Pre-treatment and dyeing method for natural crystal fibers and blended or interwoven products of natural crystal fibers and other fibers

A dyeing method and fiber blending technology, applied in the processing of textile materials, continuous processing of textile materials, textiles and papermaking, etc., can solve problems that have not been systematically researched and applied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

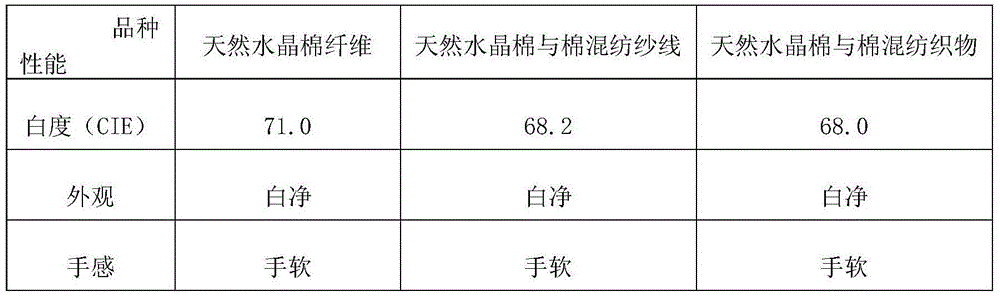

Examples

Embodiment 1

[0070] A method for pretreatment and dyeing of natural crystal cotton fiber and cotton fiber blended products, comprising the following steps:

[0071] 1), pre-treatment: two-step continuous method - desizing, boiling and bleaching combined method: padding and desizing solution, padding is one dipping and one rolling or two dipping and two rolling; stacking at room temperature for 4 to 12 hours or 95 Steaming above ℃ for 20-90 minutes; washing and drying; padding and boiling liquid, padding is one dipping and one padding or two dipping and two padding; stacking at room temperature for 4-12 hours or steaming above 95°C for 20-90 minutes; washing treatment To neutral pH, dry;

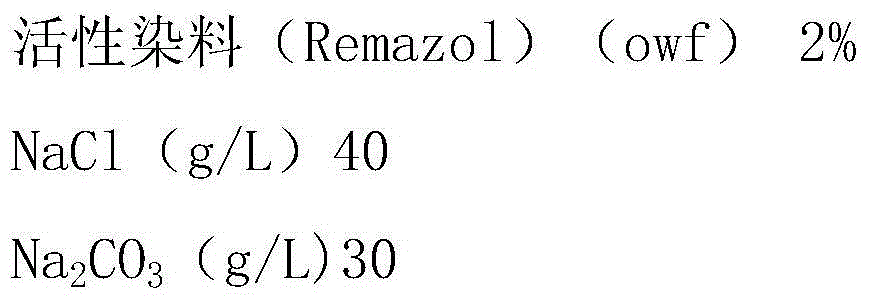

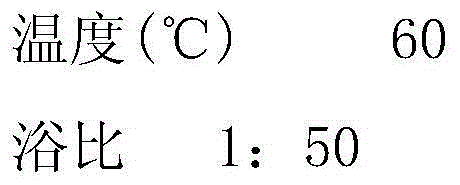

[0072] 2), Dyeing: Dyeing with continuous reactive dyes:

[0073] Use reactive dyes, wetting and penetrating agents, urea, anti-swimming agents, and anti-staining salt S to prepare reactive dye dyeing solutions; padding dyeing solutions at room temperature, padding is one dipping and one padding or two d...

Embodiment 2

[0076] A method for pretreatment and dyeing of natural crystal cotton fiber and polyester fiber blended products, comprising the following steps:

[0077] 1) Pretreatment: The one-step continuous pretreatment process is as follows: preparation of pretreatment liquid; padding pretreatment liquid, padding is one dipping and one rolling or two dipping and two rolling, stacking at room temperature for 4 to 12 hours or at 95°C Steam the above for 20-90 minutes; wash with water until the pH value is neutral, and dry;

[0078] 2) Dyeing: One-bath two-step continuous dyeing process with disperse / reactive dyes:

[0079]Prepare disperse / reactive dye solution (disperse dye, reactive dye, penetrant JFC 0.5~1g / L, urea 10g / L, 5% sodium alginate 1~3g / L, etc.) → padding solution (room temperature, one Dipping first rolling or second dipping and second rolling, the remaining rate is 60-70%) → pre-baking (infrared rays → hot air → drum drying) → baking (170 ~ 210 ° C, 1 ~ 2min) → (cooling) → p...

Embodiment 3

[0082] A method for pretreatment and dyeing of natural crystal cotton fiber and nylon fiber blended products, comprising the following steps:

[0083] 1), pre-treatment: one-step intermittent treatment:

[0084] Prepare pretreatment liquid, caustic soda or soda ash 10-40g / L, refining agent 0.5-5g / L, 100% H 2 o 2 10~20g / L, sodium silicate 5~10g / L, water softener or chelating dispersant 3~8g / L, room temperature~100℃ circulation treatment or immersion treatment for 30~90min, water washing and treatment until the pH value is neutral, to be dyed;

[0085] 2), Dyeing: One-bath pad dyeing with reactive dyes. Dyeing method:

[0086] Prepare dyeing solution with reactive dyes, surfactants, anti-swimming agents, anti-staining salt S, urea, etc.; pad dyeing solution; pre-baking; impregnation with fixing solution containing alkali agent and salt; steaming at 100-103°C for 2 ~3min; to be processed after dyeing;

[0087] 3), post-dyeing treatment: cold water washing; hot water washing;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com