Process for producing octabromodiphenyl ethane

A technology of octabromodiphenylethane and diphenylethane, which is applied in the field of preparation of octabromodiphenylethane and achieves the effects of high bromine content, small investment and simple reaction control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

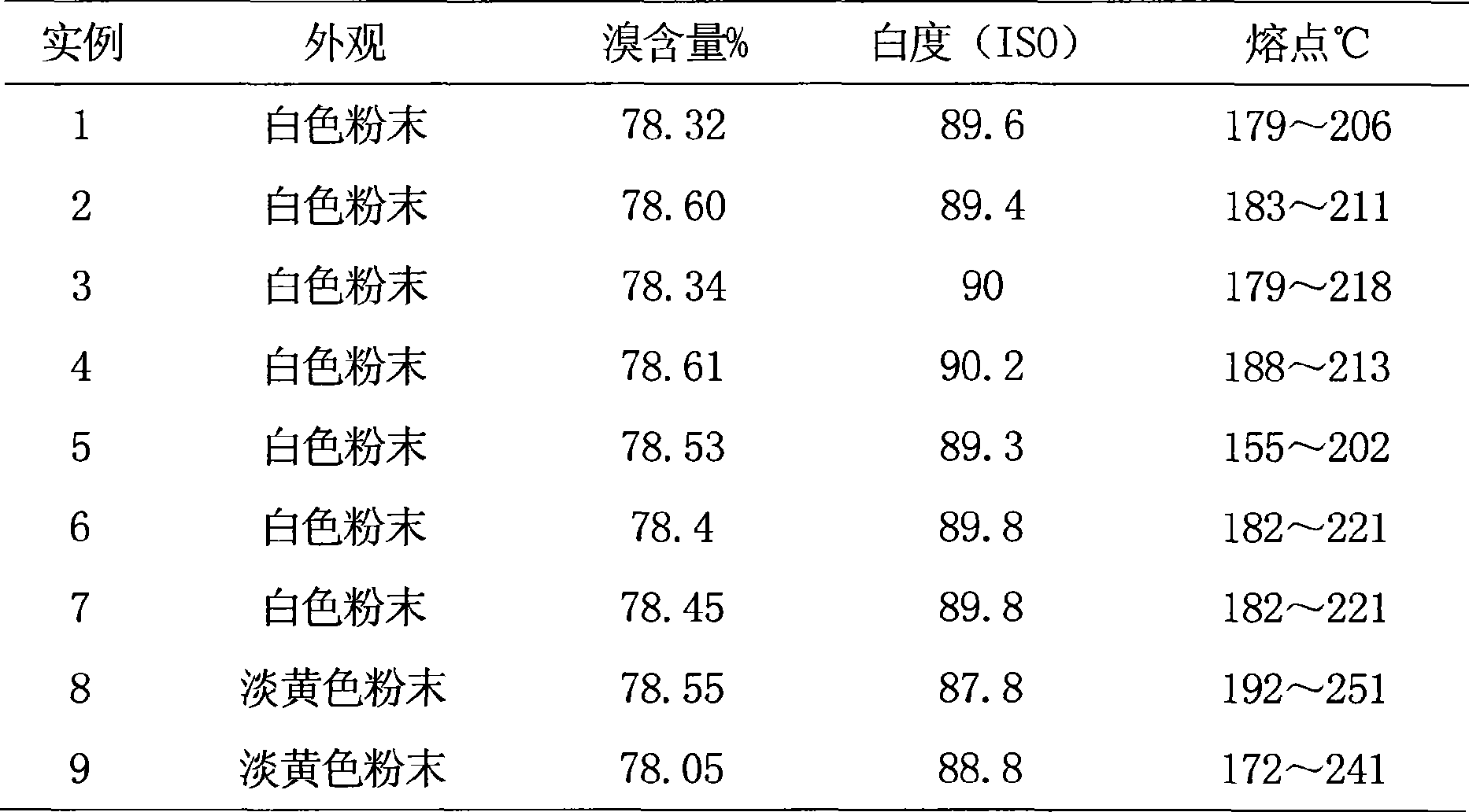

Examples

Embodiment 1

[0024] Add 0.9 g of aluminum powder to 500 g of liquid bromine, stir and react for 20 minutes to generate a reaction mixture A of bromine and aluminum powder; The addition time was 15 minutes. After the dropwise addition was completed, the stirring reaction was continued for 0.5 hours at a temperature of 5° C. to obtain a mixture B; under stirring conditions, 120 grams of water and 0.6 grams of ethylenediaminetetraacetic acid were added to the above mixture B, and stirred for 30 Minutes later, the mixture C was obtained; the above-mentioned mixture C was distilled under the condition of negative pressure -0.06Mpa. When the temperature rose to 77°C, the distillation was completed, and then the product after the distillation was suction filtered to obtain 44 grams of crude octabromodiphenylethane; Add 110 grams of water and 0.88 grams of solid caustic soda to the above-mentioned crude product of octabromodiphenylethane, then carry out wet pulverization, and after wet pulverizatio...

Embodiment 2

[0026] Add 1.1 g of iron powder to 500 g of liquid bromine, stir and react for 22 minutes to generate a reaction mixture A of bromine and iron powder; The addition time was 20 minutes. After the dropwise addition was completed, the stirring reaction was continued for 0.5 hours at a temperature of 4°C to obtain a mixture B; under stirring conditions, 150 g of water and 1.0 g of sodium edetate were added to the above mixture B, and stirred After 32 minutes, the mixture C was obtained; the above-mentioned mixture C was distilled under the condition of negative pressure -0.07Mpa. When the temperature rose to 76°C, the distillation was completed, and then the product after distillation was filtered with suction to obtain 53.2 grams of crude octabromodiphenylethane Add 128 grams of water and 2.4 grams of sodium sulfite to the above-mentioned octabromodiphenylethane crude product, then carry out wet pulverization, and after wet pulverization for 9.5 hours, carry out suction filter, ob...

Embodiment 3

[0028] Add 1.3 g of a mixture of aluminum powder and iron powder to 500 g of liquid bromine, and stir for 25 minutes to generate a reaction mixture A of bromine, aluminum powder and iron powder; 14 grams of diphenylethane, the dropwise addition time is 22 minutes, after the dropwise addition is completed, the stirring reaction is continued for 40 minutes at a temperature of 5° C. to obtain a mixture B; under stirring conditions, 160 grams of water and a concentration of 4 grams of 30% hydrochloric acid, after stirring for 34 minutes, mixture C was obtained; under the condition of negative pressure ~ 0.075Mpa, the above mixture C was distilled. When the temperature rose to 75°C, the distillation ended, and then the product was filtered and distilled to obtain eight Brominated diphenyl ethane crude product 59.99 grams; Add 132 grams of water and 3.9 grams of soda ash in the above-mentioned octabromodiphenyl ethane crude product, carry out wet pulverization then, after wet pulveri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com