System and process for drying sludge using pulse combustion internal heating fluid bed

A fluidized bed drying and fluidized bed dryer technology, applied in dewatering/drying/concentrating sludge treatment, chemical instruments and methods, dispersed particle separation, etc., can solve the problem of long drying time, large energy consumption, and large heat loss and other problems, to achieve the effect of no dust combustion and explosion hazards, improved drying efficiency, and low environmental protection pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

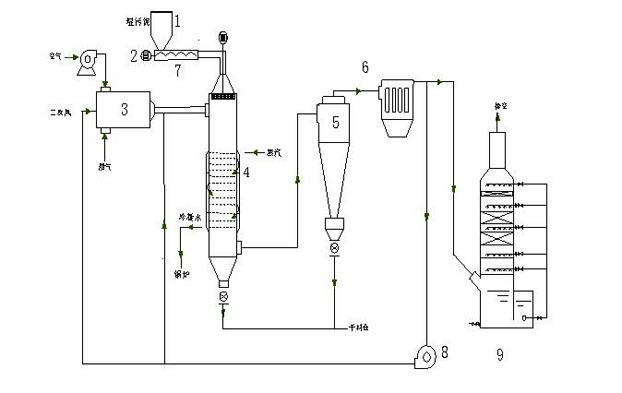

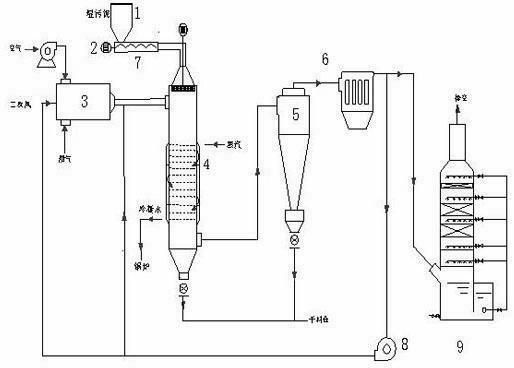

[0037] figure 1Among them, a pulsating combustion internal heating fluidized bed drying sludge system, the tail gas pipe of the pulsating burner 3 is connected to the air inlet of the internal heating fluidized bed dryer 4, and the internal heating fluidized bed dryer 4 is connected to the wet sludge supply The material granulation device and the cyclone dust collector 5 are respectively connected; the steam (superheated steam or saturated steam) enters the steam inlet of the built-in heat exchanger of the internal heating fluidized bed dryer 4 and enters the built-in heat exchanger to exchange heat with the wet sludge and then condenses Return to the boiler; the air outlet of the internal heating fluidized bed dryer 4 is connected with the cyclone dust collector 5 and the electrostatic precipitator 6 in sequence, and the tail gas after dust removal is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com