Method for preparing methanol synthesizing catalyst

A technology for synthesizing methanol and catalysts, which is applied in the direction of catalyst activation/preparation, preparation of organic compounds, chemical instruments and methods, etc. It can solve the problems of easy deactivation of catalysts and achieve improved methanol performance, uniform particle size distribution, and high density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

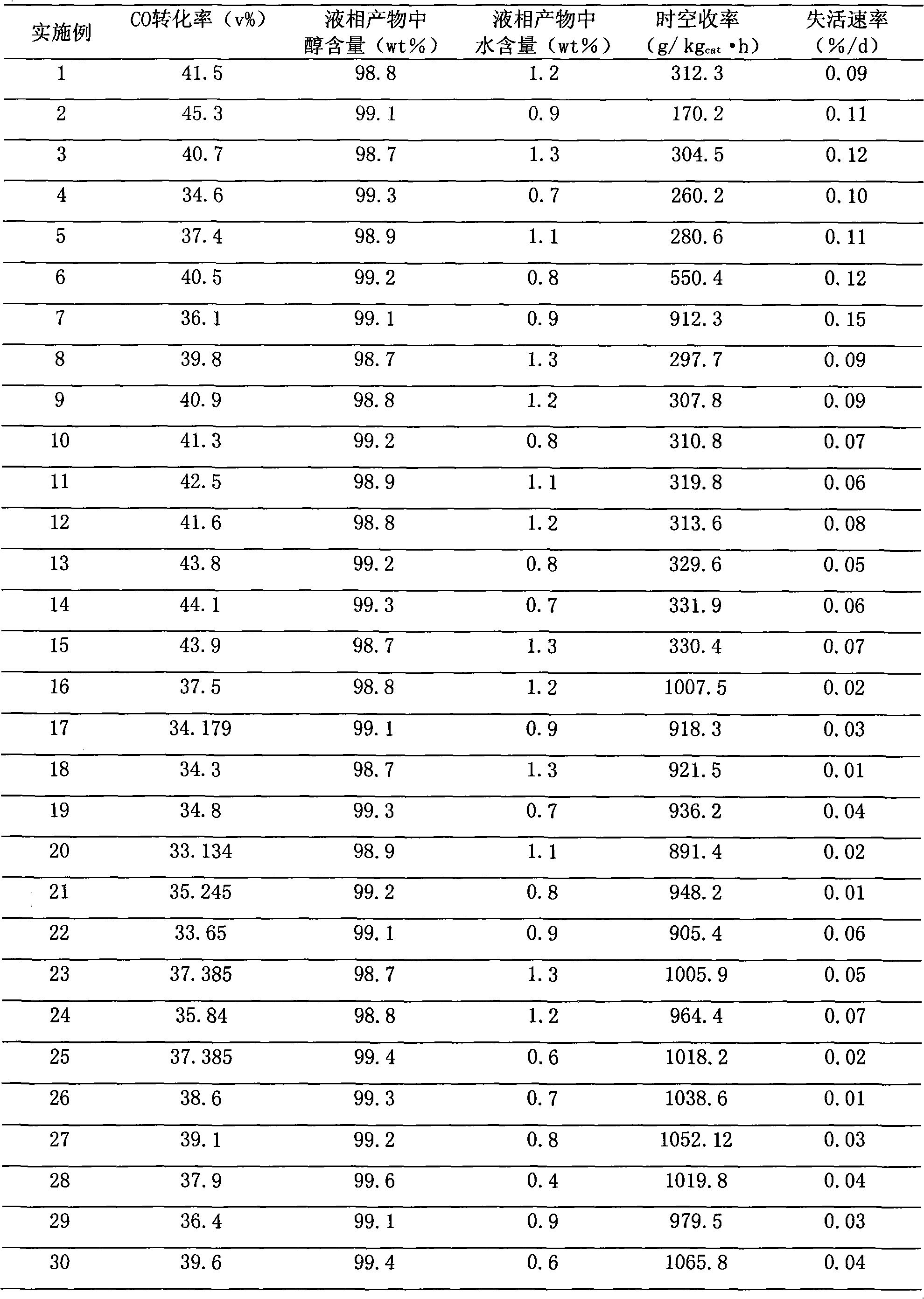

Examples

Embodiment 1

[0016] The copper / zinc / aluminum mol ratio that preparation concentration is 1.5mol / L is the mixed nitrate solution of 64 / 32 / 4 and the sodium carbonate solution that concentration is 1.3mol / L respectively 500ml, under 80 ℃ and fully stirring condition, And keep the pH of the precipitation mother liquid in the range of 8.0±0.2, carry out the precipitation reaction in a constant temperature water bath, after the precipitation is completed, continue to stir and age under microwave radiation at 90°C for 2 hours, and then wash the precipitated product with deionized water until it is sodium-free Until the ions are detected, dry in an oven at 110°C for 11 hours, and finally bake in an air atmosphere at 320°C for 3 hours. The methanol synthesis reaction is carried out in a mechanically stirred slurry bed reactor with a volume of 500ml, and the reaction conditions are 240°C of temperature, 4MPa of pressure, (H 2 -CO 2 ) / (CO+CO 2 )=2, air speed 1600L / kg cat h. The results obtained a...

Embodiment 2

[0018] The copper / zinc / aluminum mol ratio that preparation concentration is 1.5mol / L is the mixed nitrate solution of 64 / 32 / 4 and the sodium carbonate solution that concentration is 1.3mol / L respectively 500ml, under 80 ℃ and fully stirring condition, And keep the pH of the precipitation mother liquid in the range of 8.0±0.2, carry out the precipitation reaction in the microwave, after the precipitation is completed, age it in a constant temperature water bath at a temperature of 80°C and continue to stir for 1 hour, and then wash the precipitated product with deionized water until it is free Until the sodium ion is detected, dry it in an oven for 11 hours, and finally bake it in a muffle furnace at 350°C for 1 hour in an air atmosphere. The methanol synthesis reaction is carried out in a mechanically stirred slurry bed reactor with a volume of 500ml, and the reaction conditions are 240°C of temperature, 5.0MPa of pressure, (H 2 -CO 2 ) / (CO+CO 2 )=2, air speed 800L / kg cat h...

Embodiment 3

[0020] Prepare 1.5mol / L copper / zinc / aluminum mixed nitrate solution with a molar ratio of 64 / 32 / 4 and 1.3mol / L sodium carbonate solution with a concentration of 500ml respectively. , and keep the pH of the precipitation mother liquid in the range of 7.5±0.2, carry out the precipitation reaction, after the precipitation is completed, age in a constant temperature water bath at 60°C and continue to stir for 3 hours, and then wash the precipitated product with deionized water until it is free of sodium ions. Dry the filter cake in a microwave oven at 110°C for 3 hours, and finally bake it in a microwave oven at 370°C for 1 hour in an air atmosphere. The methanol synthesis reaction is carried out in a mechanically stirred slurry bed reactor with a volume of 500ml, and the reaction conditions are 240°C of temperature, 5.0MPa of pressure, (H 2 -CO 2 ) / (CO+CO 2 )=1.5, air speed 2000L / kg cat h. The reaction results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com