Catalyst for synthesizing methanol by direct hydrogenation of carbon dioxide and preparation method thereof

A carbon dioxide and methanol synthesis technology, which is applied in the preparation of organic compounds, catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of poor methanol selectivity and low conversion rate of carbon dioxide, and achieve high performance Stabilize and overcome the effect of low conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

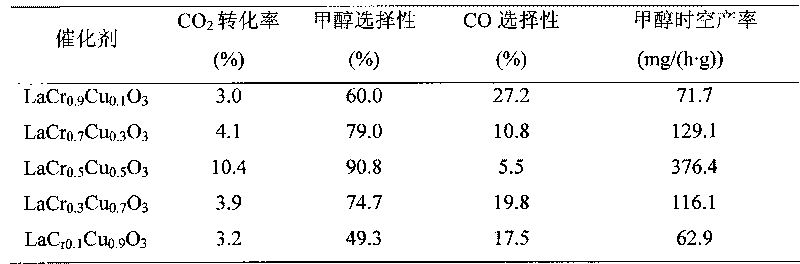

Embodiment 1

[0017] Copper nitrate, chromium nitrate, lanthanum nitrate and citric acid were formulated into a 0.5M mixed solution at a ratio of 0.1:0.9:1.0:1.5. It becomes a sol under the irradiation of an infrared lamp, and is quickly ignited on an electric furnace. The obtained solid powder is calcined at 400°C for 2 hours, and then calcined at 800°C for 4 hours. The resulting perovskite LaCr 0.9 Cu 0.1 o 3 Precursor, compressed into 40-60 mesh. Take 0.5g of the precursor and reduce it at 350°C under normal pressure for 6h (flow rate 60ml / min) and switch to the reaction raw material gas for reaction. The reaction conditions are: pressure 2.0MPa, temperature 250°C, V(H 2 ) / V(CO 2 ) / V(N 2 )=64:31:5, GHSV=9000ml / (h.g), the product is detected and analyzed by TCD and FID detectors, and the conversion rate of carbon dioxide, methanol selectivity and other by-product selectivity are shown in Table 1.

Embodiment 2

[0019] Copper nitrate, chromium nitrate, lanthanum nitrate and citric acid were formulated into a 0.4M mixed solution at a ratio of 0.3:0.7:1.0:1.0. It becomes a gel under the irradiation of infrared lamp, calcined at 350°C for 2h, and then calcined at 750°C for 4h. The obtained perovskite LaCr 0.7 Cu 0.3 o 3 It is the oxidation state precursor of the catalyst, and the catalytic activity evaluation is the same as in Example 1, and the results are shown in Table 1.

Embodiment 3

[0021] Copper nitrate, chromium nitrate, lanthanum nitrate and citric acid have been formulated into a 0.5M mixed solution at a ratio of 0.5:0.5:1.0:2.0. It becomes a gel under the irradiation of infrared lamp, calcined at 350°C for 2h, and then calcined at 750°C for 4h. The obtained perovskite LaCr 0.5 Cu 0.5 o 3 It is an oxidized state precursor, and the catalyst activity evaluation is the same as in Example 1, and the evaluation results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com