to the filtrate, stir thoroughly, precipitate, filter, and wash until the washing water does not contain NO 3 - . The above preparation process is carried out under the condition of heating in a water bath at 60°C.

[0050] The obtained precipitate was dissolved in concentrated sulfuric acid under the condition of heating in a water bath at 60°C. After the precipitate was completely dissolved, the heating was stopped, the insoluble matter was filtered off, and the obtained f...

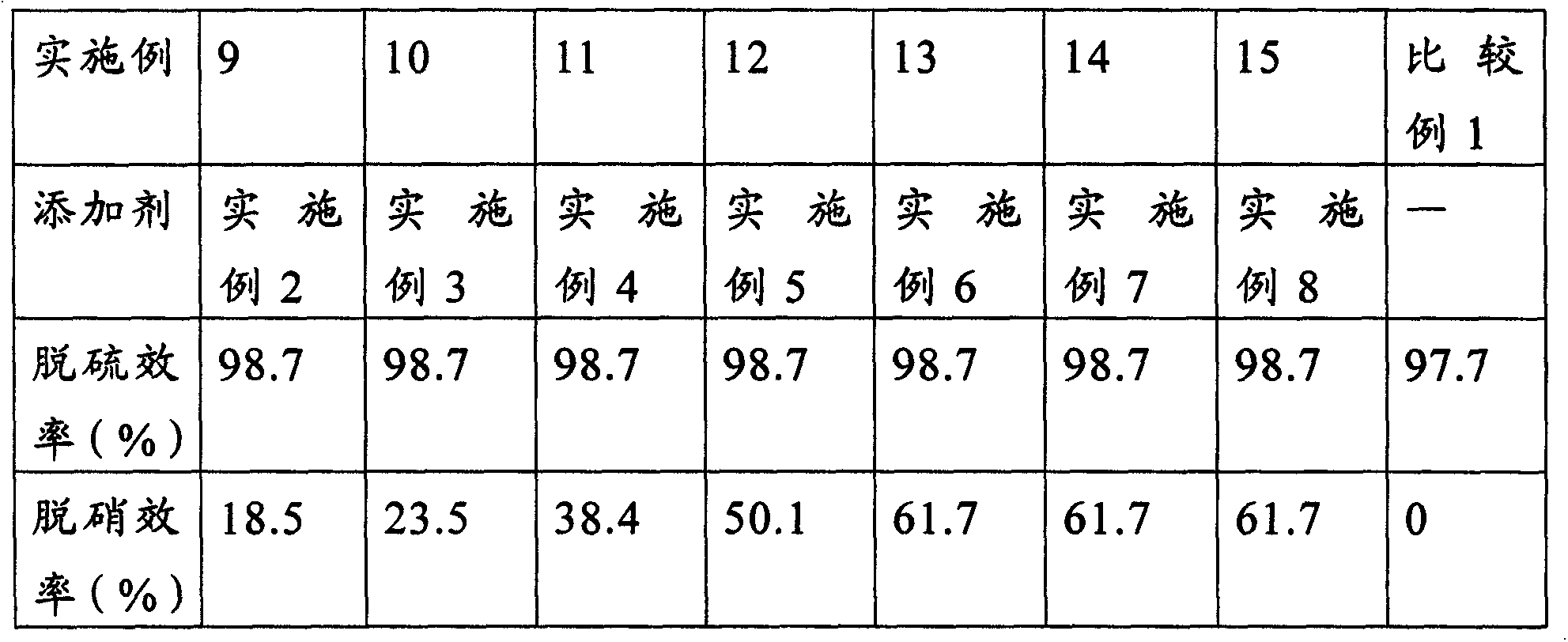

Embodiment 2-8

[0052] Calcium hydroxide and tetravalent cerium compound were mixed according to the weight ratio of raw materials shown in Table 1 to obtain additives respectively.

[0053] The raw material ratio of the additive prepared by the embodiment of the present invention 2-8 in table 1

[0054] Example

[0055] In table 1, the tetravalent cerium compound that embodiment 2,4,6 adopts is the ceric sulfate that embodiment 1 prepares; The tetravalent cerium compound that embodiment 3,5,8 adopts is commercially available cerium oxide; Embodiment 7 The tetravalent cerium compound used is commercially available ceric sulfate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com