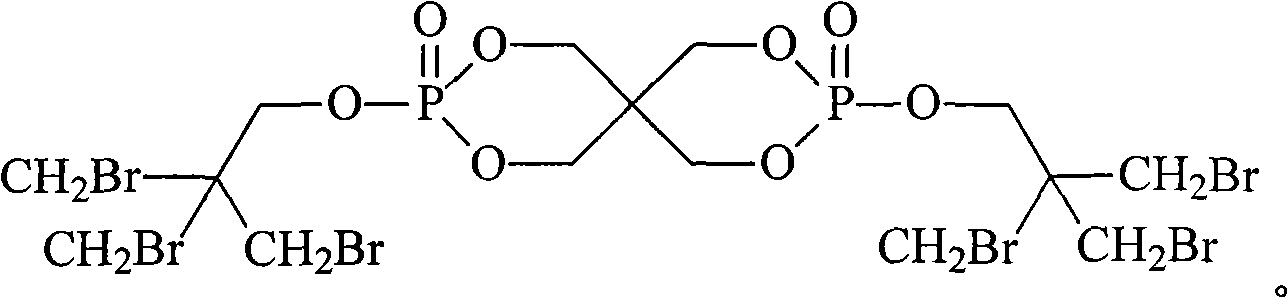

Bromine-containing pentaerythritol phosphoester retardant and preparation method thereof

A technology of bromopentaerythritol phosphate and pentaerythritol, which is applied in the field of bromopentaerythritol-containing phosphate flame retardant and its synthesis process, can solve the problems of low bromine content of flame retardants, great negative impact on PP mechanical properties, and large addition amount , to achieve the effect of improving moisture absorption performance, good anti-ultraviolet performance and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

