Catalyst for preparing aromatic polycarboxylic acid

A technology of catalyst and polycarboxylic acid, which is applied in the direction of physical/chemical process catalyst, carboxylate preparation, metal/metal oxide/metal hydroxide catalyst, etc. It can solve the problems of low bromine consumption, high bromine content and low impurity content And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

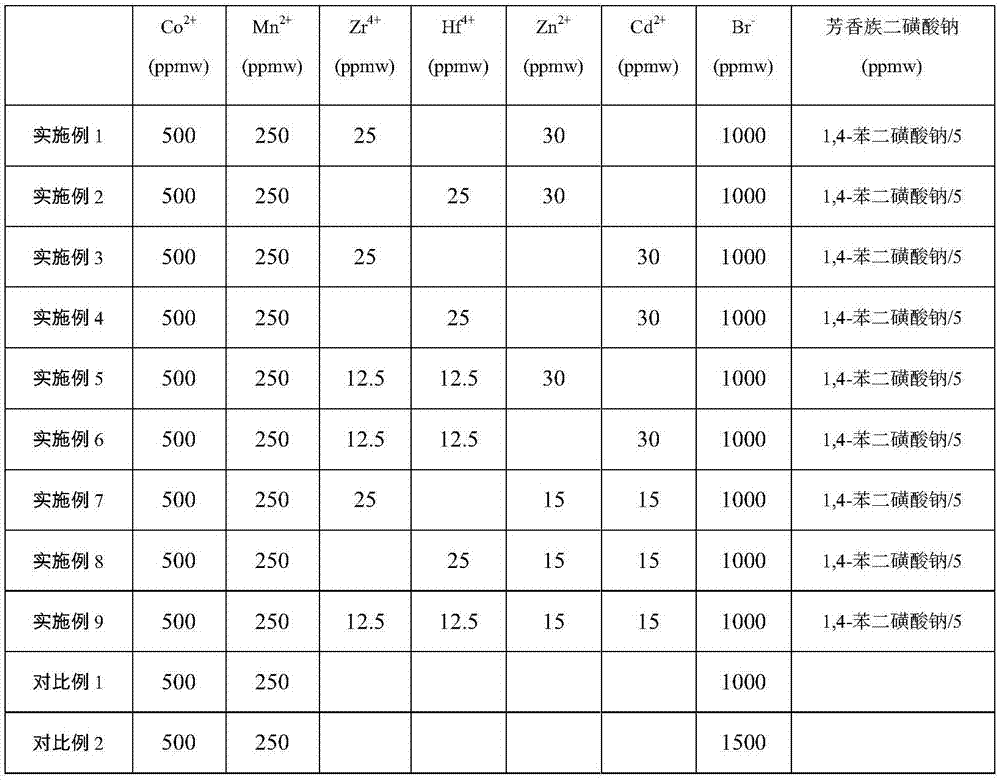

Embodiment 1

[0037] The reaction was carried out in a 1000ml titanium autoclave equipped with a magnetic stirrer, a gas delivery pipe, a reflux condenser, a thermocouple, and a bursting disc, with a stirring speed of 400rpm and heated by circulating hot oil. The reaction steps are as follows:

[0038] 1) Mix 80g p-xylene, 400g acetic acid and 20g catalyst acetic acid solution (containing cobalt acetate, manganese acetate, zirconium acetate, zinc acetate, 1,1,2,2-tetrabromoethane, 1,4-benzenedisulfonic acid Sodium) is added into autoclave after mixing evenly, and airtight; Wherein by weight of the mixture, containing 500ppmw Co 2+ 、250ppmw Mn 2+ , 25ppmw Zr 4+ , 30ppmw Zn 2+ , 1000ppmw bromine and 5ppmw 1,4-benzenedisulfonate sodium.

[0039] 2) Add 2.0MPa nitrogen to carry out the airtight test for 30 minutes, and the pressure drop within 30 minutes is not more than 0.1MPa, which is qualified.

[0040] 3) Add nitrogen, the mass space velocity is 4h -1 , and start the stirrer, the sti...

Embodiment 2

[0045] The reaction was carried out in a 1000ml titanium autoclave equipped with a magnetic stirrer, a gas delivery pipe, a reflux condenser, a thermocouple, and a bursting disc, with a stirring speed of 400rpm and heated by circulating hot oil. The reaction steps are as follows:

[0046]1) Mix 80g p-xylene, 400g acetic acid and 20g catalyst acetic acid solution (containing cobalt acetate, manganese acetate, hafnium acetate, zinc acetate, 1,1,2,2-tetrabromoethane, 1,4-benzenedisulfonic acid Sodium) is added into autoclave after mixing evenly, and airtight; Wherein by weight of the mixture, containing 500ppmw Co 2+ 、250ppmw Mn 2+ 、25ppmw Hf 4+ , 30ppmw Zn 2+ , 1000ppmw bromine and 5ppmw 1,4-benzenedisulfonate sodium.

[0047] 2) Add 2.0MPa nitrogen to carry out the airtight test for 30 minutes, and the pressure drop within 30 minutes is not more than 0.1MPa, which is qualified.

[0048] 3) Add nitrogen, the mass space velocity is 4h -1 , and start the stirrer, the stirrin...

Embodiment 3

[0053] The reaction was carried out in a 1000ml titanium autoclave equipped with a magnetic stirrer, a gas delivery pipe, a reflux condenser, a thermocouple, and a bursting disc, with a stirring speed of 400rpm and heated by circulating hot oil. The reaction steps are as follows:

[0054] 1) Mix 80g p-xylene, 400g acetic acid and 20g catalyst acetic acid solution (containing cobalt acetate, manganese acetate, zirconium acetate, cadmium acetate, 1,1,2,2-tetrabromoethane, 1,4-benzenedisulfonic acid Sodium) is added into autoclave after mixing evenly, and airtight; Wherein by weight of the mixture, containing 500ppmw Co 2+ 、250ppmw Mn 2+ , 25ppmw Zr 4+ 、30ppmw Cd 2+ , 1000ppmw bromine and 5ppmw 1,4-benzenedisulfonate sodium.

[0055] 2) Add 2.0MPa nitrogen to carry out the airtight test for 30 minutes, and the pressure drop within 30 minutes is not more than 0.1MPa, which is qualified.

[0056] 3) Add nitrogen, the mass space velocity is 4h -1 , and start the stirrer, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com