Halogen-free environment-friendly inflaming retarding HIPS (High Impact Polystyrene) material as well as preparation method and application thereof

An environmentally friendly and auxiliary flame retardant technology, applied in the field of halogen-free environmentally friendly flame retardant HIPS materials and their preparation, can solve the problem of no use value, poor material fluidity and impact performance, and unresolved compatibility between flame retardants and resins Problems such as problems, achieve good appearance, improve fluidity, and excellent rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

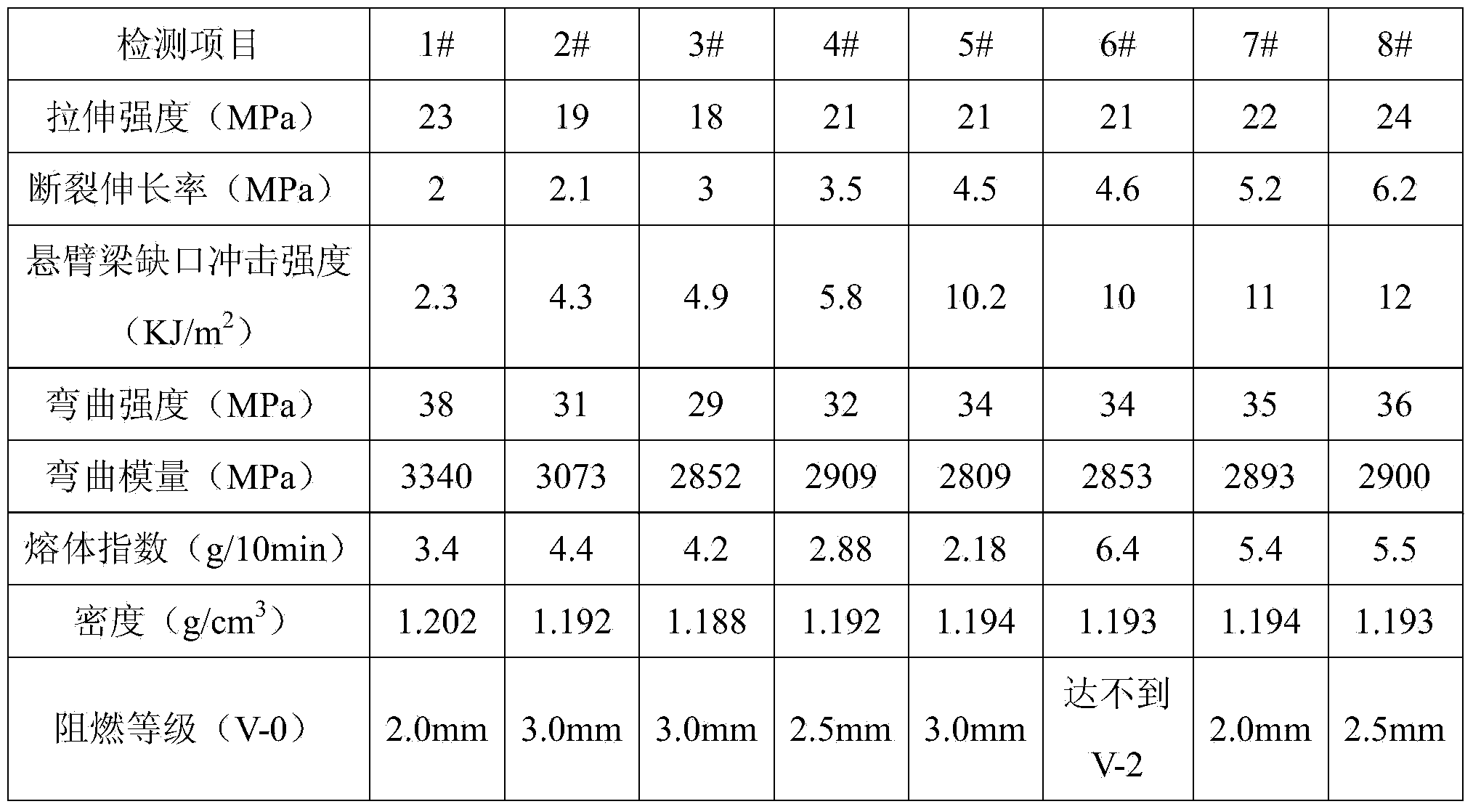

Examples

Embodiment 1

[0045] Example 1: Preparation of halogen-free environmentally friendly flame-retardant HIPS material

[0046] Put 65.8 parts by weight of HIPS514P, 26 parts by weight of aluminum hypophosphite, 6 parts by weight of melamine cyanurate, 1 part by weight of coupling agent JH-A110, 1 part by weight of EBS B50 and 0.2 parts by weight of SN80-SA7 into the high-speed Mix at high speed in the mixer for 3 minutes to obtain the mixed material, and then transport the mixed material to the twin-screw extruder through a precisely metered feeding device. The length-to-diameter ratio of the extruder is 30, and the screw speed is 300 rpm. Under the shearing, mixing, and conveying of the screw, the material can be fully melted, mixed, and then extruded, granulated, and dried to obtain halogen-free environmentally friendly flame-retardant HIPS material.

Embodiment 2

[0047] Example 2: Preparation of halogen-free environmentally friendly flame-retardant HIPS material

[0048] The HIPS514P of 63.4 parts by weight, the aluminum hypophosphite of 26 parts by weight, the melamine cyanurate of 6 parts by weight, the dipentaerythritol of 3 parts by weight, the SBS of 2 parts by weight, the JH-A110 of 1 part by weight, the EBS B50 of 1 part by weight and 0.2 parts by weight of SN80-SA7 are put into a high-speed mixer and mixed at high speed for 3 minutes to obtain a mixed material, and then the mixed material is transported to a twin-screw extruder through a precisely metered feeding device, and the temperature of each section of the extruder screw is controlled at Between 170 and 220°C, the length-to-diameter ratio of the twin-screw extruder is 30, and the screw speed is 300 rpm. Under the shearing, mixing, and conveying of the screw, the material is fully melted, mixed, and then extruded. Granulate and dry to obtain halogen-free, environmentally fr...

Embodiment 3

[0049] Example 3: Preparation of halogen-free environmentally friendly flame-retardant HIPS material

[0050] Put 26 parts by weight of aluminum hypophosphite into the high-speed pre-mixer and stir for 5-15 minutes. Under high-speed stirring, spray 1 part by weight of JH-A110 in the form of mist, continue stirring for 5 minutes, and then put it in the kneader at 78- Kneading reaction at 112°C for 2 hours; then with 62.4 parts by weight of HIPS514P, 6 parts by weight of melamine cyanurate, 3 parts by weight of dipentaerythritol, 3 parts by weight of SBS, 1 part by weight of EBS B50 and 0.2 parts by weight of SN80- Put SA7 into the high-speed mixer and mix at high speed for 6 minutes to obtain the mixed material, and then transport the mixed material to the twin-screw extruder through a precisely metered feeding device. The temperature of each section of the extruder screw is controlled between 170 and 220 °C The length-to-diameter ratio of the twin-screw extruder is 35, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com