MXene loaded PtRhFe ternary alloy catalyst, and preparation method and formula thereof

A ternary alloy and catalyst technology, applied in the field of electrochemical catalysis, can solve the problems of scarce reserves and high cost of platinum

- Summary

- Abstract

- Description

- Claims

- Application Information

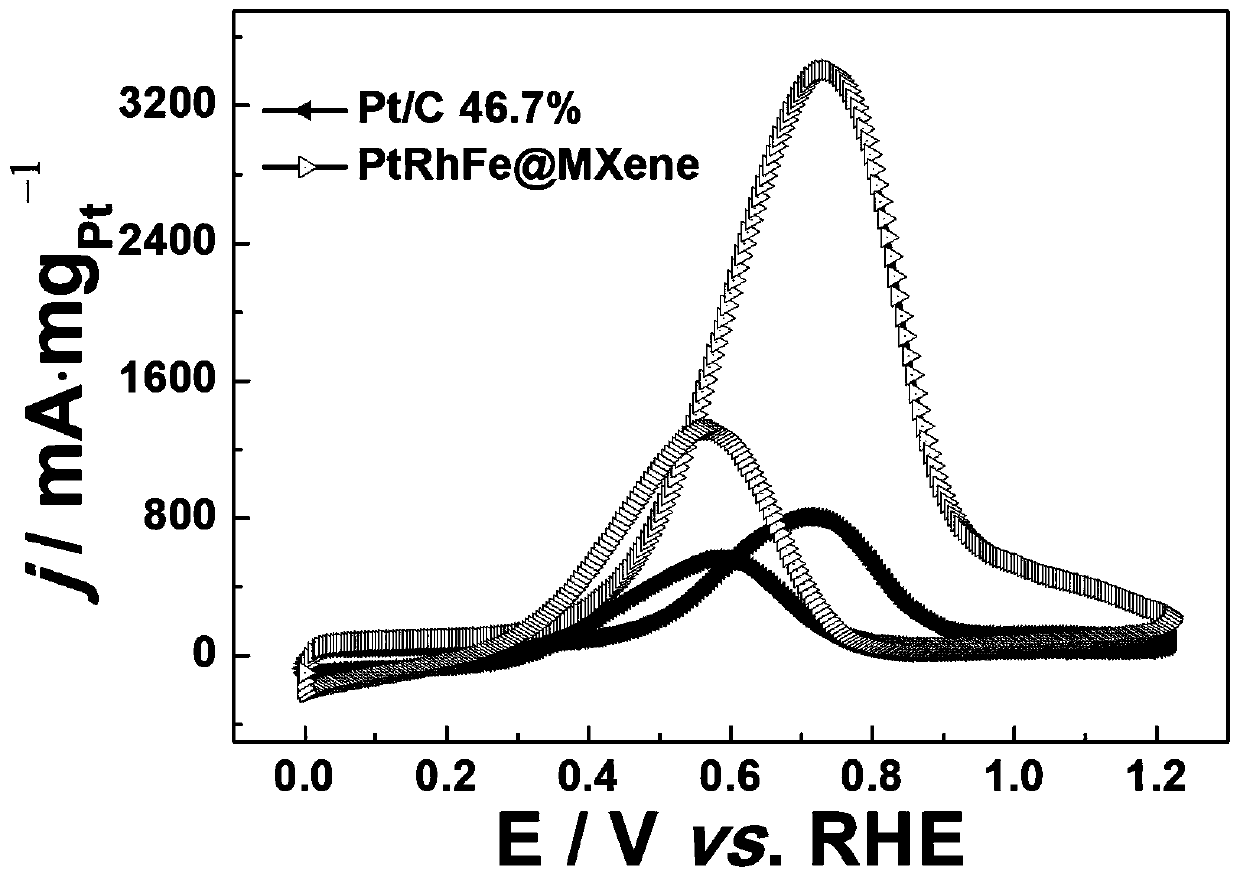

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

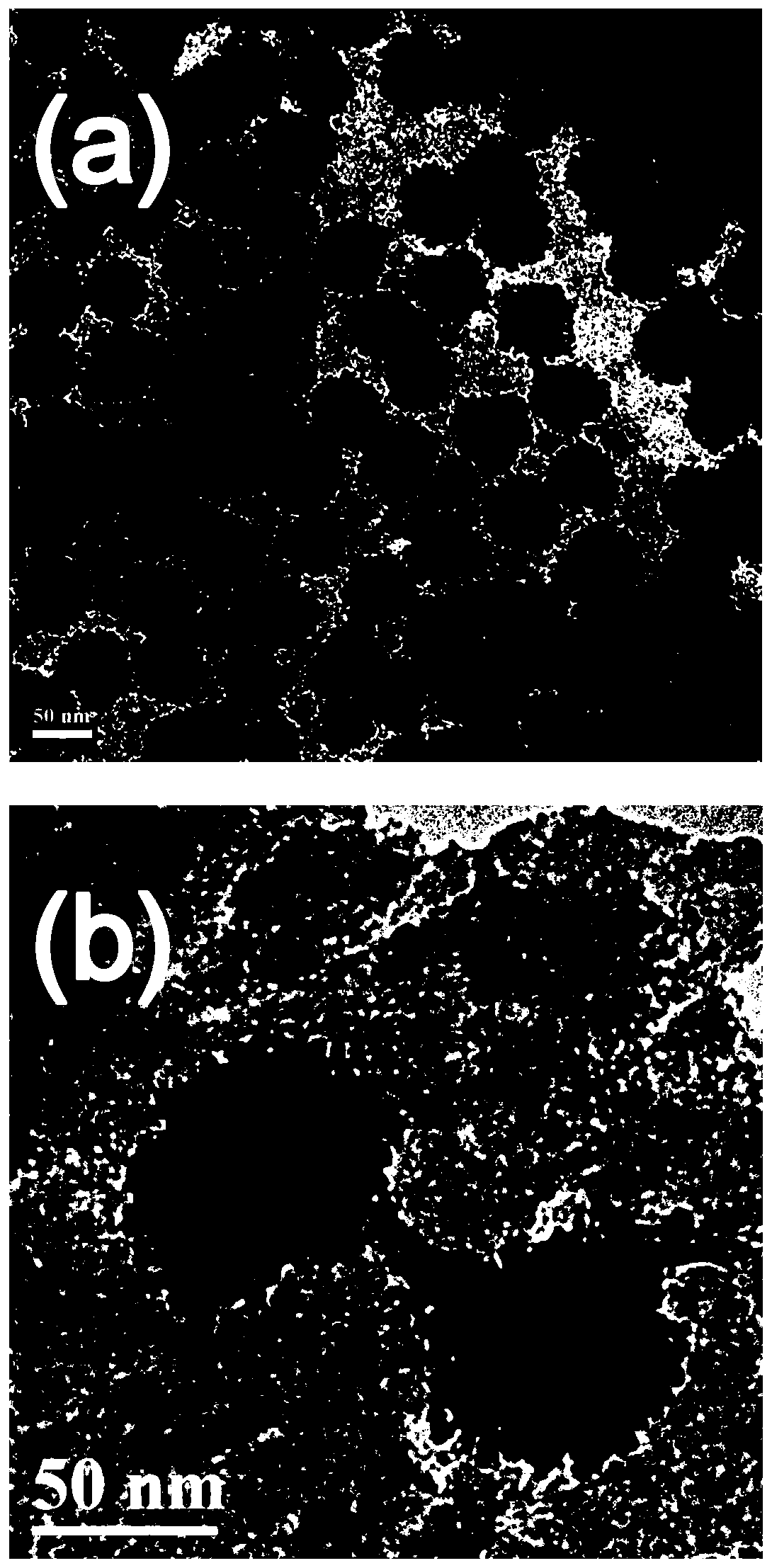

[0060] A preparation method of a porous spherical PtRhFe ternary alloy catalyst supported by two-dimensional material MXene nanosheets, the specific operation steps are as follows:

[0061] Step 1, measure 10 milliliters of oleylamine with a graduated cylinder, pour it into a 50 milliliter polytetrafluoroethylene hydrothermal kettle and carry out magnetic stirring; Weigh 26.5 milligrams (0.0513 millimoles) of chloroplatinic acid powder, ) of rhodium chloride powder, 18 mg (0.0509 mmol) of iron acetylacetonate powder, 350 mg (0.9604 mmol) of cetyltrimethylammonium bromide powder and 100 mg of Ti 3 C 2 Add MXene powder one by one (the order of adding each component is not strictly required) into a 50 ml polytetrafluoroethylene hydrothermal kettle and stir until the solution is evenly mixed;

[0062] Step 2. After the solution in step 1 is fully stirred and mixed evenly, seal the shell of the hydrothermal kettle tightly to carry out hydrothermal reaction. The hydrothermal temper...

Embodiment 2

[0067] A preparation method of a porous spherical PtRhFe ternary alloy catalyst supported by two-dimensional material MXene nanosheets, the specific operation steps are as follows:

