Middle-low molecular weight brominated multi-block copolymer flame retardant and solution three-step preparation method thereof

A multi-block copolymer, low molecular weight technology, applied in the field of polymer flame retardants, can solve the problems of no multi-block structure, single structure, low bromine content, etc., to achieve easy uniform dispersion, less dosage, bromine The effect of high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

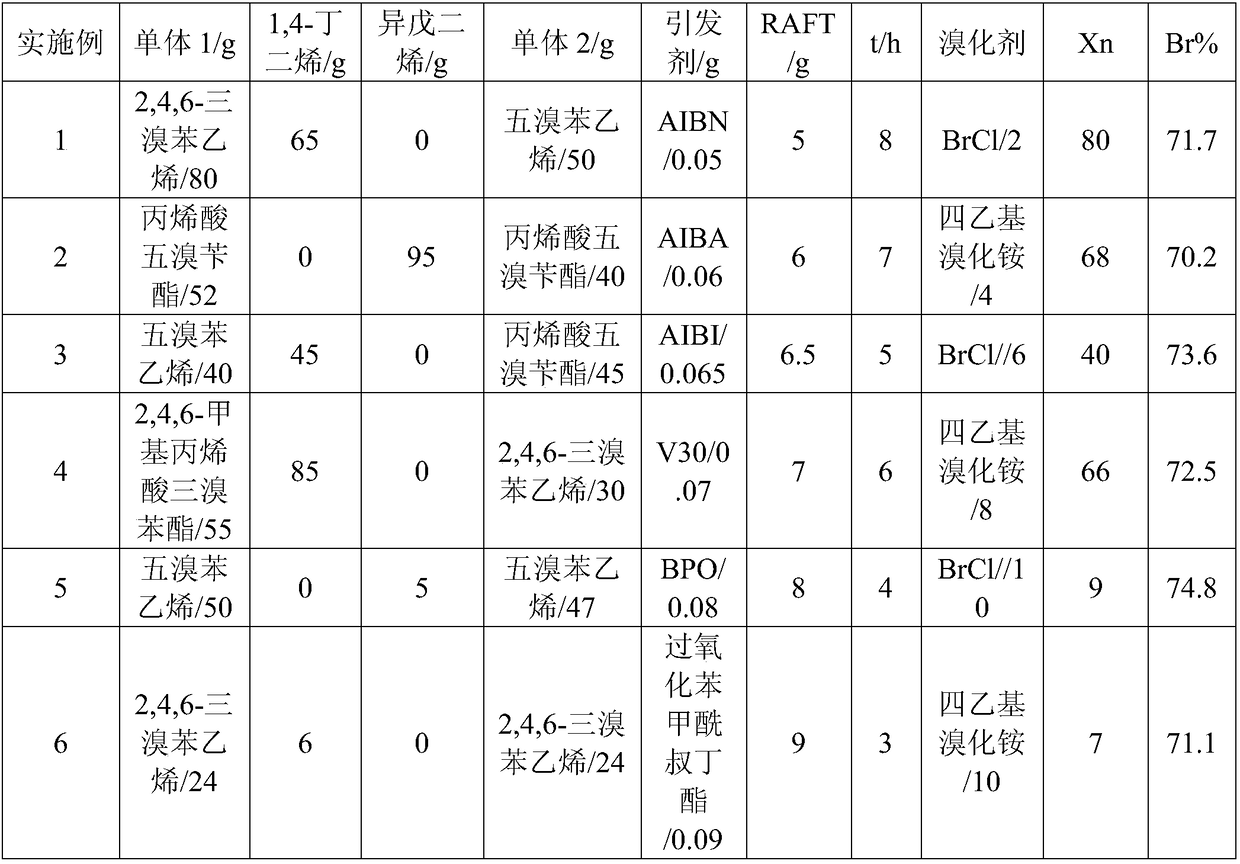

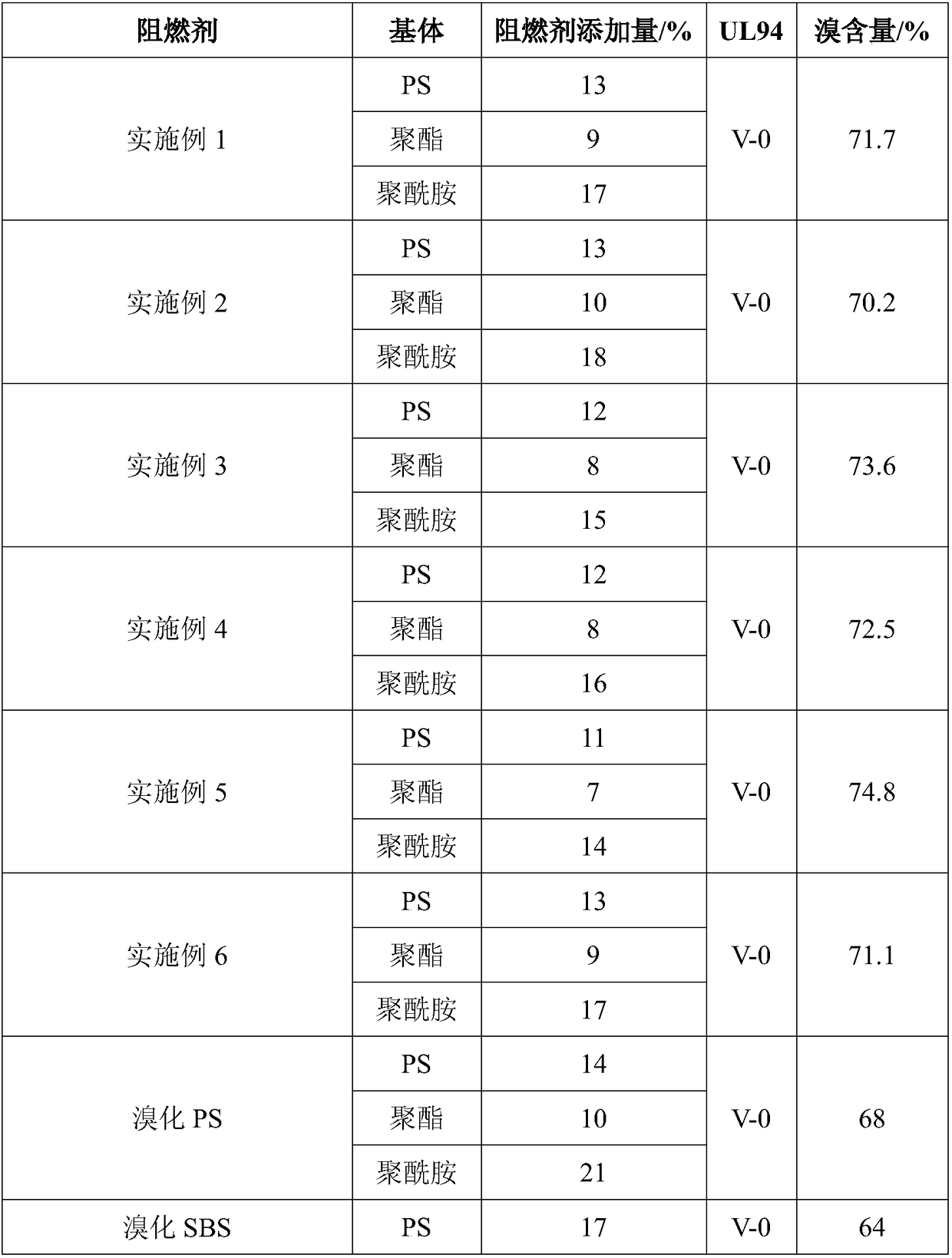

Examples

Embodiment 1

[0043] Embodiment 1, a kind of preparation method of medium and low molecular weight brominated polymer flame retardant:

[0044] 1. Using 2,4,6-tribromostyrene, 1,4-butadiene, and pentabromostyrene as polymerization monomers, azobisisobutyronitrile (AIBN) as an initiator, and 4-cyano-4 -(thiobenzoyl) valeric acid is a chain transfer agent, and obtains medium and low molecular weight brominated styrene-butadiene-brominated styrene triblock copolymers by three-step polymerization, and the steps are as follows:

[0045] (1), 80 grams of 2,4,6-tribromostyrene, 0.05 grams of azobisisobutyronitrile (AIBN), 5 grams of 4-cyano-4-(thiobenzoyl) valeric acid, 200ml as Tetrahydrofuran (THF) as a solvent was added to the reactor, and reacted at 60°C for 8 hours under the protection of nitrogen to obtain a brominated styrene homopolymer with a degree of polymerization of 12 and a molecular weight of 4092=12*341;

[0046] Remarks: The molecular weight is measured by GPC, and then the degre...

Embodiment 2

[0051] Embodiment 2, a kind of preparation method of medium and low molecular weight brominated polymer flame retardant:

