Production method of brominated lignin

A production method and lignin technology, applied in the field of brominated lignin, can solve the problems of large-scale application limitations, poor flame retardancy, low glass transition temperature, etc., achieve low solvent recovery costs, increase bromine content, and heat resistance Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

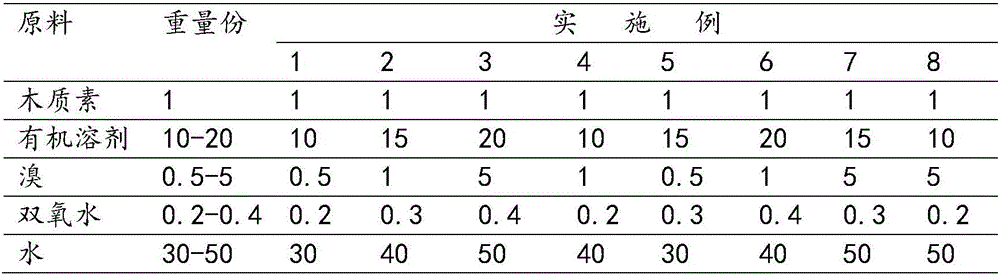

[0016] Embodiment 1 (corresponding example raw material and proportioning value thereof in comparison table 1): 1 part of lignin is added to reactor, then add 10 parts of organic solvent, stir 2-6 hour, then add 0.5 part of bromine, 0.2 part of hydrogen peroxide, Stir at 30-40°C for 1 hour, pour the above reactant into a water tank filled with 30 parts of water and stir to precipitate brominated lignin, centrifuge and separate the precipitate, and dry to obtain a brominated lignin product with a bromine content of 19%. .

Embodiment 2

[0017] Embodiment 2 (corresponding embodiment raw material and proportioning value thereof in comparison table 1): 1 part of lignin is added to reactor, then add 15 parts of organic solvents, stir 2-6 hour, then add 1 part of bromine, 0.3 part of hydrogen peroxide, Stir at 30-40°C for 1 hour, pour the above reactant into a water tank with 40 parts of water and stir to precipitate the brominated lignin, centrifuge the precipitate, dry it, and obtain a brominated lignin product with a bromine content of 27%. .

Embodiment 3

[0018] Embodiment 3 (corresponding embodiment raw material and proportioning value thereof in comparison table 1): 1 part of lignin is added to reaction kettle, then add 20 parts of organic solvents, stir for 2-6 hours, then add 5 parts of bromine, 0.4 part of hydrogen peroxide, Stir at 30-40°C for 1 hour, pour the above reactant into a water tank filled with 50 parts of water and stir to precipitate brominated lignin, centrifuge and separate the precipitate, and dry to obtain a brominated lignin product with a bromine content of 42%. .

[0019] The rest of Examples 4-8 are prepared in the same way as Example 1 with reference to the raw materials and proportioning values of the corresponding examples in Table 1, among which Examples 1-3 are preferred.

[0020] Lignin reacts with bromine, and bromine can be introduced at the α-position, β-position and the ortho- and para-position of the benzene ring, and the combination of bromine and lignin is stable. Utilizing this princip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com