Halogen-free flame retardant irradiation-crosslinked cable material and preparation method thereof

A cable material and irradiation technology, which is applied in the field of wire and cable materials, can solve the problems such as the decline of the mechanical properties of the material, and achieve the effect of reducing the amount of addition and reducing the loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

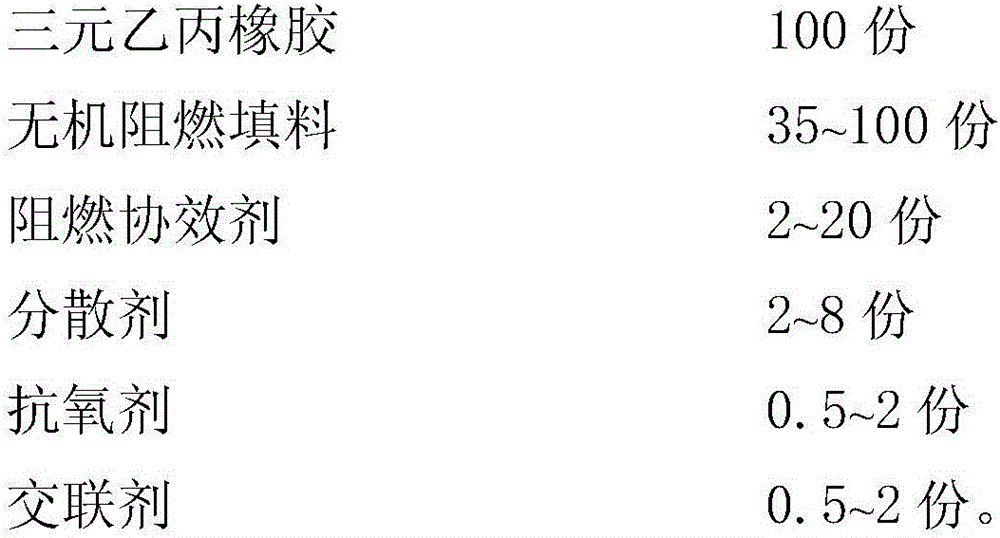

Method used

Image

Examples

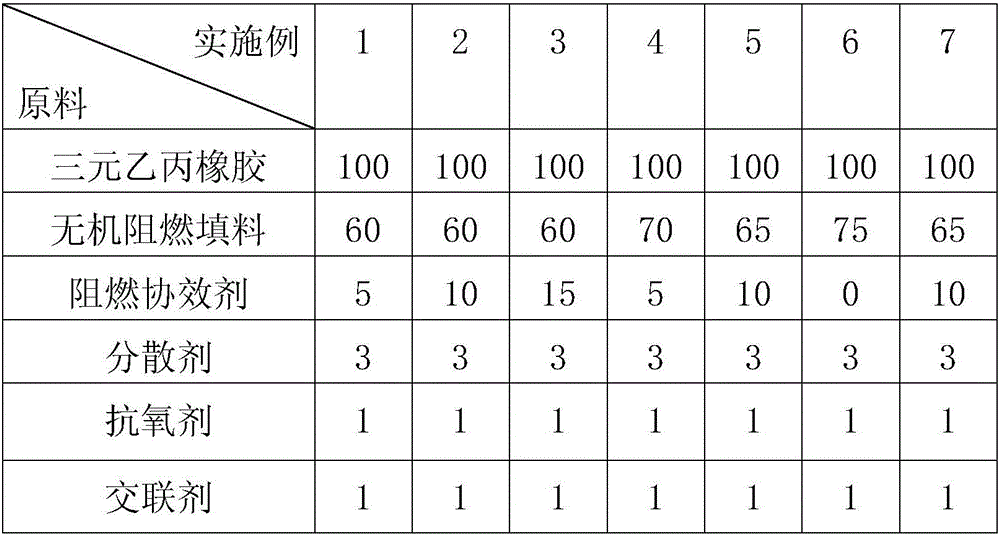

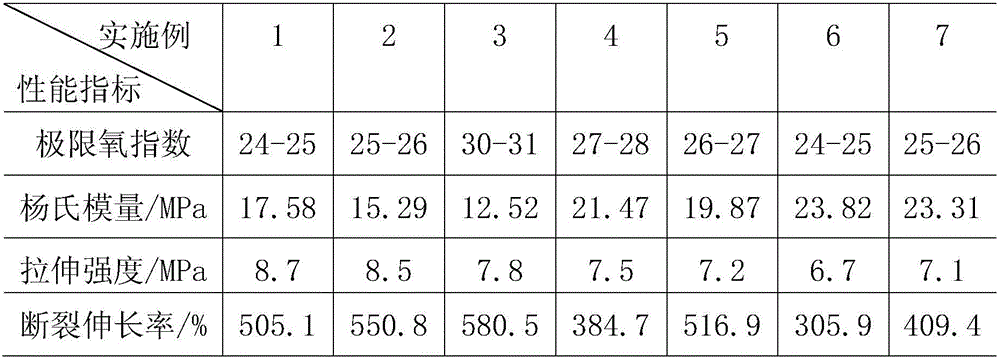

Embodiment 1

[0025] The flame retardant synergist used in Example 1 is the product of the reaction of hexachlorocyclotriphosphazene and 3-aminopropyltriethoxysilane. The preparation method is as follows: first dissolve hexachlorocyclotriphosphazene in tetrahydrofuran, and then Add triethylamine, put it into a clean and dry reaction tube and let it be protected by nitrogen, then add 3-aminopropyltriethoxysilane dropwise, stir the reaction magnetically at 0°C for 4 hours and stop the reaction; The mixture was filtered to remove the insoluble triethylamine hydrochloride, the salt was washed with tetrahydrofuran and the washing solution was incorporated into the filtrate, and the tetrahydrofuran solvent was removed by rotary evaporation to obtain an oily substance. The mixture was washed with ether for 2-3 times, and the solution was rotated. Steam to obtain an oily substance, and finally wash 2-3 times with petroleum ether, and vacuum dry for 24h to obtain an oily product; wherein, the molar ra...

Embodiment 2

