Low-compression ratio hot-rolled 9Ni steel thick plate and manufacturing method thereof

A technology with low compression ratio and manufacturing method, which is applied in the field of steel rolling technology, can solve the problems of difficulty in guaranteeing the distribution uniformity of residual deformation stress, thermal stress and phase transformation stress, shorten the production process, increase the cost of alloy, etc., and achieve short heat treatment time , good plate shape, and the effect of reducing alloy cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

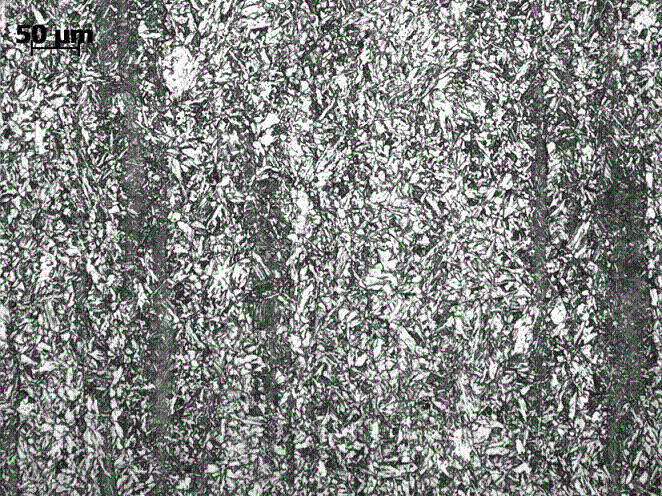

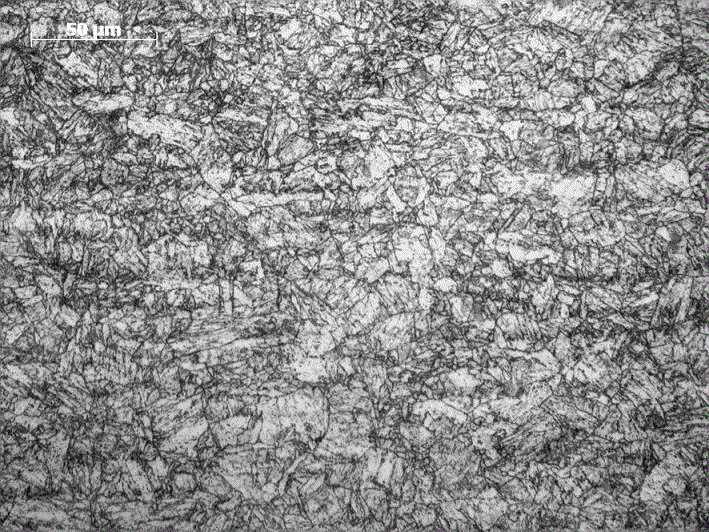

[0030] A low compression ratio hot-rolled 9Ni steel thick plate provided in this example contains the following chemical components and their mass percentages: C: 0.066%, Si: 0.17%, Mn: 0.60%, S: 0.0012%, P: 0.0044%, Ni: 9.15%, Alt: 0.030%, and the balance is Fe and impurities. The microstructure of the thick steel plate is: tempered martensite as the matrix plus a mixed structure of 9% reverse transformed austenite second phase.

Embodiment 2

[0032] A low compression ratio hot-rolled 9Ni steel thick plate provided in this example contains the following chemical components and their mass percentages: C: 0.038%, Si: 0.19%, Mn: 0.64%, S: 0.0007%, P: 0.0042%, Ni: 9.07%, Alt: 0.032%, and the balance is Fe and impurities. The structure of the thick steel plate is: tempered martensite as the matrix plus a mixed structure of 4% reverse transformed austenite second phase.

Embodiment 3

[0034] A low reduction ratio hot-rolled 9Ni steel thick plate provided in this example contains the following chemical components and their mass percentages: C: 0.043%, Si: 0.23%, Mn: 0.68%, S: 0.0010%, P: 0.0041%, Ni: 9.41%, Alt: 0.034%, and the balance is Fe and impurities. The microstructure of the thick steel plate is: tempered martensite as the matrix plus a mixed structure of 15% reverse transformed austenite second phase.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com