Full-degradable injection product and preparation method therefor

An injection molding product, fully degradable technology, applied in the field of fully degradable composite materials, can solve the problems of polybutylene succinate compatibility price difference, poor heat resistance of polylactic acid, and restrictions on popularization and application, and achieve short heat treatment time, The effect of low production cost and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

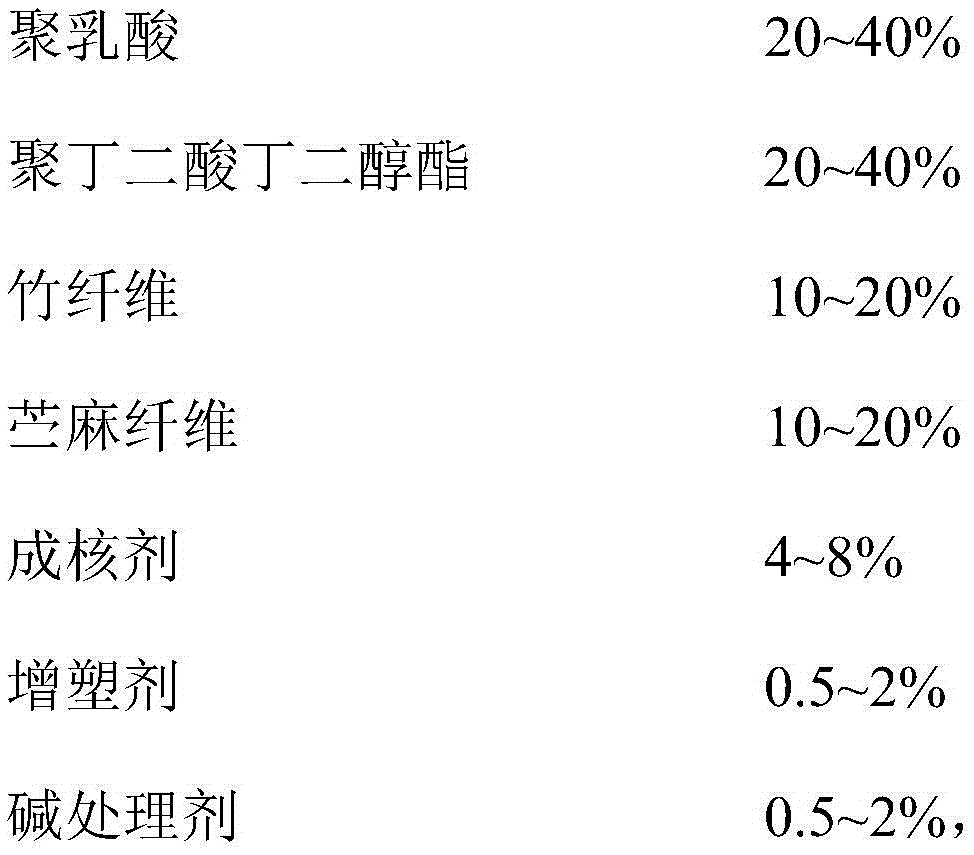

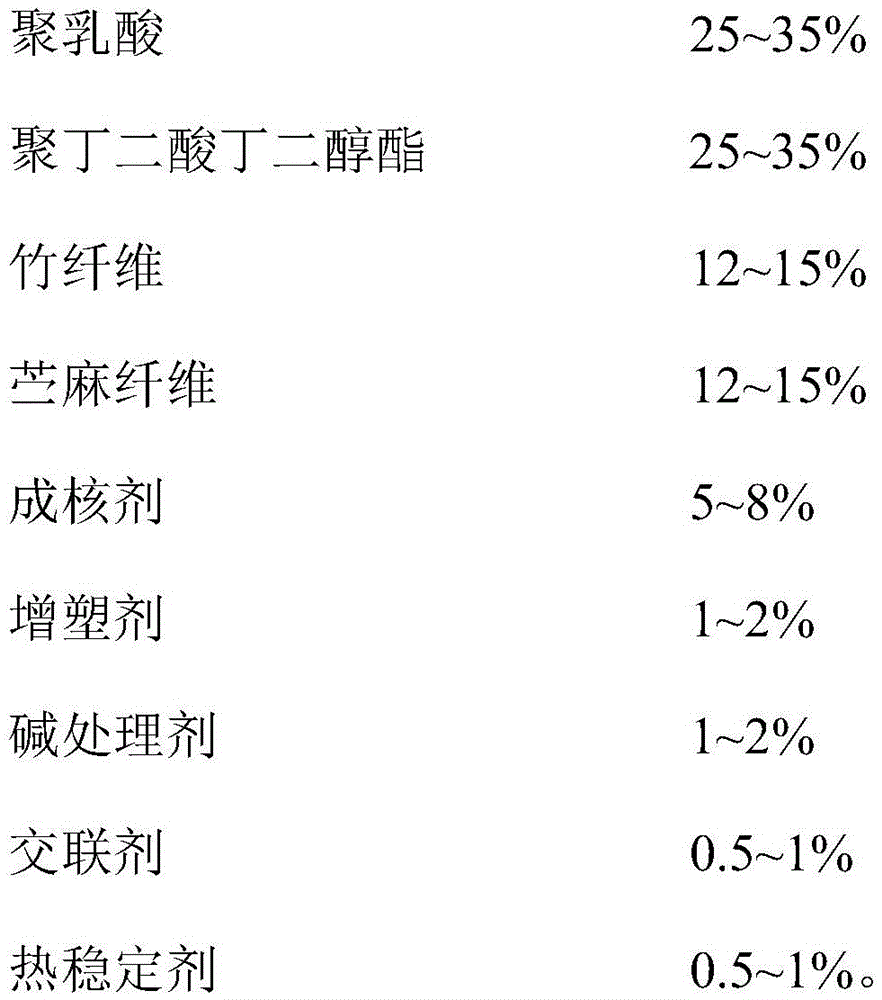

Method used

Image

Examples

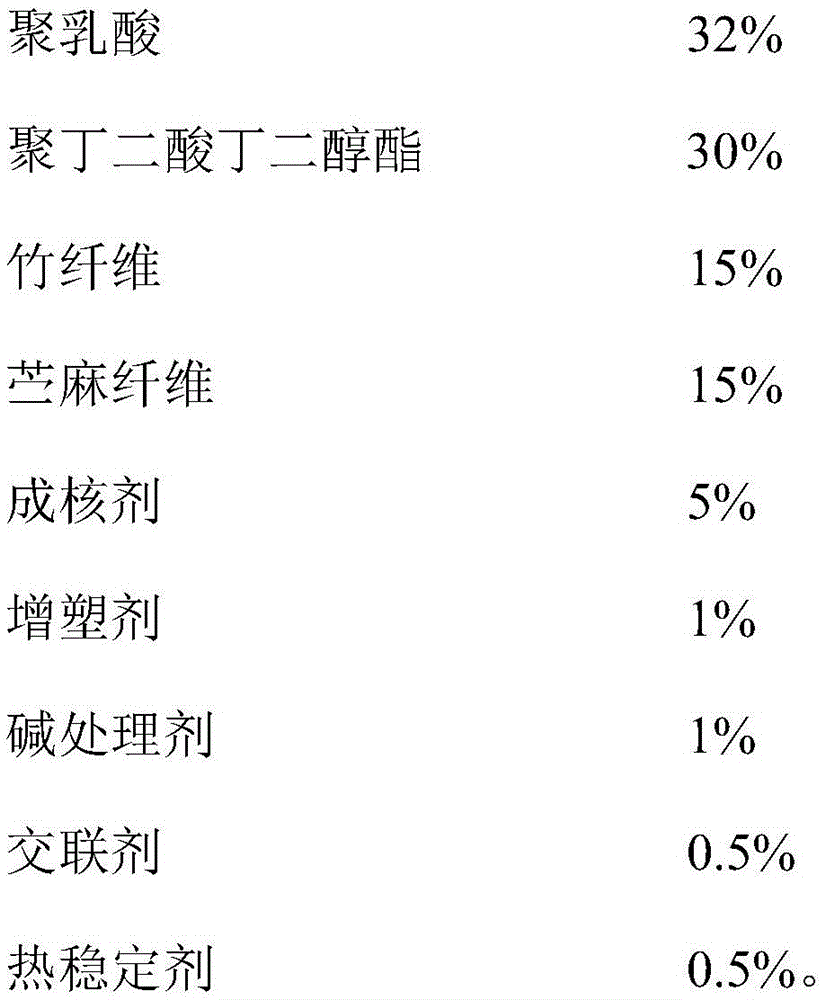

Embodiment 1

[0029] By weight, the above 32 parts of polylactic acid, 30 parts of polybutylene succinate, 15 parts of bamboo fiber, 15 parts of ramie fiber, 5 parts of sebacic acid dibenzohydrazide nucleating agent, 1 part of acetyl citrate three Butyl ester plasticizer, 1 part of sodium hydroxide alkali treatment agent, 0.5 part of triglycidyl isocyanurate crosslinking agent and 0.5 part of dibasic lead stearate heat stabilizer raw materials are put into the high mixer according to the above ratio 5min; put the mixed raw materials into a twin-screw extruder for granulation, the length-to-diameter ratio of the screw is 1:42, the screw speed is 400rpm, and the heating temperature of each section of the screw is 150°C, 165°C, 175°C, 185°C, 170°C , 160°C; Put the prepared pellets into the injection molding machine, according to the required product mold, injection molding, the heating temperature of the screw of the injection molding machine is 160°C, and the pressure is 45Mpa; the injection m...

Embodiment 2~4

[0031] Process is identical with embodiment 1, and difference is the performance of formula, preparation condition and gained product, as shown in table 1 respectively:

[0032] Table 1

[0033]

[0034] Generally, its tensile strength of existing polylactic acid product is all lower than 40MPa, and elongation at break is in the scope of 5~10%, and heat distortion temperature is lower than 80 ℃, and can find out from Table 1: the present invention prepares The tensile strength, elongation at break and heat distortion temperature of the fully degradable injection molding product polylactic acid are all greater than the existing polylactic acid, that is to say, the fully degradable polylactic acid prepared by the present invention ensures its degradability. , also has excellent toughness and heat resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com