Self-inflaming-retarding epoxy resin curing agent containing phosphorus-nitrogen and preparation method thereof

An epoxy resin curing and solvent technology, which is applied in the field of phosphorus and nitrogen-containing self-flame retardant epoxy resin curing agent and its preparation, can solve the problems of complex operation, poor processability, easy decomposition and loss, etc., and achieve high reactivity, relative Good capacitance and easy commercial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Synthesis of intermediates

[0031] Add N-phenyl-1,4-phenylenediamine (18.424g, 0.1mol), 4-hydroxybenzaldehyde (12.212g, 0.1mol) and 100ml ethanol in a 250ml three-necked flask equipped with a condenser and a stirrer Solvent, at room temperature, react for 4h, filter the reaction system with filter paper, wash the filtered solid with ethanol solvent 4 times, put it in a vacuum oven to heat up (50°C) and dry to obtain 27.96g of a green solid product, which is an intermediate, The yield is 91.27%.

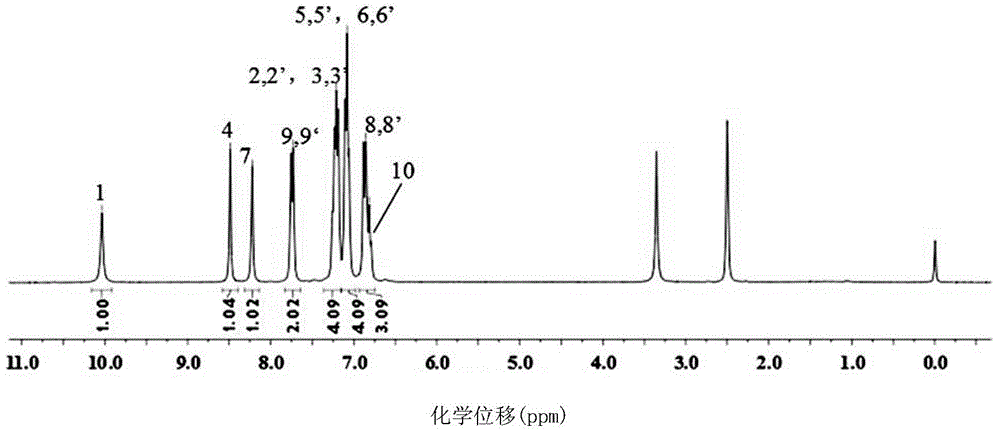

[0032] 2) Synthesis of curing agent DOPO-RT

[0033] The intermediate (14.418g, 0.05mol) that above-mentioned reaction gains, DOPO (10.8g, 0.05mol) and 100ml dimethylformamide (DMF) solvent join in the 250ml container that is equipped with condenser tube and stirrer to stir, in At room temperature, react for 6 hours, filter the reaction system with filter paper, wash the filtrate several times with ethanol, put it in a vacuum oven (50°C) and dry it to obtain 23.58g of whi...

Embodiment 2

[0035] 1) Synthesis of intermediates

[0036] Add N-phenyl-1,4-phenylenediamine (22.1088g, 0.12mol), 4-hydroxybenzaldehyde (12.212g, 0.1mol) and 100ml ethanol in a 250ml three-necked flask equipped with a condenser and a stirrer Solvent, react at room temperature for 3 hours, filter the reaction system with filter paper, wash the filtered solid with ethanol solvent 4 times, put it in a vacuum oven to heat up (35°C) and dry it to obtain 31.21g of a green solid product, which is an intermediate, The yield reached 90.94%.

