Environment-friendly inflaming-retarding acrylonitrile-butadiene-styrene (ABS) material

An ABS material, an environmentally friendly technology, applied in the field of polymer materials, can solve problems such as human body and environmental pollution, achieve high bromine content, excellent mechanical effects, and reduce black smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

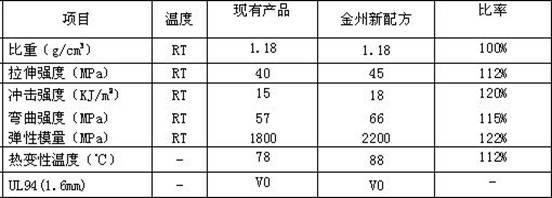

Image

Examples

Embodiment 1

[0031] ABS 79 parts, flame retardant tribromophenol isocyanate 15 parts, flame retardant synergist antimony trioxide 6 parts, antioxidant 1010 0.6 parts, antioxidant 168 0.6 parts, processing aid calcium stearate 0.6 parts, Add it to the high mixer one by one, mix thoroughly for 5-15 minutes, put it into the twin-screw extruder to mix and melt, and then make standard test pieces to test the flame retardancy and mechanical properties.

[0032] In embodiment 1, the flame retardant adopts one of decabromodiphenylethane, tribromophenol isocyanate, triphenyl phosphate, trimethyl phosphate and melamine urate; the flame retardant synergist adopts antimony trioxide, One of zinc borate and ammonium molybdate; the antioxidant uses antioxidant 1010, antioxidant 1330, antioxidant 1076, antioxidant 1034, antioxidant 168, antioxidant 618, antioxidant 300, One of the antioxidant DSTP and antioxidant DMTDP; the processing aid is one of calcium stearate, magnesium stearate, zinc stearate, olei...

Embodiment 2

[0035] ABS 65 parts, flame retardant tribromophenol isocyanate 30 parts, flame retardant synergist antimony trioxide 5 parts, flame retardant synergist zinc borate 5 parts, antioxidant 1330 0.2 parts, antioxidant 1034 0.3 parts, 0.6 parts of magnesium stearate as a processing aid and 0.6 parts of polyethylene wax as a processing aid were sequentially added to the high mixer, mixed thoroughly for 5-15 minutes, put into a twin-screw extruder for mixing and melting, and then made standard test pieces for resistance Flammability and mechanical performance tests.

[0036]

Embodiment 3

[0038] ABS 50 parts, flame retardant decabromodiphenylethane, tribromophenol isocyanate, triphenyl phosphate, trimethyl phosphate and melamine urate total 20 parts, flame retardant synergist antimony trioxide, zinc borate and molybdenum A total of 15 parts of ammonium acid, antioxidant 1010, antioxidant 1330, antioxidant 1076, antioxidant 1034, antioxidant 168, antioxidant 618, antioxidant 300, antioxidant DSTP and antioxidant DMTDP A total of 0.8 parts, a total of 2 parts of processing aids calcium stearate, magnesium stearate, zinc stearate, oleic acid amide, polyethylene wax and siloxane, were added to the high mixer in sequence, and mixed thoroughly for 5-15 minutes Finally, put it into a twin-screw extruder for mixing and melting, and then make a standard test piece to test the flame retardancy and mechanical properties.

[0039]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com