Efficient seawater desalination and comprehensive utilization method

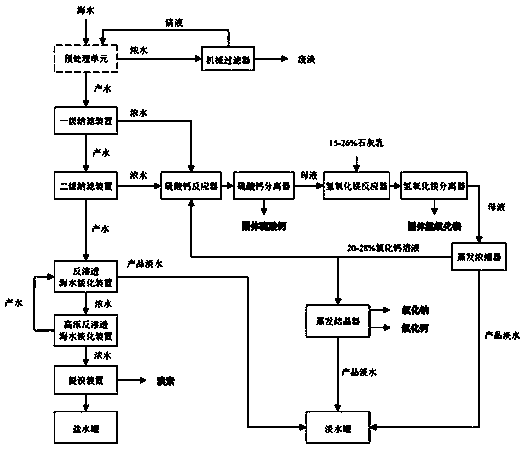

A seawater, high-efficiency technology, applied in chemical instruments and methods, seawater treatment, general water supply conservation, etc., can solve problems such as high concentration of divalent ions, high risk of scaling, difficult operation and maintenance, etc., to reduce concentrated water discharge, The improvement of comprehensive utilization rate and the effect of improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] For a seawater desalination system with a daily output of 10,000 cubic meters of fresh water, the typical composition of seawater is as follows:

[0034] Element K +

Na +

Ca 2+

Mg 2+

Sr 2+

Cl -

SO 4 2-

HCO 3 -

F -

Br -

mg / L 399 10770 412 1290 7.9 19354 2714 142 1.3 67.3

[0035] The original sea water intake is 570m 3 / h, after electrolytic chlorine production and sterilization, it enters coagulation sedimentation for preliminary purification to remove fine suspended particles or colloids, and then further removes fine suspended particles, colloids, microorganisms, organic matter and other impurities in seawater through sand filtration and ultrafiltration, Reduce the turbidity of seawater to less than 1NTU; the concentrated water discharged from coagulation sedimentation, sand filtration and ultrafiltration is mixed and filtered through a filter press, and the solid residue is pressed and...

Embodiment 2

[0041] For a seawater desalination system with a daily output of 10,000 cubic meters of fresh water, the typical composition of seawater is as follows:

[0042] Element K +

Na +

Ca 2+

Mg 2+

Sr 2+

Cl -

SO 4 2-

HCO 3 -

F -

Br -

mg / L 278 10212 641 1637 7.9 19978 3011 263 1.3 56.4

[0043] The original sea water intake is 600m 3 / h, after being sterilized by chlorine dioxide, it enters the air flotation device for preliminary purification to remove fine suspended particles or colloids, and then further removes fine suspended particles, colloids, microorganisms and organic matter in seawater through self-cleaning filters and ultrafiltration devices reduce the turbidity of seawater to less than 1.2NTU; the concentrated water discharged from air flotation and ultrafiltration is mixed and filtered through a filter press, and the solid residue is pressed and incinerated harmlessly, and the filtered clear...

Embodiment 3

[0049] For a seawater desalination system with a daily output of 10,000 cubic meters of fresh water, the typical composition of seawater is as follows:

[0050] Element K +

Na +

Ca 2+

Mg 2+

Sr 2+

Cl -

SO 4 2-

HCO 3 -

F -

Br -

mg / L 325 10267 605 1443 7.7 19009.4 3111 263 1.2 58.9

[0051] The original sea water intake is 590m 3 / h, after electrolytic chlorine production and sterilization, it enters coagulation sedimentation for preliminary purification to remove fine suspended particles or colloids, and then further removes fine suspended particles, colloids, microorganisms and organic matter in seawater through fiber bundle filters and ultrafiltration devices reduce the turbidity of seawater to less than 1NTU; the concentrated water discharged from the coagulation sedimentation, fiber bundle filter and ultrafiltration is mixed and filtered through the filter press, the solid residue is pressed an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com