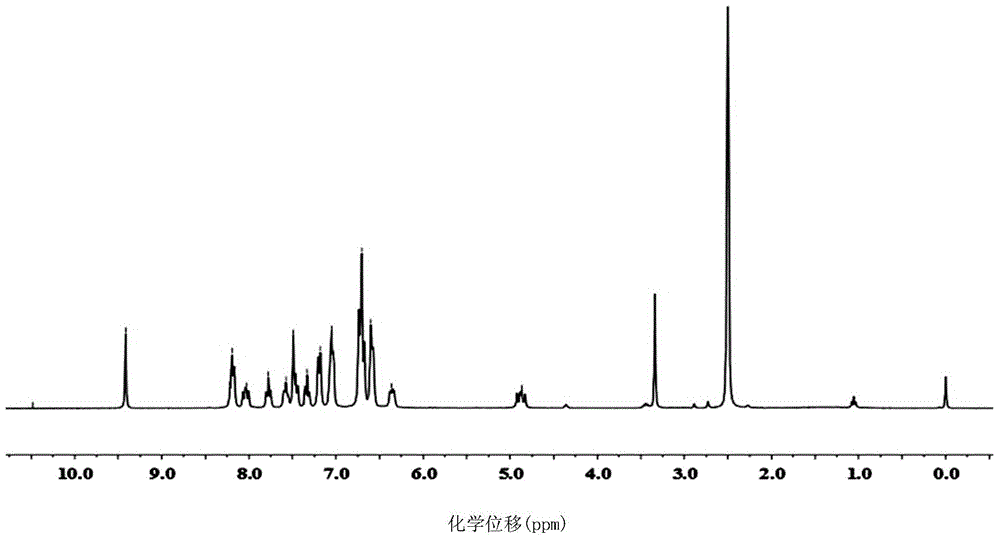

[0037] 2) Synthesis of curing agent DOPO-RT

[0038] The intermediate (14.418g, 0.05mol) obtained by the above reaction, DOPO (12.96g, 0.05mol) and 100ml of dimethylformamide (DMF) solvent were added to the 250ml container that was equipped with a condenser tube and a stirrer to stir. At room temperature, react for 5 hours, filter the reaction system with filter paper, wash the filtrate several times with ethanol, put it in a vacuum oven (35°C) and dry it to...

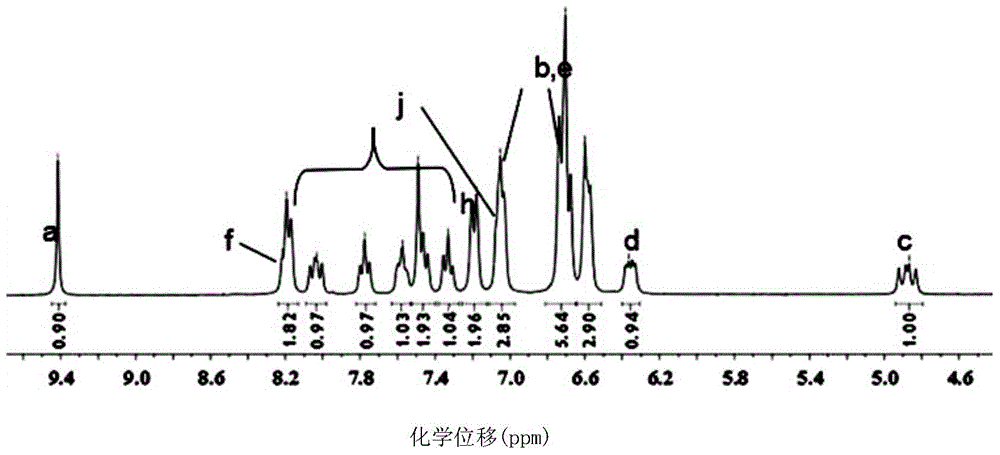

Embodiment 3

[0040]Add N-phenyl-1,4-phenylenediamine (20.2664g, 0.11mol), 4-hydroxybenzaldehyde (12.212g, 0.1mol), DOPO (21.6g, 0.1mol) and 150ml dimethylformamide (DMF) solvent, react at room temperature for 8h, filter the reaction system with filter paper, wash the filtrate 3 times with methanol, put it into a vacuum oven to heat up (40°C ) was dried to obtain 54.0784 g of a white solid product with a yield of 91.29%, which was the flame retardant curing agent DOPO-RT.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com