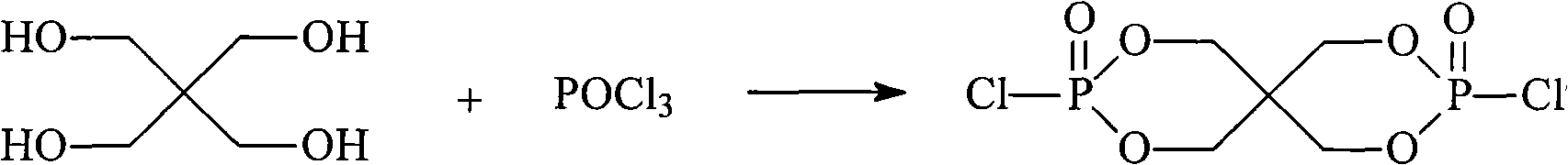

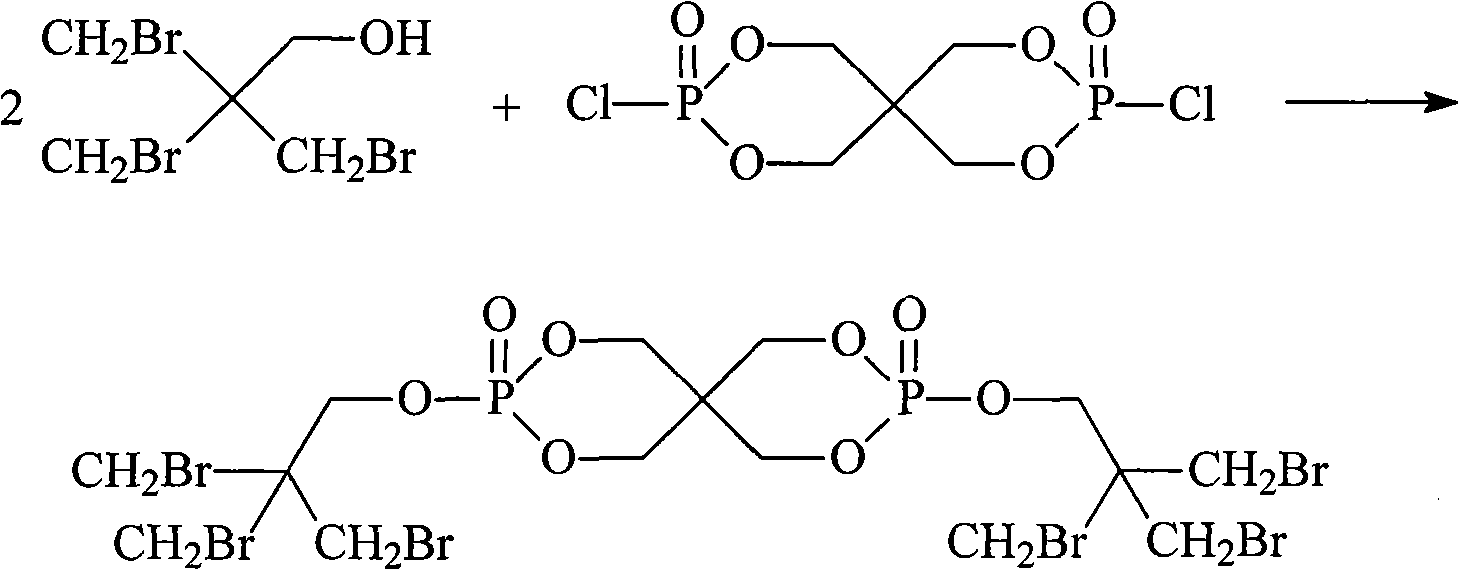

Embodiment 1

[0024] Put pentaerythritol and phosphorus oxychloride in a molar ratio of 1:3 into a reaction vessel equipped with a stirrer and an exhaust gas absorption device, turn on the nitrogen protection, stir at 58°C for 1 hour, then raise the temperature to 103°C and reflux for 9 hours. After reaction finishes, excess phosphorus oxychloride is distilled out under reduced pressure, treats that in container without phosphorus oxychloride existence, add the N-methyl-N-propenyl morpholine quaternary ammonium ion of 100 milliliters / mole pentaerythritol in container liquid and tribromoneopentyl alcohol (the molar ratio of pentaerythritol to pentaerythritol is 1.5:1), start stirring, and heat to reflux at 80° C. for 4 hours under the protection of nitrogen. After the reaction, cool down to room temperature with water at 0°C, rinse twice with toluene, and then rinse twice with distilled water until the product has no odor of phosphorus oxychloride, toluene, etc., and dry for 2 hours to obtain...

Embodiment 2

[0026] Similar to Example 1, put pentaerythritol and phosphorus oxychloride in a molar ratio of 1:10 into a reaction vessel equipped with a stirrer and an exhaust gas absorption device, turn on nitrogen protection, stir at 62°C for 1.5 hours, and then heat up to 107°C Reflux for 11 hours. After the reaction is over, distill off excess phosphorus oxychloride under reduced pressure. After there is no liquid in the container, control the temperature of the system at 75°C, slowly add anhydrous acetonitrile that is twice the volume of the reactant in the container, and mix evenly to form a mixture. solution, distill off 3 / 4 of the volume of the solution under reduced pressure, and distill off the residual phosphorus oxychloride in the reaction vessel.

[0027] Add the N-methyl-N-propenylmorpholine quaternary ammonium salt ionic liquid of 500 milliliters / mole pentaerythritol and tribromoneopentyl alcohol (with the mol ratio of pentaerythritol being 3.0: 1) in the container, start st...

Embodiment 3

[0029] Similar to Example 1, put pentaerythritol and phosphorus oxychloride in a molar ratio of 1:7 into a reaction vessel equipped with a stirrer and a tail gas absorption device, turn on the nitrogen protection, stir at 60°C for 1.5 hours, and then heat up to 105°C Reflux for 10 hours. After the reaction is over, distill off excess phosphorus oxychloride under reduced pressure. After there is no liquid in the container, control the temperature of the system at 75°C, slowly add anhydrous acetonitrile that is 1.9 times the volume of the reactant in the container, and mix evenly to form a mixture. solution, 4 / 5 of the volume of the solution was distilled off under reduced pressure, and the residual phosphorus oxychloride in the reaction vessel was distilled off.

[0030]Add the N-methyl-N-propenylmorpholine quaternary ammonium salt ionic liquid of 300 milliliters / mole pentaerythritol and tribromoneopentyl alcohol (with the mol ratio of pentaerythritol being 1.8: 1) in the conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com