[0026] The flame retardant synergist used in Example 2 is the product of the reaction of hexachlorocyclotriphosphazene and 3-aminopropyltriethoxysilane. The preparation method is as follows: first dissolve hexachlorocyclotriphosphazene in tetrahydrofuran, and then Add triethylamine, put it into a clean and dry reaction tube and let it be protected by nitrogen, then add 3-aminopropyltriethoxysilane dropwise, stir the reaction magnetically at 0°C for 4 hours and stop the reaction; The mixture was filtered to remove the insoluble triethylamine hydrochloride, the salt was washed with tetrahydrofuran and the washing solution was incorporated into the filtrate, and the tetrahydrofuran solvent was removed by rotary evaporation to obtain an oily substance. The mixture was washed with ether for 2-3 times, and the solution was rotated. Steam to obtain an oily substance, and finally wash 2-3 times with petroleum ether, and vacuum dry for 24h to obtain an oily product; wherein, the molar ra...

Embodiment 3

[0027] The flame retardant synergist used in Example 3 is the product of the reaction of hexachlorocyclotriphosphazene and 3-aminopropyltriethoxysilane. The preparation method is as follows: first dissolve hexachlorocyclotriphosphazene in tetrahydrofuran, and then Add triethylamine, put it into a clean and dry reaction tube and let it be protected by nitrogen, then add 3-aminopropyltriethoxysilane dropwise, stir the reaction magnetically at 0°C for 4 hours and stop the reaction; The mixture was filtered to remove the insoluble triethylamine hydrochloride, the salt was washed with tetrahydrofuran and the washing solution was incorporated into the filtrate, and the tetrahydrofuran solvent was removed by rotary evaporation to obtain an oily substance. The mixture was washed with ether for 2-3 times, and the solution was rotated. Steam to obtain an oily substance, and finally wash 2-3 times with petroleum ether, and vacuum dry for 24h to obtain an oily product; wherein, the molar ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com