Method for preparing porous starch microsphere loaded potassium ferrate sewage treatment complexing agent

A technology of potassium ferrate and porous starch, applied in the field of water treatment, to achieve the effect of improving water treatment effect, no environmental toxicity, and increasing water treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Weigh 3.0g of potassium ferrate and dissolve it in 10mL of KOH aqueous solution with pH=12. After completely dissolving, add 2.0g of porous starch microspheres, stir slowly at room temperature, and an adsorption loading reaction occurs for 24h. After the reaction is completed, filter and filter The cake was dried in a vacuum oven at 50°C for 20 hours, and weighed to obtain 4.8 g of porous starch microsphere-loaded potassium ferrate composite.

[0016] Add 4.0g of porous starch microsphere-loaded potassium ferrate compound, 1.5g of polyferric sulfate, and 0.8g of diatomaceous earth into a drying container, and stir and mix evenly to obtain a porous starch microsphere-loaded potassium ferrate sewage treatment composite agent , sealed and preserved.

Embodiment 2

[0018] Weigh 3.0g of potassium ferrate and dissolve it in 10mL of KOH aqueous solution with pH=12. After the solution is completely dissolved, add 2.0g of porous starch microspheres and stir slowly at room temperature for 24 hours of adsorption and loading reaction. After the reaction, filter, put the filter cake in a vacuum drying oven at 50° C. for 20 hours, and weigh it to obtain 4.8 g of porous starch microsphere-loaded potassium ferrate composite.

[0019] Add 4.0g of porous starch microsphere-loaded potassium ferrate compound, 1.0g of polyferric sulfate, and 0.8g of diatomaceous earth into a drying container, and stir and mix evenly to obtain a porous starch microsphere-loaded potassium ferrate sewage treatment composite agent , sealed and preserved.

Embodiment 3

[0021] Weigh 3.0g of potassium ferrate and dissolve it in 10mL of KOH aqueous solution with pH=12. After completely dissolving, add 1.5g of porous starch microspheres and stir slowly at room temperature, and the adsorption loading reaction occurs for 24h. After the reaction, filter, put the filter cake in a vacuum drying oven at 50° C. for 20 hours, and weigh it to obtain 4.3 g of porous starch microsphere-supported potassium ferrate composite.

[0022] Add 4.0g of porous starch microsphere-loaded potassium ferrate compound, 1.6g of polyferric sulfate, and 0.8g of diatomaceous earth into a drying container, and stir and mix evenly to obtain a porous starch microsphere-loaded potassium ferrate sewage treatment composite agent , sealed and preserved.

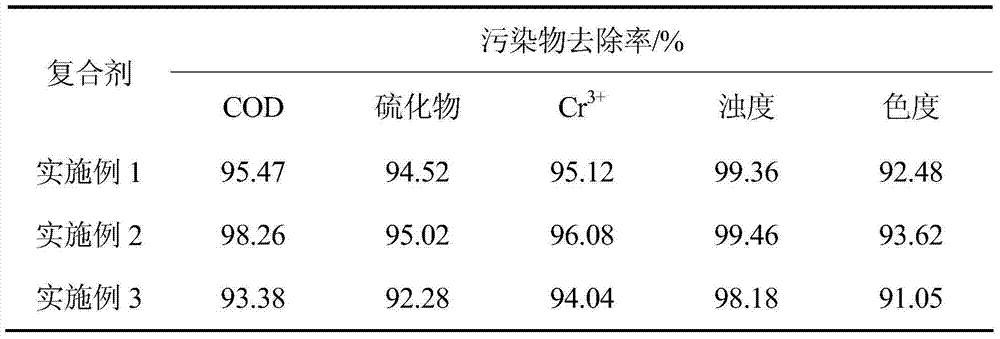

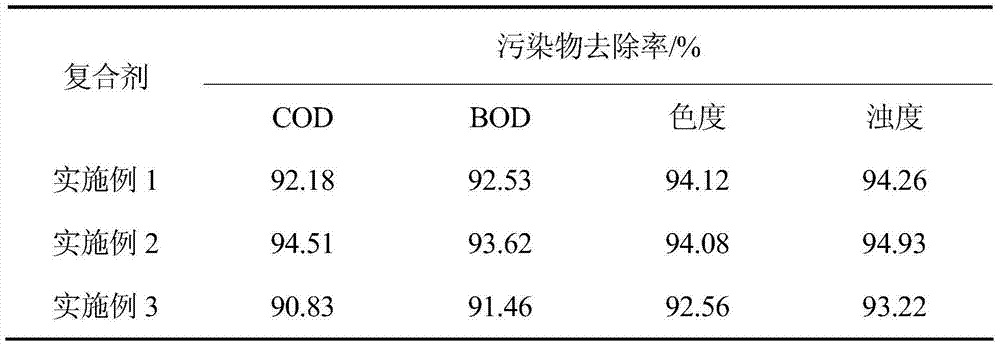

[0023] Specific use effect

[0024] Wastewater 1: The comprehensive tannery wastewater used in the experiment comes from a tannery in Haining City, Zhejiang Province. The wastewater has not been treated in any way. Its pH value i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com