[0052] 1. With pentabromobenzyl acrylate and isoprene as polymerized monomers, azobisisobutylamidine hydrochloride (AIBA) as initiator, and S-(thiobenzoyl) mercaptoacetic acid as chain transfer agent, Obtain medium and low molecular weight brominated acrylate-isoprene-brominated acrylate triblock copolymer by three-step polymerization, the steps are as follows:

[0053] (1), 52 grams of pentabromobenzyl acrylate, 0.06 grams of azobisisobutylamidine hydrochloride (AIBA), 6 grams of S-(thiobenzoyl) mercaptoacetic acid, and 200 ml of toluene as a solvent are added to the reaction kettle , under the protection of nitrogen, react at 65°C for 7 hours to obtain a brominated acrylate homopolymer with a degree of polymerization of 4, and a molecular weight of 2228=4*557;

[0054] (2), 95 grams of isoprene was added to the above-mentioned reaction kettle under the ...

Embodiment 3

[0058] Embodiment 3, a kind of preparation method of medium and low molecular weight brominated polymer flame retardant:

[0059] 1. Using pentabromobenzyl acrylate, 1,4-butadiene and pentabromostyrene as polymerization monomers, azobisisobutylimidazoline hydrochloride (AIBI) as initiator, phenyldithioacetic acid- 1-Phenylethyl ester is a chain transfer agent, and the medium and low molecular weight brominated styrene-butadiene-brominated acrylate triblock copolymer is obtained by three-step polymerization, and the steps are as follows:

[0060] (1), 40 grams of pentabromostyrene, 0.065 grams of azobisisobutylimidazoline hydrochloride (AIBI), 6.5 grams of phenyldithioacetic acid-1-phenylethyl ester, and 200ml of solvent xylene are added to the reactor , under the protection of nitrogen, react at 70°C for 5 hours to obtain a brominated styrene homopolymer with a degree of polymerization of 3, and a molecular weight of 1497=3*499;

[0061] (2) Add 45 grams of 1,4-butadiene into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com