Phosphorus series non-halogen composite flame retardant for polyolefin, preparation method thereof and flame retardant polyolefin

A compound flame retardant and polyolefin technology, applied in the field of flame retardants, can solve the problems of complex treatment process, loss of fluidity, large addition amount, etc., and achieve the effect of small dosage, improved red phosphorus dispersibility, and small addition amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

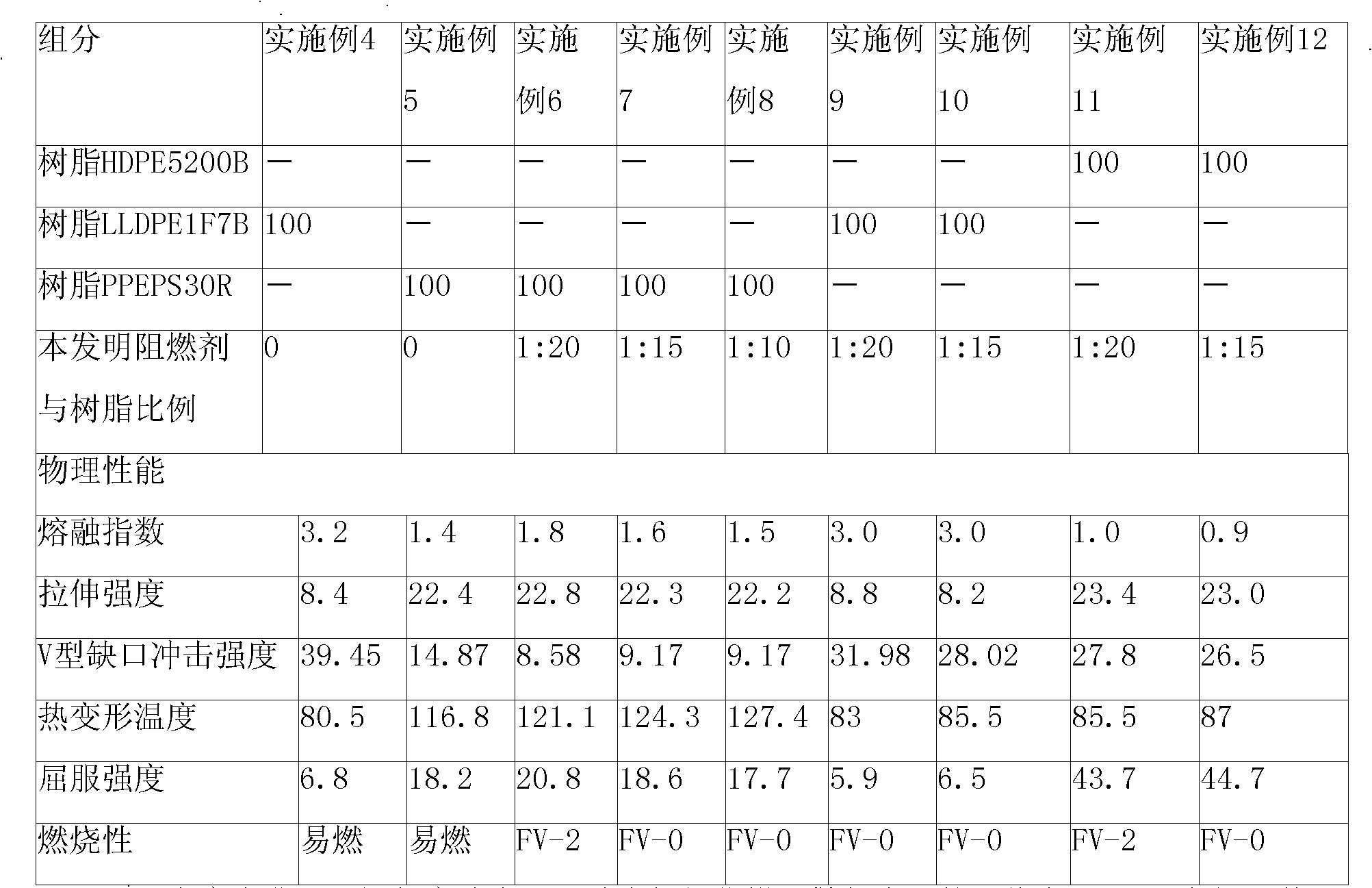

Examples

Embodiment 1

[0020] Embodiment 1: Raw materials: 800 grams of modified red phosphorus, 200 grams of nano-magnesium hydroxide, 162.8 grams of polyethylene-vinyl acetate copolymer emulsion, 24 grams of comonomer diethylene glycol acrylate, free radical initiator ammonium persulfate 4 gram

[0021]Preparation method of flame retardant: Take modified red phosphorus and polyethylene-vinyl acetate copolymer emulsion, add water and mix evenly, place in colloid mill, and shear under the conditions of grinding disc line speed > 30m / s and rotation speed 3000-3500r / min Grind for 15 minutes, add nano-magnesium hydroxide, diethylene glycol acrylate comonomer, free radical initiator ammonium persulfate, react for 30 minutes under grinding conditions, discharge, and dry to obtain 1053 grams of flame retardant, P The content is 71%.

Embodiment 2

[0022] Embodiment 2: Raw materials: 1000 grams of modified red phosphorus, 300 grams of nano aluminum hydroxide, 200 grams of pure acrylic copolymer emulsion, 24 grams of comonomer vinyl acetate, 4 grams of free radical initiator potassium persulfate

[0023] Flame retardant preparation method: Take modified red phosphorus and pure acrylic copolymer emulsion, add water and mix evenly, place in a ball mill, shear and grind for 20 minutes under the conditions of milling disc line speed > 30m / s, rotation speed 3000-3500r / min, Add nano-aluminum hydroxide, vinyl acetate comonomer, and free radical initiator potassium persulfate, react for 30 minutes under grinding conditions, discharge, and dry to obtain the flame retardant of the present invention. After drying, 1046 grams of flame retardant were obtained, and the P content was 72%.

Embodiment 3

[0024] Embodiment 3: Raw materials: 800 grams of modified red phosphorus, 162.8 grams of pure acrylic emulsion, 100 grams of nanometer magnesium hydroxide, 100 grams of nanometer aluminum hydroxide, 24 grams of comonomer methacrylic acid, free radical initiator ammonium persulfate 4 gram

[0025] Flame retardant preparation method: Take modified red phosphorus and pure acrylic copolymer emulsion, add water and mix evenly, place in a colloid mill, and shear and grind for 10 minutes under the conditions of milling disc line speed > 30m / s and rotational speed 3000-3500r / min , add nano-magnesium hydroxide, nano-aluminum hydroxide, methacrylic acid comonomer, free radical initiator ammonium persulfate, react under grinding conditions for 30 minutes, discharge, and dry to obtain 1036 grams of flame retardant, p content 70%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com