Reactive type flame-retardant epoxy resin curing agent and preparation method thereof

An epoxy resin curing and reactive flame retardant technology is applied in the field of flame retardants to achieve the effects of reduced impact, good application prospect and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

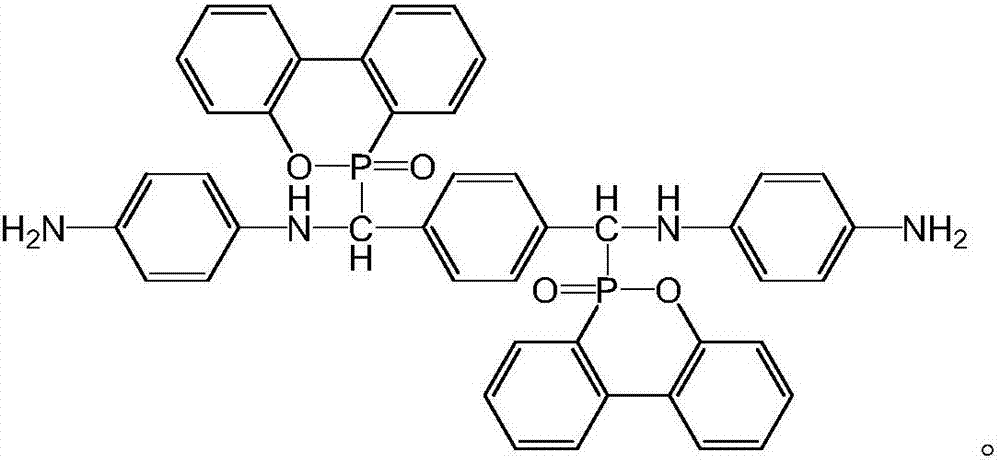

[0024] (1) To a place equipped with a thermometer, condensing reflux, magnetic stirring, dropping funnel and N 2 Add 20mL deionized water and 0.01mol p-phenylenediamine into the 250ml four-necked flask, stir and heat to 95°C to make it completely dissolved, then add 0.05mol terephthalaldehyde dropwise to the flask, under N 2 The reaction was carried out under protective atmosphere for 4h.

[0025] (2) After the reaction is finished, the reaction mixture is placed in a refrigerator for low temperature cooling, and the crude product is obtained by suction filtration. It was dissolved in deionized water and heated, then cooled and recrystallized by the same method, repeated three times, and finally dried in a vacuum oven at 80° C. for 24 hours to obtain an intermediate product.

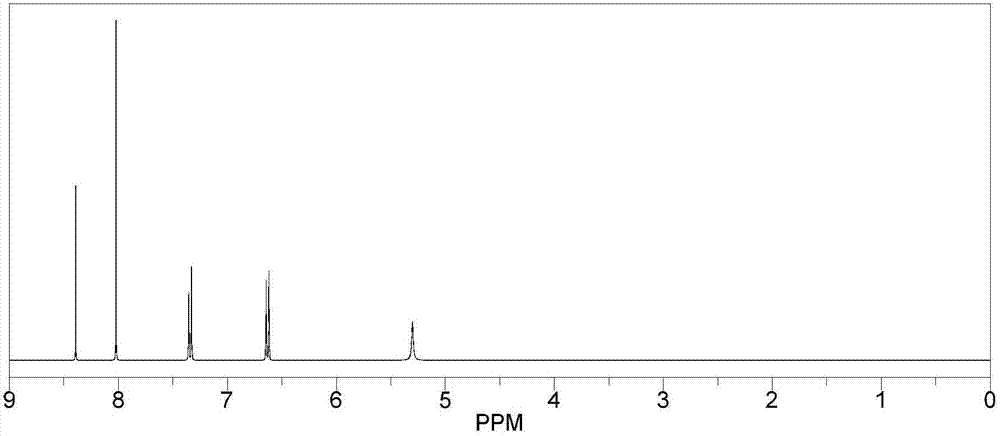

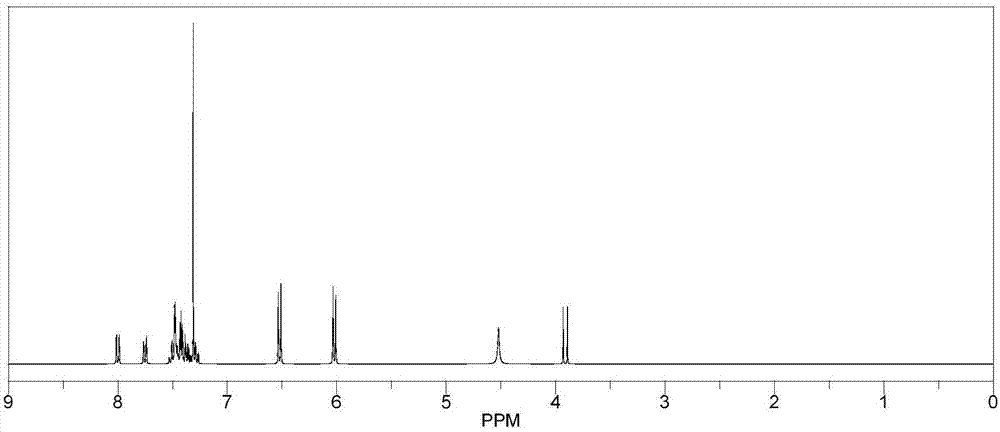

[0026] (3) to a thermometer, condensing reflux, magnetic stirring and N 2 Add 0.02mol DOPO, 0.01mol intermediate product and 10mL DMF into the 250ml three-necked flask that was passed through, and grad...

Embodiment 2

[0030] (1) To a place equipped with a thermometer, condensing reflux, magnetic stirring, dropping funnel and N 2 Add 20mL deionized water and 0.01mol p-phenylenediamine into the 250ml four-neck flask that was passed through, stir and heat to 95°C and make it completely dissolve, then add 0.07mol terephthalaldehyde dropwise to the flask, and in N 2 The reaction was carried out for 4 h under a protective atmosphere, and the intermediate product was obtained by separation and purification.

[0031] (2) to a thermometer, condensing reflux, magnetic stirring and N 2 Add 0.024mol DOPO, 0.01mol intermediate product and 10mL DMF into the 250ml three-neck flask that was passed through, and gradually raise the temperature to dissolve completely. 2 React for 6 hours under protective atmosphere, and obtain a new type of reactive flame-retardant epoxy resin curing agent after separation and purification.

Embodiment 3

[0033] (1) To a place equipped with a thermometer, condensing reflux, magnetic stirring, dropping funnel and N 2 Add 20mL deionized water and 0.01mol p-phenylenediamine into the 250ml four-neck flask that was passed through, stir and heat to 95°C and make it completely dissolve, then add 0.07mol terephthalaldehyde dropwise to the flask, and in N 2 The reaction was carried out for 6 hours under a protective atmosphere, and the intermediate product was obtained by separation and purification.

[0034] (2) to a thermometer, condensing reflux, magnetic stirring and N 2 Add 0.024mol DOPO, 0.01mol intermediate product and 10mL DMF into the 250ml three-necked flask, gradually raise the temperature to make it completely dissolved, at 140℃, N 2 React for 6 hours under protective atmosphere, and obtain a new type of reactive flame-retardant epoxy resin curing agent after separation and purification.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com