Catalyst for synthesizing ethylene glycol by oxalate hydrogenation, and preparation method and application method of catalyst

A catalyst and ethylene glycol technology, applied in the direction of catalyst activation/preparation, carboxylate preparation, chemical instruments and methods, etc., can solve the problems of increased production cost, no breakthrough development, high performance requirements, etc., and achieve inhibition of agglomeration , shorten the pretreatment time, solve the effect of high temperature and easy sintering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Catalyst preparation

[0023] A. Dissolve 10.6g of copper nitrate and 0.5g of mannitol in 100g of distilled water. After fully dissolving, put them in an ultrasonic instrument for 20 minutes of ultrasonic oscillation with an ultrasonic frequency of 25kHz.

[0024] B. Add 5.0g of urea to the above solution and stir to dissolve, then add 20ml of ammonia water and stir for 30min,

[0025] C. Finally add 21g SiO drop by drop 2 For the alkaline silica sol with a content of 40%, the mixed solution was mechanically stirred and placed in a water bath at 80° C. for 3 to 6 hours, and then stopped heating until the pH value of the solution was close to 7. The filter cake was obtained by filtration, and the filter cake was washed several times with distilled water, and the resulting filter cake was dried in air at 120°C for 24 hours to obtain Cu / SiO 2 catalyst precursors.

