Flame-retarding and environment-friendly plastic material and preparation method thereof

A plastic material, environmental protection technology, applied in the field of flame retardant materials, can solve the problems of poor synergy, poor flame retardant performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

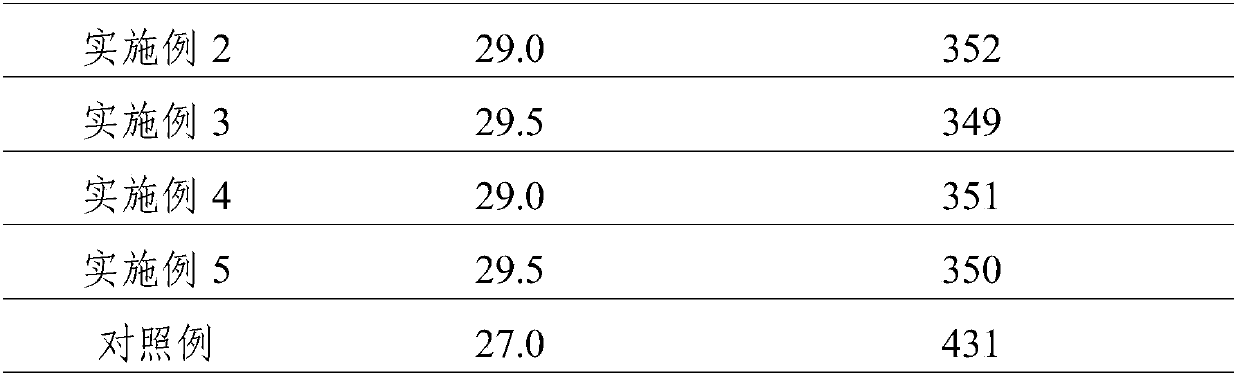

Embodiment 1

[0019] A flame-retardant and environmentally friendly plastic material, characterized in that the plastic material is composed of the following raw materials in parts by weight: 10 parts of nano-silica, 7 parts of ammonium polyphosphate powder, 5 parts of aluminum hypophosphite, 4 parts of polylactic acid, 15 parts Antimony trioxide, 5 parts of 2,3-dichloropropyl ester, 3 parts of aluminum oxide hydrate, 10 parts of bromo-chloroalkyl phosphate diester, 4 parts of EPDM rubber, and 2 parts of dispersing lubricant.

[0020] The preparation method of the plastic material comprises the following steps:

[0021] (1) Mix polylactic acid, aluminum hypophosphite, EPDM rubber and nano-silica, grind it with a high-speed ball mill for 40 minutes until the particle size is 5um, and then add the mixture to an internal mixer at 180°C for internal mixing After 15 minutes, take out the composite material after banburying, and set aside;

Embodiment 2

[0025] A flame-retardant and environmentally friendly plastic material, characterized in that the plastic material is composed of the following raw materials in parts by weight: 15 parts of nano silicon dioxide, 3 parts of ammonium polyphosphate powder, 1 part of aluminum hypophosphite, 9 parts of polylactic acid, 10 parts Antimony trioxide, 2 parts of 2,3-dichloropropyl ester, 7 parts of aluminum oxide hydrate, 6 parts of bromo-chloroalkyl phosphate diester, 1 part of EPDM rubber, 0.5 part of dispersing lubricant.

[0026] The preparation method of the plastic material comprises the following steps:

[0027] (1) Mix polylactic acid, aluminum hypophosphite, EPDM rubber and nano-silica, grind it with a high-speed ball mill for 30 minutes until the particle size is 10um, and then add the mixture to an internal mixer at 180°C for internal mixing After 15 minutes, take out the composite material after banburying, and set aside;

[0028] (2) Add antimony trioxide, 2,3-dichloroprop...

Embodiment 3

[0031] A flame-retardant and environment-friendly plastic material, the plastic material is composed of the following raw materials in parts by weight: 14 parts of nano silicon dioxide, 4 parts of ammonium polyphosphate powder, 4 parts of aluminum hypophosphite, 5 parts of polylactic acid, 14 parts of antimony trioxide , 4 parts of 2,3-dichloropropyl ester, 4 parts of hydrated alumina, 7 parts of bromo-chloroalkyl phosphate diester, 2 parts of EPDM rubber, and 0.6 parts of dispersed lubricant.

[0032] The preparation method of the plastic material comprises the following steps:

[0033] (1) Mix polylactic acid, aluminum hypophosphite, EPDM rubber and nano-silica, grind it with a high-speed ball mill for 35 minutes until the particle size is 6um, and then add the mixture to an internal mixer at 180°C for internal mixing After 15 minutes, take out the composite material after banburying, and set aside;

[0034] (2) Add antimony trioxide, 2,3-dichloropropyl ester, hydrated alum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com