[0068] (1) Measure 10 milliliters of oleic acid with a graduated cylinder, pour it into a 50 milliliter polytetrafluoroethylene hydrothermal kettle and carry out magnetic stirring; weigh 20.2 milligrams (0.0513 millimoles) of platinum acetylacetonate powder, 2.94 milligrams (0.0111 millimoles) ) of rhodium chloride powder, 10 mg (0.0617 mmol) of ferric chloride powder, 200 mg (0.625 mmol) of cetyltrimethylammonium chloride powder and 100 mg of Ti 2 Add C MXene powder one by one to 50 milliliters of polytetrafluoroethylene hydrothermal kettle and stir until the solution is evenly mixed;

[0069] (2) After the solution in step (1) is fully stirred and mixed evenly, seal the shell of the hydrothermal kettle tightly for hydrothermal reaction, the hydrothermal temperature is 170 degrees Celsius, the ho...

Embodiment 3

[0072] A preparation method of a porous spherical PtRhFe ternary alloy catalyst supported by two-dimensional material MXene nanosheets, the specific operation steps are as follows:

[0073] (1) Measure 10 milliliters of dimethylformamide with a graduated cylinder, pour it into a 50 milliliter polytetrafluoroethylene hydrothermal kettle and carry out magnetic stirring; weigh 37.4 milligrams (0.0769 millimoles) of potassium chloroplatinate powder, 2.46 milligrams (0.0085 mmol) of rhodium nitrate powder, 6.17 mg (0.0256 mmol) of iron nitrate powder, 200 mg (0.621 mmol) of tetrabutylammonium bromide powder and 200 mg of Ti 3 C 2 Add MXene powder one by one to 50 milliliters of polytetrafluoroethylene hydrothermal kettle and stir until the solution is evenly mixed;

[0074] (2) After the solution in step (1) is fully stirred and mixed evenly, the shell of the hydrothermal kettle is tightly sealed for hydrothermal reaction, the hydrothermal temperature is 150 degrees Celsius, the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com