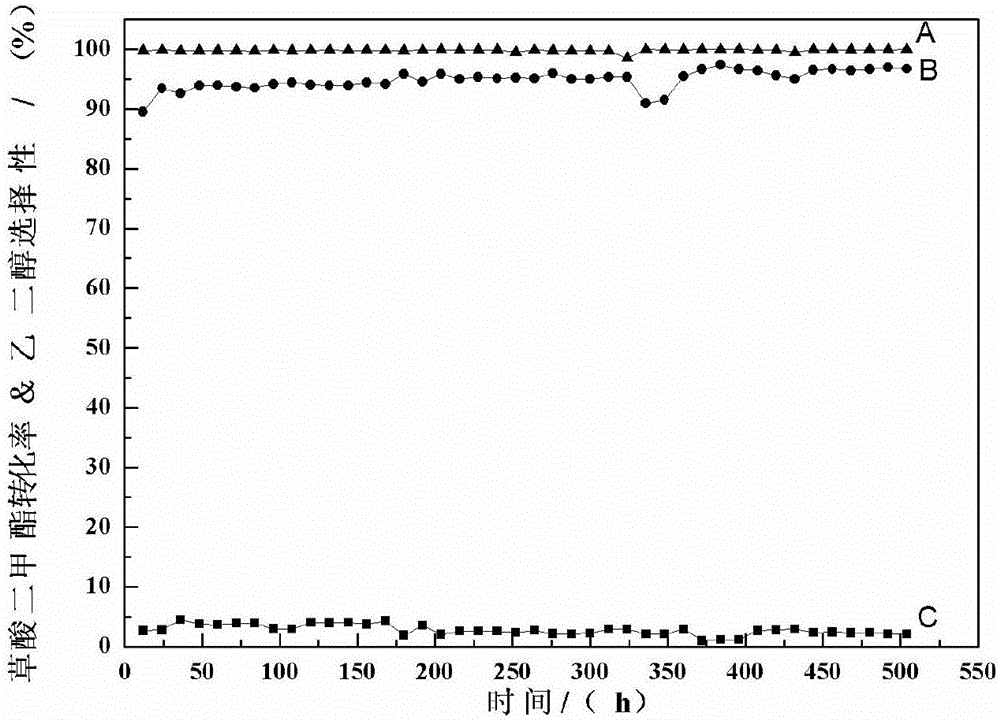

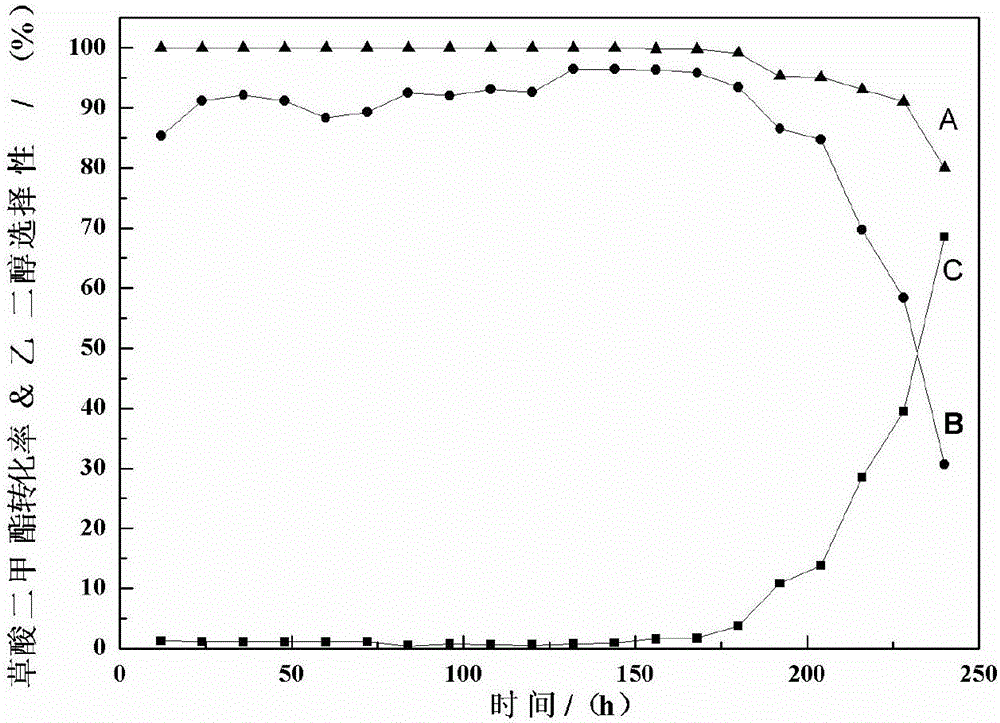

[0026] Cu / SiO 2 The precursor of the catalyst was pressed into tablets and sieved to obtain particles wit...

Embodiment 2

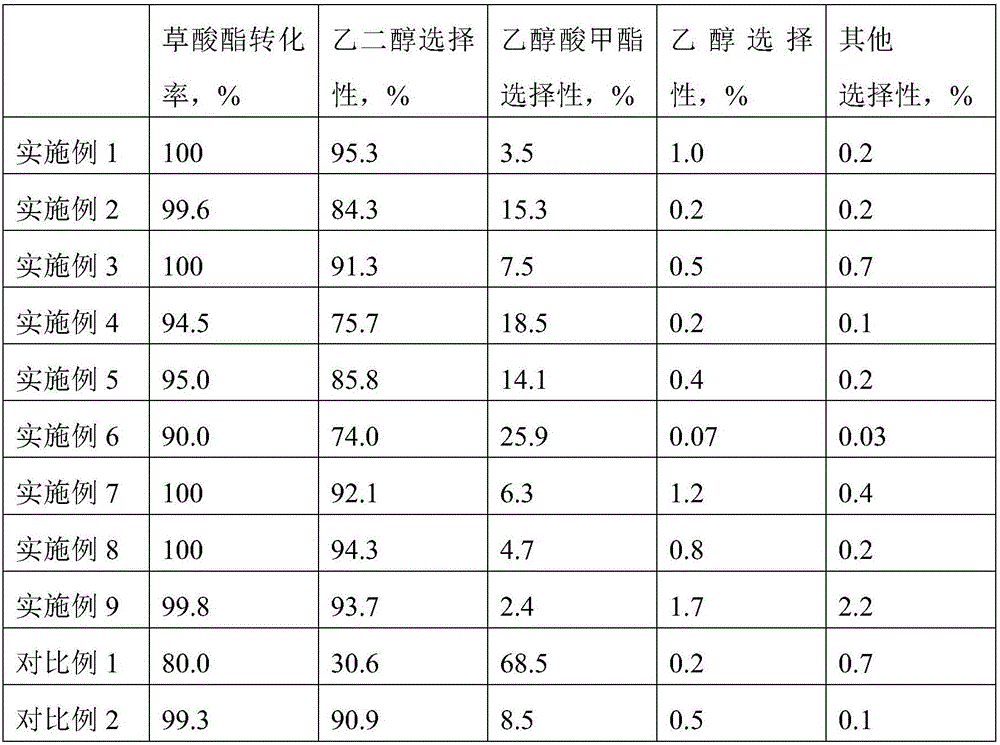

[0030] In Example 1, the mannitol in the catalyst preparation step was changed to 2.0 g of citric acid, namely the cost example.

[0031] The performance evaluation conditions are the same as in Example 1, and the results of selective hydrogenation of dimethyl oxalate to ethylene glycol after 24 hours are shown in Table 1.

Embodiment 3

[0033] In Example 1, the mannitol in the catalyst preparation step was changed to 1.0 g of glucose, which is the cost example.

[0034] The performance evaluation conditions are the same as in Example 1, and the results of selective hydrogenation of dimethyl oxalate to ethylene glycol after 24 hours are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com