Method for adding rare earth to T91 and P91 steel for improving high temperature corrosion resistance

A T91, high temperature resistance technology, applied in the field of adding rare earth to improve high temperature corrosion resistance, can solve the problems of practical application limitations, difficult implementation of the inner wall of the pipeline, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: raw material: rare earth: yttrium oxide (Y 2 o 3 ) Purity ≥ 99.00%, average particle size 15nm; T91 steel pipe.

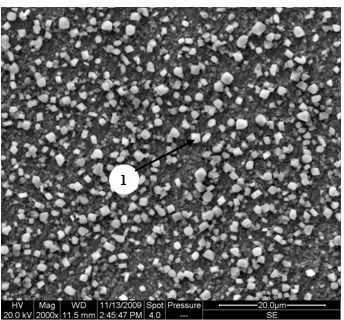

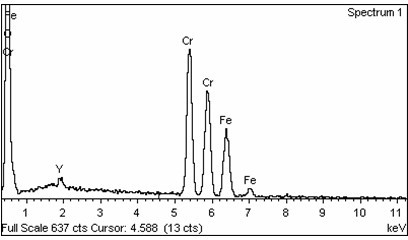

[0018] The required T91 or P91 steel is baked in a protective atmosphere and put into an induction furnace for smelting. After the temperature rises to 1600°C, rare earth Y is added under the protection of argon. 2 o 3 , stirring, standing, pouring, and cooling to obtain T91 and P91 steels containing rare earths. After the modified sample was oxidized at a constant temperature in a water vapor environment at 650°C for 150 hours, the oxidation weight gain of the blank sample reached 8.53mg / cm 2 , while the oxidation weight gain of the sample modified by adding rare earth is only 0.12mg / cm 2 . No surface cracks and oxide film peeling were found on the surface of the sample with rare earth added. figure 1 , figure 2 For adding rare earth Y 2 o 3 The surface topography and energy spectrum analysis results of the sample oxidized in water v...

Embodiment 2

[0019] Embodiment 2: raw material: rare earth La purity ≥ 95.00%, T91 steel pipe.

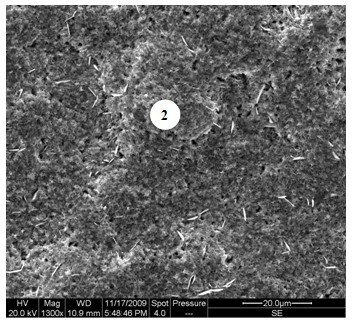

[0020] Bake the required T91 or P91 steel in a protective atmosphere and put it into an induction furnace for smelting. After the temperature rises to 1600°C, add rare earth La under the protection of argon, stir, stand still, pour, and cool to obtain rare earth-containing steel. T91 and P91 steel. After the modified sample was oxidized at a constant temperature in a water vapor environment at 650°C for 150 hours, the oxidation weight gain of the sample modified by adding rare earth was only 0.23mg / cm 2 . No surface cracks and oxide film peeling were found on the surface of the sample with rare earth added. Figure 5 This is the surface topography of the sample after adding the rare earth La and oxidizing it in water vapor at 650°C for 150 hours. In the figure, it can be seen that Cr-rich oxides are formed on the surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com