Halogen-free flame-retardant polypropylene composite cable material and preparation method thereof

A technology of flame retardant polypropylene and composite cable material, applied in the field of modified polypropylene, can solve the problem of insignificant flame retardant effect, achieve good mechanical properties, excellent flame retardant performance, and improve the effect of limiting anaerobic index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

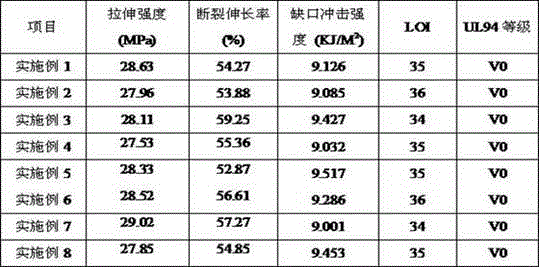

Examples

Embodiment 1

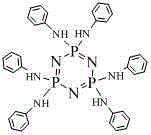

[0025] Accurately weigh 100 parts by weight of polypropylene powder, 5 parts by weight of hexaphenylaminocyclotriphosphazene, 50 parts by weight of magnesium hydroxide, 10 parts by weight of ethylene-vinyl acetate copolymer, 20 parts by weight of maleic anhydride grafted polypropylene, 0.2 parts by weight of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester was stirred in a high-speed mixer for 5 minutes, and mixed uniformly to obtain a premix. The premix is melt-extruded on a twin-screw extruder, water-cooled, pelletized, and dried. The rotation speed of the screw machine was 300 rpm, and the temperature was 185° C. to obtain halogen-free flame-retardant polypropylene pellets.

Embodiment 2

[0027] Accurately weigh 100 parts by weight of polypropylene powder, 10 parts by weight of hexaphenylaminocyclotriphosphazene, 50 parts by weight of magnesium hydroxide, 10 parts by weight of EPDM, 20 parts by weight of maleic anhydride grafted polypropylene, double 0.2 parts by weight of (2.4-di-tert-butylphenyl) pentaerythritol bis-diphosphite was stirred in a high-speed mixer for 5 minutes, and mixed uniformly to obtain a premix. The premix is melt-extruded on a twin-screw extruder, water-cooled, pelletized, and dried. The rotation speed of the screw machine was 300 rpm, and the temperature was 185° C. to obtain halogen-free flame-retardant polypropylene pellets.

Embodiment 3

[0029] Accurately weigh 100 parts by weight of polypropylene powder, 4 parts by weight of hexaphenylaminocyclotriphosphazene, 50 parts by weight of magnesium hydroxide, 10 parts by weight of methyl methacrylate-butadiene-styrene copolymer, maleic anhydride 20 parts by weight of grafted polypropylene, 0.2 parts by weight of tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester were stirred in a high-speed mixer for 5 minutes, and mixed uniformly to obtain the mixture. The premix is melt-extruded on a twin-screw extruder, water-cooled, pelletized, and dried. The rotation speed of the screw machine was 300 rpm, and the temperature was 185° C. to obtain halogen-free flame-retardant polypropylene pellets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com