Concrete outer wall heat insulation structure

A technology for external wall insulation and concrete walls, applied in the direction of insulation, building components, building structures, etc., can solve problems such as easy damage to products, difficulty in guaranteeing construction quality, and unreliable pasting of insulation materials, so as to achieve the goal of not being easily damaged and guaranteed Durability and the effect of reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is realized in the following manner:

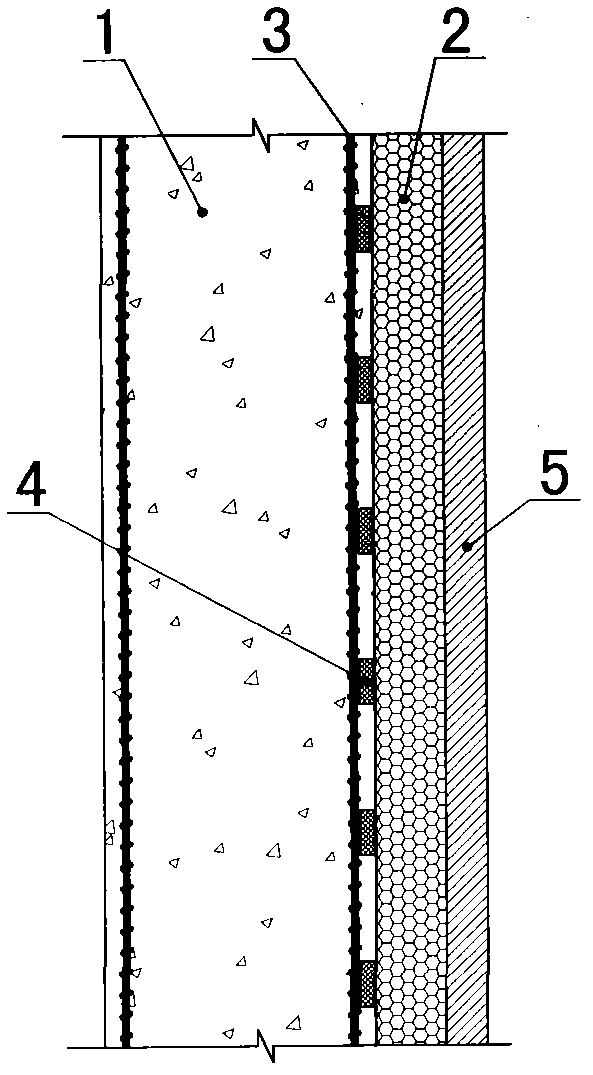

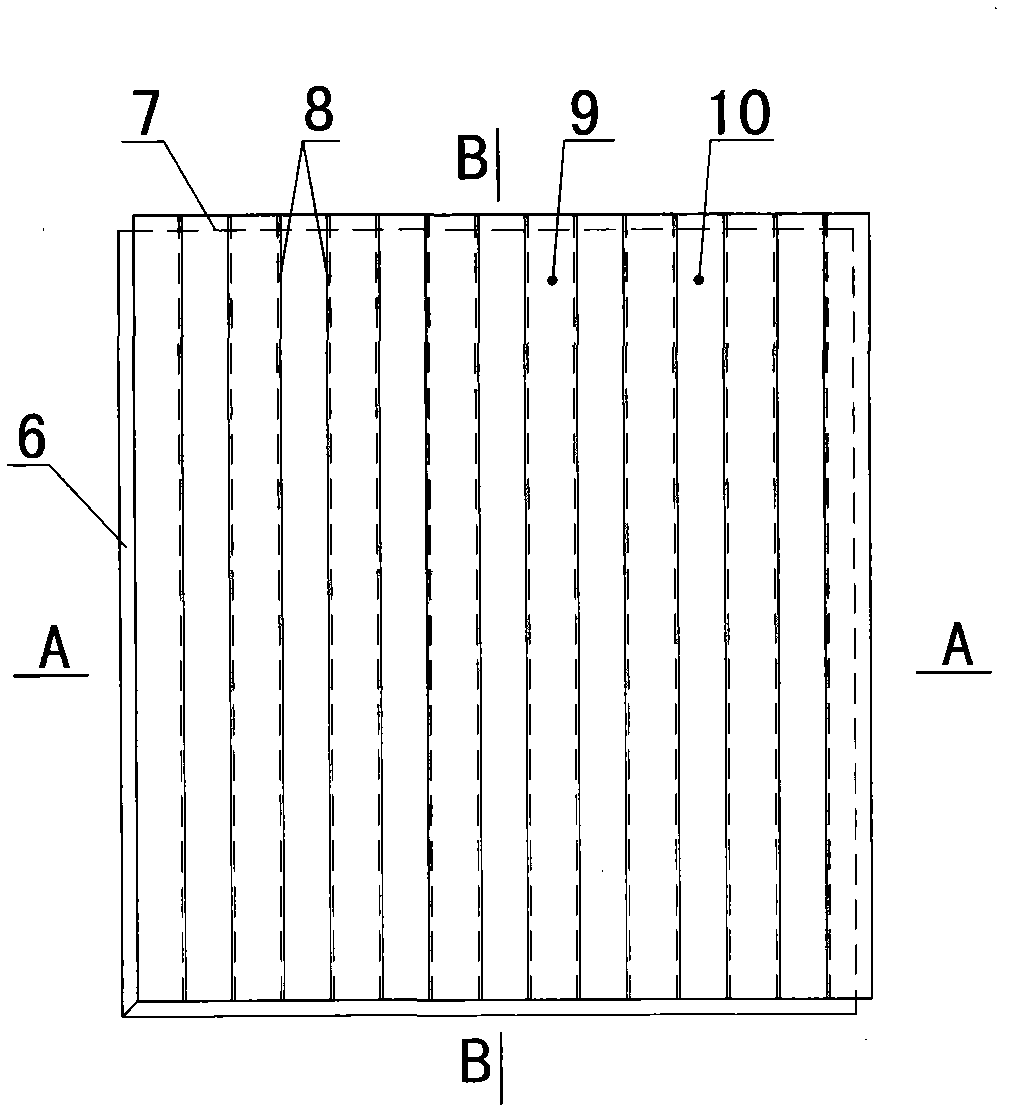

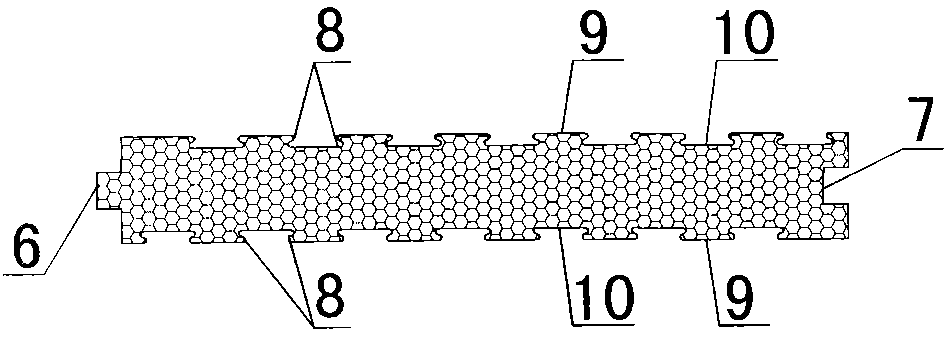

[0030] exist Figure 1-Figure 7 In the shown embodiment, a concrete exterior wall thermal insulation structure includes concrete wall (1), exterior wall reinforcement (3), isolation spacer (4), thermal insulation module (2) and exterior decoration layer ( 5), the corresponding two sides of the four sides of the sheet-shaped thermal insulation module (2) are respectively provided with a tenon (6) and a groove (7), and the tenon (6) and the groove (7) match each other, and the outer An isolation spacer (4) is installed between the wall reinforcement (3) and the thermal insulation module (2), and it is characterized in that the front and back of the thermal insulation module (2) are provided with tie grooves (8), and the tie grooves (8) traverse The width b1 of the notch in the surface is smaller than the width b2 of the bottom of the groove, and the gap between the side wall surface (9) and the bottom (10) of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com