Fe-Si-Al soft magnetic powder

A technology of magnetic powder and iron-silicon, which is applied in the field of sendust soft magnetic powder and its preparation of magnetic powder cores, can solve the problems of high heat treatment temperature, insufficient performance, and insufficient environmental protection, and achieve short heat treatment time, low power consumption, and high temperature low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A preparation process of iron-silicon magnetic powder core:

[0024] (1) Preparation of magnetic powder core raw materials: smelted in a vacuum induction furnace, the chemical composition is: 9.2% Si, 5.0% Al, 0.03% Ni, 0.05% Cr, 0.06% Mn, the carbon content is controlled at 0.015%, and the rest is Fe. Cast ingots in a vacuum, coarsely crush the alloy ingots, and then enter the ball mill to grind them into powders of different particle sizes, and then perform pure nitrogen protection heat treatment;

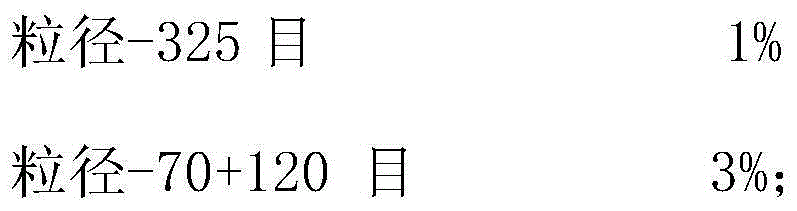

[0025] (2) Powder preparation: the particle size distribution and proportioning of the ferrosilicon magnetic powder core are:

[0026]

[0027] Then alloy melting is carried out in an open-type intermediate frequency induction furnace with a magnesia crucible, the melting temperature is 1520°C-1580°C, and the alloy melting time is 50-60 minutes;

[0028] After the alloy is smelted, the strip is made by the high-speed cooling method of the strip machine, and it is mecha...

Embodiment 2

[0041] The preparation technology of a kind of iron-silicon magnetic powder core:

[0042] (1) Preparation of magnetic powder core raw materials: smelted in a vacuum induction furnace, the chemical composition is: 9.6% Si, 5.2% Al, 0.03% Ni, 0.09% Cr, 0.06% Mn, the carbon content is controlled at 0.018%, and the rest is Fe. Cast ingots in a vacuum, coarsely crush the alloy ingots, and then enter the ball mill to grind them into powders of different particle sizes, and then perform pure nitrogen protection heat treatment;

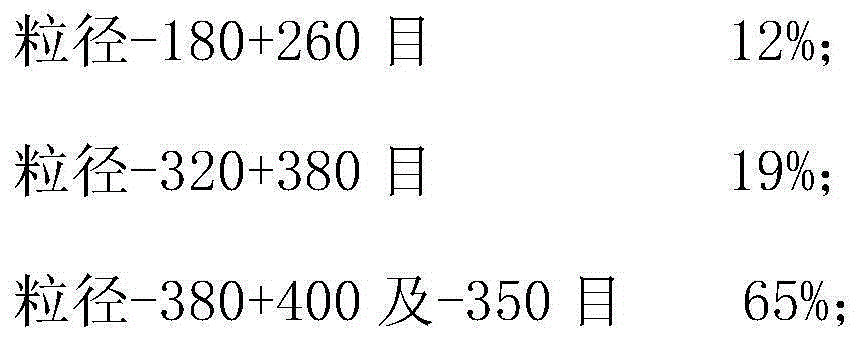

[0043] (2) Powder preparation: the particle size distribution and proportioning of the ferrosilicon magnetic powder core are:

[0044]

[0045] Then alloy melting is carried out in an open-type intermediate frequency induction furnace with a magnesia crucible, the melting temperature is 1580°C, and the alloy melting time is 50-60 minutes;

[0046] After the alloy is smelted, the strip is made by the high-speed cooling method of the strip machine, and it ...

Embodiment 3

[0060] The preparation technology of a kind of iron-silicon magnetic powder core:

[0061] (1) Preparation of magnetic powder core raw materials: smelted in a vacuum induction furnace, the chemical composition is: 9.5% Si, 5.1% Al, 0.03% Ni, 0.06% Cr, 0.06% Mn, the carbon content is controlled at 0.016%, and the rest is Fe. Cast ingots in a vacuum, coarsely crush the alloy ingots, and then enter the ball mill to grind them into powders of different particle sizes, and then perform pure nitrogen protection heat treatment;

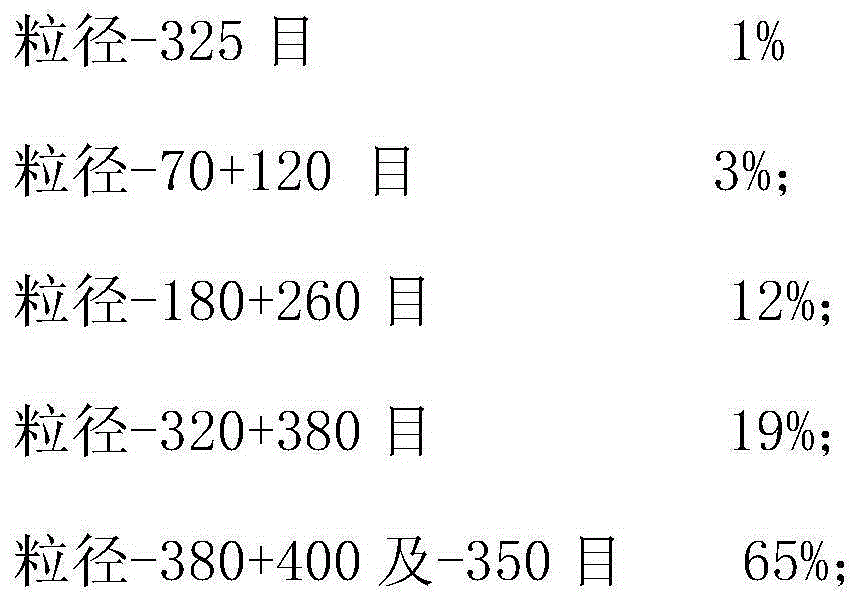

[0062] (2) Powder preparation: the particle size distribution and proportioning of the ferrosilicon magnetic powder core are:

[0063]

[0064] Then the alloy melting is carried out in an open-type intermediate frequency induction furnace with a magnesia crucible, the melting temperature is 1550°C, and the alloy melting time is 55 minutes;

[0065] After the alloy is smelted, the strip is made by the high-speed cooling method of the strip machine, and it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com