Waste residue microcrystal glass and its preparation method

A technology of glass-ceramics and waste glass, which is applied in the field of preparing glass-ceramics, can solve the problems of insufficient utilization of resources, large discharge of waste glass, occupation of land resources, etc., and achieve high utilization rate, resource saving, and utilization of various types many effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

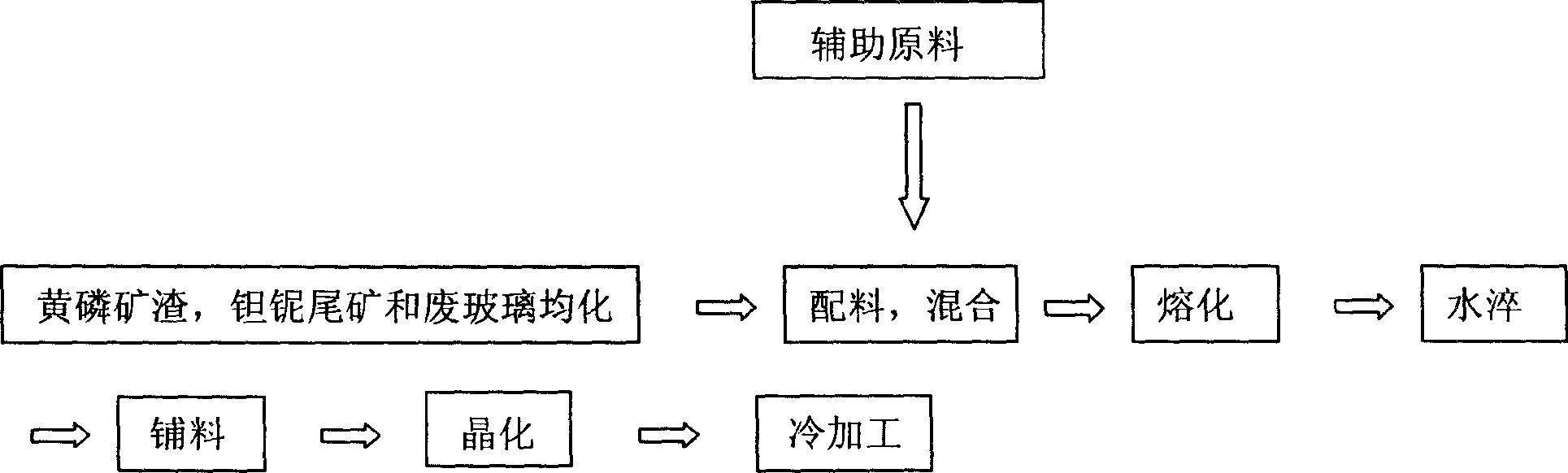

[0044] like figure 1 Shown, the main chemical composition of yellow phosphorus slag is (percentage by weight): P 2 o 5 : 2.40%, SiO 2 : 41.72%, CaO: 51.95%; the main chemical composition of tantalum and niobium tailings is (weight percent): SiO 2 : 75.74%, Al 2 o 3 : 14.91%, Na 2 O: 4.30%, K 2 O: 1.87%, CaO: 1.23%; The chemical composition of waste glass is (percentage by weight): SiO 2 : 73.00%, Al 2 o 3 : 1.00%, Na 2 O: 13.00%, K 2 O: 0.50%, CaO: 12.50%. According to the following proportions (percentage by weight): yellow phosphorus slag: 29.13, tantalum and niobium tailings: 26.05, waste glass: 13.82, quartz sand: 26.56, zinc oxide: 1.94, barium carbonate: 2.50.

[0045]Yellow phosphorus slag, tantalum-niobium tailings and waste glass are pre-homogenized, crushed and screened to ensure uniform composition of raw materials. Various raw materials are weighed and then mixed to prepare a glass batch. The batch is melted and clarified at 1340±10°C, and the molten ...

Embodiment 2

[0047] The main chemical composition of yellow phosphorus slag is (percentage by weight): P 2 o 5 : 2.18%, SiO 2 : 37.95%, CaO: 46.09%; the main chemical composition of tantalum and niobium tailings is (weight percent): SiO 2 : 71.60%, Al 2 o 3 : 16.45%, Na 2 O: 6.60%, K 2 O: 2.20%; Waste glass chemical composition is (percentage by weight): SiO 2 : 73.00%, Al 2 o 3 : 1.00%, Na 2 O: 13.00%, K 2 O: 0.50%, CaO: 12.50%. According to the following proportions (percentage by weight): yellow phosphorus slag: 37.26, tantalum and niobium tailings: 11.18, waste glass: 15.84, quartz sand: 31.45, zinc oxide: 1.86, barium carbonate: 2.41.

[0048] Yellow phosphorus slag, tantalum-niobium tailings and waste glass are pre-homogenized, crushed and screened to ensure uniform composition of raw materials. Various raw materials are weighed and then mixed to prepare a glass batch. The batch material is melted and clarified at 1370±10°C, and the melted glass liquid is water-quenched ...

Embodiment 3

[0050] The main chemical composition of yellow phosphorus slag is (percentage by weight): P 2 o 5 : 2.18%, SiO 2 : 37.95%, CaO: 46.09%; the main chemical composition of tantalum and niobium tailings is (weight percent): SiO 2 : 75.74%, Al 2 o 3 : 14.91%, Na 2 O: 4.3%, K 2 O: 1.87%, CaO: 1.23%; The chemical composition of waste glass is (percentage by weight): SiO 2 : 73.00%, Al 2 o 3 : 1.00%, Na 2 O: 13.00%, K 2 O: 0.50%, CaO: 12.50%. According to the following proportions (percentage by weight): yellow phosphorus slag: 52.86, tantalum niobium tailings: 28.71, waste glass: 10.44, quartz sand: 4.00, zinc oxide: 1.74, barium carbonate: 2.25.

[0051] Yellow phosphorus slag, tantalum-niobium tailings and waste glass are pre-homogenized, crushed and screened to ensure uniform composition of raw materials. Various raw materials are weighed and then mixed to prepare a glass batch. The batch material is melted and clarified at 1370±10°C, and the melted glass liquid is wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com