Preparation method and application of epoxy-terminated brominated polyether fabric flame-retardation finishing agent

A technology of epoxy-terminated brominated polyether and hydroxyl-terminated brominated polyether is applied in the field of preparation of epoxy-terminated brominated polyether textile flame retardant finishing agent, which can solve the problem of insignificant flame retardant effect and bromine content. Low problems, to achieve the effect of high bromine content, excellent flame retardant effect, simple and convenient process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

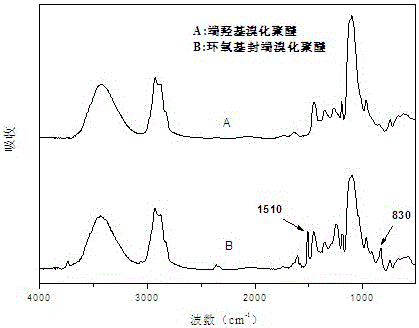

Image

Examples

Embodiment 1

[0024] 1) Put 30g hydroxyl brominated polyether, 15g epichlorohydrin, 1g tetrabutylammonium bromide, 6g potassium hydroxide into a flask, heat at 95°C for 12 hours, cool to room temperature, add chloroform to extract Filter, adjust pH to neutral with sulfuric acid, dry over anhydrous sodium sulfate, and remove unreacted epichlorohydrin through distillation to obtain 22g of epoxy-terminated brominated polyether resin;

[0025] 2) Dissolve 22g of epoxy-terminated brominated polyether resin obtained in step (1) and 0.2g of bis(4,4'-sulfidetriphenylsulfonium salt) hexafluorophosphate in 77.8g of acetone, and stir Until evenly, 100g of flame retardant finishing agent of the present invention is obtained;

[0026] 3) Soak the fabric in the homogeneous solution of the flame retardant finishing agent obtained in step (2) for 5 minutes, squeeze out acetone, repeat 3 times, and put it under the ultraviolet light for 5 minutes after drying.

[0027] According to the test of GB / T 17591-2...

Embodiment 2

[0029] 1) Put 20g of hydroxyl-terminated brominated polyether, 16g of epichlorohydrin, 0.8g of boron trifluoride ether complex, and 4g of sodium hydroxide into a flask, heat at 105°C for 8 hours, cool to room temperature, and add three Chloromethane suction filtration, sulfuric acid to adjust the pH to neutral, anhydrous sodium sulfate drying, after distillation to remove unreacted epichlorohydrin, obtained epoxy-terminated brominated polyether resin 30g;

[0030] 2) Dissolve 30 g of the epoxy-terminated brominated polyether resin obtained in step (1) and 15 g of triethylenetetramine in 55 g of acetone, and stir until uniform to obtain 100 g of the flame retardant finishing agent of the present invention;

[0031] 3) Soak the fabric in the homogeneous solution of the flame retardant finishing agent obtained in step (2) for 5 minutes, squeeze out acetone, repeat 3 times, and put it in an oven at 45°C to heat and cure for 3 hours.

[0032] According to the test of GB / T 17591-200...

Embodiment 3

[0034] 1) Put 25-terminated hydroxyl brominated polyether, 13g of epichlorohydrin, 1g of tin chloride, and 5g of sodium hydroxide into a flask, heat at 125°C for 6 hours, cool to room temperature, add chloroform and suction filter, Sulfuric acid was used to adjust the pH to neutral, dried over anhydrous sodium sulfate, and then distilled to remove unreacted epichlorohydrin to obtain 30 g of epoxy-terminated brominated polyether resin;

[0035] 2) Dissolve 30 g of epoxy-terminated brominated polyether resin and 24 g of polyamide in 46 g of toluene obtained in step (1), and stir until uniform to obtain 100 g of the flame retardant finishing agent of the present invention;

[0036] 3) Soak the fabric in the homogeneous solution of the flame retardant finishing agent obtained in step (2) for 5 minutes, extrude the toluene, repeat 3 times, and put it in an oven at 100°C for heating and curing for 40 minutes.

[0037] According to the test of GB / T 17591-2006, the combustion performa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com